SCM has been a leader in the industry of woodworking technology for 70 years thanks to its ability to renew itself in line with the evolution of the market.

From this combination of experience and progress come SCM's systems for timber construction which are dedicated to the production of structural beams, X-lam/CLT wall elements, prefabricated walls and insulating panels.

Our technological solutions are designed and produced in the SCM plant in Sinalunga (Siena), a highly specialized industrial center covering 6,000 square meters, where each new machines are developed in accordance with the customer's specific requirements and the trends in the sector.

100% Made in Italy technology, based on the values of expertise and innovation.

SCM offers a range of CNC Machining centers equipped with several operating units dedicated to specific operations, which allow the production of prefabricated walls, trusses, roofs and blockhouses:

oikos xs CNC machining centers are distinguished by their high execution speed and advanced configurability. Designed for the production of laminated and solid wood structural components, they are particularly suitable for processing simple elements, such...

SCM offers a range of CNC Machining centers with a 5- and 6-axis operating unit to produce all types of beams, ideal for roof construction and structural applications:

oikos x is the CNC machining centre for the production of structural beams and X-lam/CLT wall panels up to 1250 mm wide. The innovative 6-axis operating unit allows any machining operation on all faces of the element in a single positioning and with...

oikos x+ is the new 6-axis CNC machining centre designed for the intensive production of straight solid wood and glulam beams, with maximum cross-sections of 1250x300 mm, ideal for roofs, residential buildings and public structures. This model offers all...

oikos xl+ is the new CNC machining centre for processing structural columns with a maximum cross-section of 1,250x610 mm, used in the construction of multi-storey buildings. The presence of an independent sawblade unit, in addition to the 6-axis...

SCM has strong know-how in the processing of CLT panels, which are now also used in the construction of multi-storey buildings for walls and floors. Thanks to the expertise acquired, we developed CNC Machining centers with a mobile gantry structure, Automatic wide belt sanders and Double-end profiling machines, i.e. specific machines for this application:

area x is the 5-axis CNC machining centre with mobile gantry structure, for the production of X-lam/CLT walls and floors as well as of curved glulam beams. It is characterised by the wide configurability of the worktable, available in five different bases...

area xl is the 5-axis CNC machining centre, with mobile gantry structure, for the industrial production of large format X-lam/CLT panels for wall, ceiling and roof elements. It allows fully automatic handling and processing of elements up to 400 mm thick...

