runner

(512) 931-1962

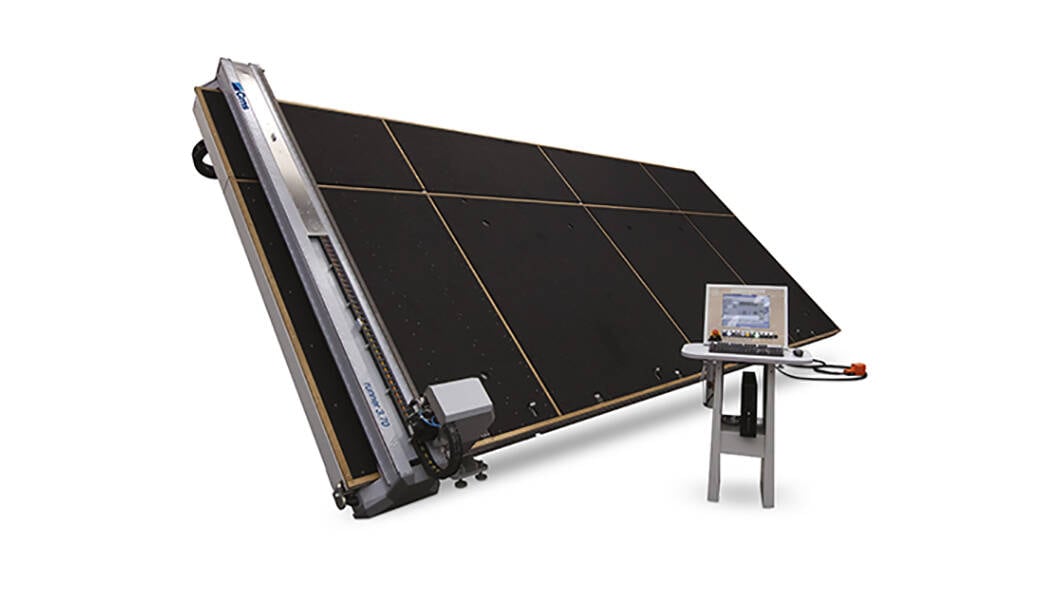

Runner is a tilting cutting table with three interpolated axes for straight and shaped cutting of flat glass plates with thickness ranging from 2 to 25 mm.

- Electrical and electronic equipment are completely integrated in the machine’s basement. This solution saves floor space, assures a very easy diagnostic of potential errors, and provides the utmost airconditioning system (air-conditioning system optional)

- Mechanical motorized tilting system of the work table makes it easy to load/unload glass sheets in small spaces and guarantees a long machine life, absolute reduction of maintenance and smooth movement.

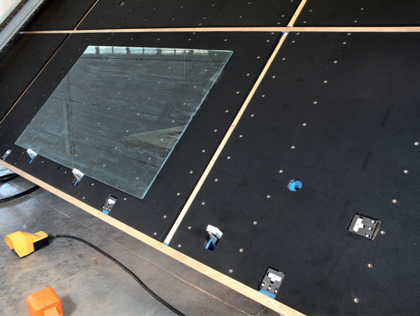

- High pressure turbine that generates an air cushion simplifying the handling of glass sheets; the air cushion can be set in two positions, depending on glass dimensions and thickness.

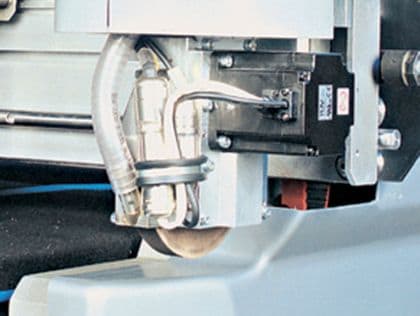

- Cutting head completely engineered by CMS with automatic control of the cutting pressure depending on glass thickness and oil flow according to the cutting speed.

- “C” axis included in the standard supply, guarantees the highest accuracy in shaped cuts.

FASTEST TILTING TABLE

The system for the overturning of type mechanical, with chain transmission, allows tipping times of less than 20 seconds. Unlike hydraulic systems, maintenance is zeroed.

NO SETTING TIME

Thanks to the patented four-head system for automatic management of cutting of different thicknesses, no manual operation is required. Each head carries a wheel that is specific for its thickness, guaranteeing zero stop times when changing the sheet.

COMPLETE REMOVAL OF THE LOW-E

The peripheral grinding wheel eliminates the low emissivity layer with speeds up to 80 m / min. The device is suitable for intensive use to work continuously with all types of Low-E.

| Model | 3.70 | 6.20 |

| Axex maximum stroke X-Y-C* |

4400 mm - 2600 mm - 360° 173 in - 102 in - 360° |

6900 mm - 3350 mm - 360° 272 in - 132 in - 360° |

| Useful working area |

4250 mm - 2560mm 167 in - 101 in |

6790 mm - 3310mm 267 in - 130 in |

| Workable Thickness |

2 - 25 mm 1/13 in - 1 in |

2 - 25 mm 1/13 in - 1 in |

| Accuracy and Repeatibility | ± 0,20mm / ±0,15mm | ± 0,20mm / ±0,15mm |

| Maximum speed and acceleration |

160 m/min - 5 m/s2 530 ft/min - 16 ft/s2 |

160 m/min - 5 m/s2 530 ft/min - 16 ft/s2 |

| Weight | 3500 kg / 7700 lb | 5100 kg / 11250 lb |

*Optional

Fill out the online form to be contacted by a salesperson