SCM's latest Smart&Human innovations at WoodTech 2023

October 19-23, 2023 Tüyap – Istanbul

SCM, global leading producer of secondary woodworking machinery, confirms the participation of its subsidiary SCM Turkey (SCM Türkiye) in the next Woodtech Woodworking Machinery Fair, to be held from 19 to 23 October at Tüyap Exhibition and Congress Center, in Istanbul (Hall 3, booth 313).

WoodTech visitors will be able to find out the many advantages of a diversified proposal of cutting-edge technologies for every production requirement.

The SCM’s Smart&Human Factory concept will take centre stage: the solutions on display have been designed for highly customised, interconnected and sustainable production with a common objective: making the processes more efficient, simplifying control and keeping down costs, consumption and waste.

The cutting-edge technologies on demonstration will integrate with software and digital services at each stage of the machining process - preparation of data, planning, production, monitoring and assistance - to increase productivity and connect the entire process from the office to the factory.

TECHNOLOGIES HIGHLIGHTS

Routing and drilling: morbidelli m100

Highly modular 5-axis CNC machining centre that provides answers to all the problems associated with woodworking.

Unmatched finishing is possible thanks to the JQX (Just Quality eXtreme) 5-axis direct-driven spindle head which ensures the total absence of vibrations even with huge material removal at high speed and with the high-performance drilling heads with RO.AX (Rotoaxial spindle technology) spindles and rotation speed up to 8000 rpm.

Nesting: morbidelli x200

The ideal solution for flexible “batch 1” production as it permits nesting machining of pieces that are even shaped, and in a variety of sizes, with a cutting speed of up to 50 m/min and unprecedented productivity levels for this technology.

All the machining work is done without removing the spoil panel, even in 3D thanks to the X-POD suction cups. This dramatically reduces the machine's set-up times.

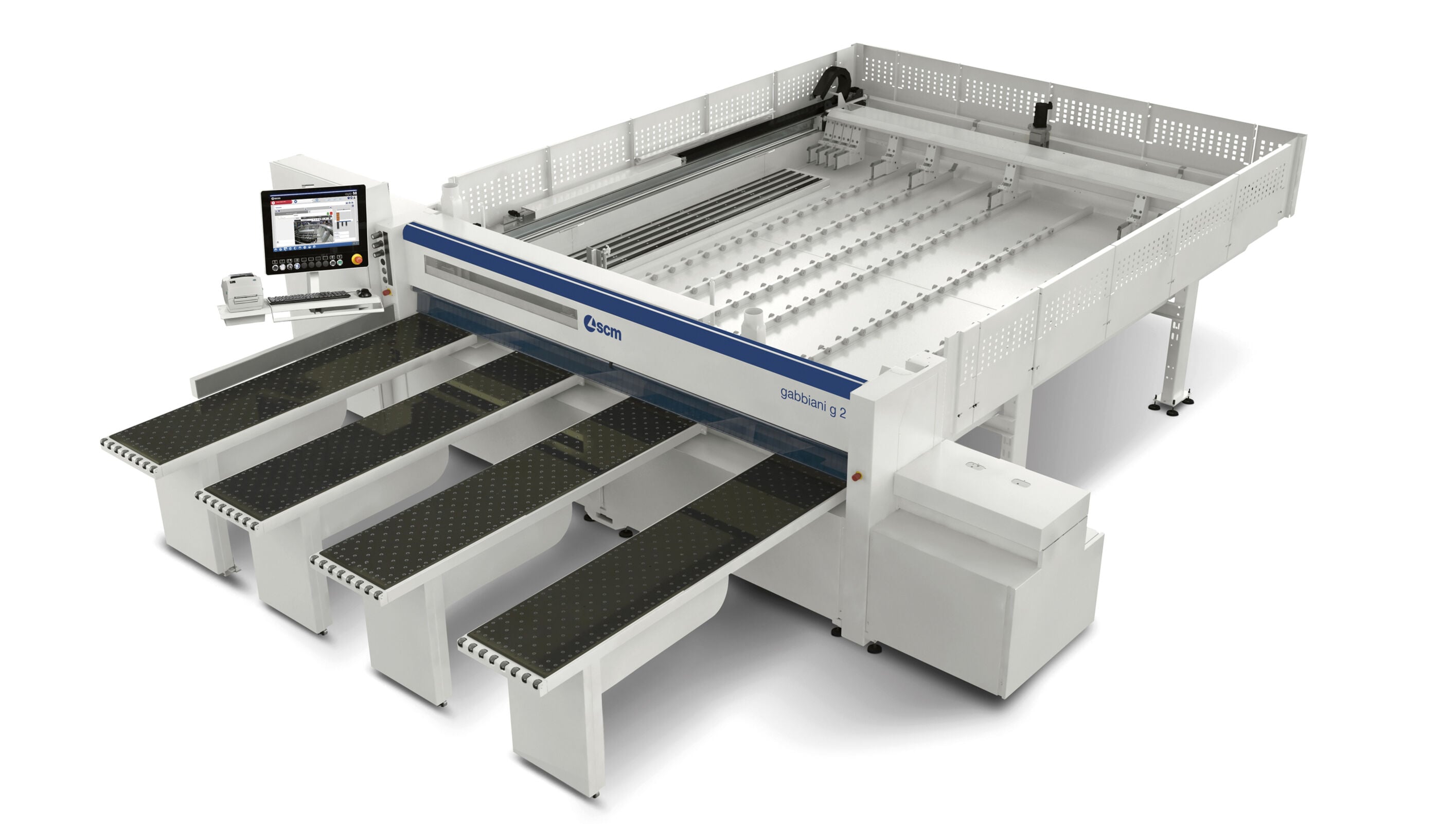

Beam saw: gabbiani g 2

Speed, precision, flexibility and high productivity mark out gabbiani g 2. It has been designed to assure high performance in a developed industrial context of just in time productions.

This beam saw allows for perfect cuts, even at the maximum high-speed, owing to the 15 kW motor supplied as a standard feature with RPM blade adjustment.

Edgebanding: stefani range for industry

stefani kd: the ideal edgebander for working different types of panels even with delicate surfaces thanks to the upper belt presser.

The SGP glue pot, fitted as standard, with the special anti-adherent plasma treatment, allows the use of two different types of glue, EVA and PUR for perfect edgebanding quality.

stefani md: the SGP glue pot, supplied as standard, guarantees a perfect joint line thanks to the special spreading roller and a perfect dosage of the glue and also allows the use of EVA and PUR glues with a fast and simple glue changeover.

Thanks to the working speed of up to 25 m/min and the possibility of processing more radii, stefani md is ideal for the industry that needs to continuously produce numerous different types of panels.

stefani x: designed to offer the highest quality of processing on any type of panel and material and to fully meet the needs of a digital, connected and integrated factory.

Stefani x offers TOP gluing quality thanks to the possibility of having two pre-melters at the same time, one for EVA glue and one for PUR glue.

Sanding: dmc sd 90

The RRCS configuration (calibrating roller, sanding roller, combi unit) ensures high flexibility and time saving and makes this machine perfect for both calibrating and sanding operations. It is the ideal solution for solid wood, veneered, lacquered and painted panels, it excels in the provision of an optimum level of finishing due to the “MESAR” electronic sectional pad.

Solid wood: superset nt

The ideal throughfeed moulder to carry out a wide variety of products: profiles for windows, doors, stairs, beads, frames and furnishings.

Increased productivity with the SET-UP system, which allows the operator to change tools and perform adjustments in just a few seconds, making set-up time up to 20 times faster.

Joinery machines

At woodtech, the most representative SCM joinery machines: class m 3 multiblade rip saw, nova si 400 circular saw, formula s 740p band saw, L’invincibile s 7 and nova s 520 thicknessing planers.