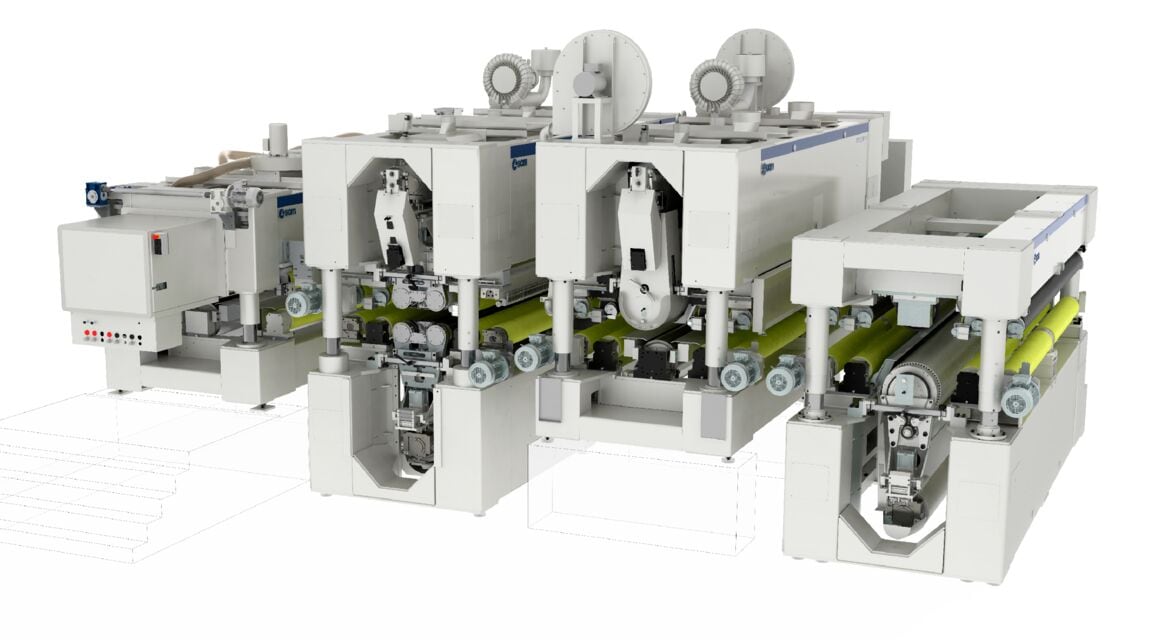

Automatic wide belt sander dmc system xl specifically designed for machining X-lam/CLT walls. Completely modular machine according to customer’s needs, it is able to process walls up to 3700 mm width and 500 mm thickness. dmc system xl thanks to its...

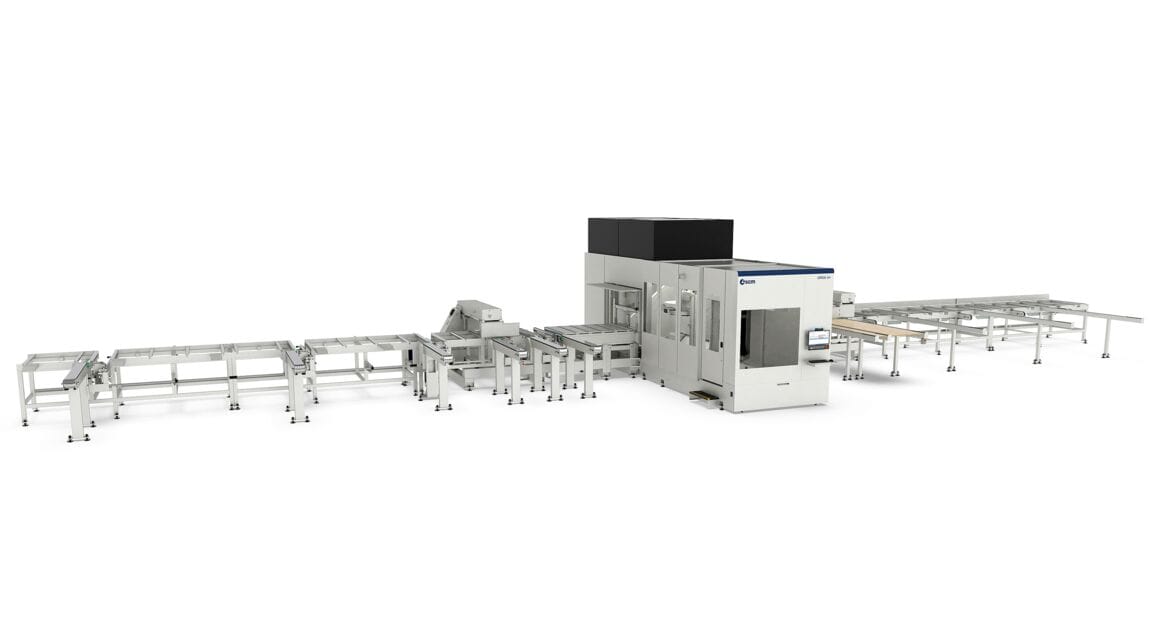

celaschi xl is the double-end profiling machine specifically designed for timber construction, combining structural strength with advanced technology, ensuring high performance even in the most challenging working conditions. It performs all the essential...

SCM's CNC Machining centers are characterized by total modularity, i.e. they can be configured according to the customer's requirements, and even allow the production of large elements: length up to 50 m and more, width 6,000 mm, thickness 400 mm.

These are ideal solutions for curved glulam beams that are used in large structures such as sports facilities and bridges.

Maestro beam&wall is the software developed by SCM that interprets files in standard BTL format, exported from the industry's leading CAD systems, and transforms them into programs that can be run on the machine. The system chooses the best machining strategies based on the available tools and operator preferences.

FROM SCREEN TO MACHINE! To carry out complex projects with the highest production efficiency.

Maximum workflow efficiency requires a simple and intuitive software that accompanies the operator at all times, from the programming phase, which can be carried out both in the office and the machine on board with eye-M operator console, to the creation of the elements that make up the project.

![]() EXTERNAL INTEGRATION

EXTERNAL INTEGRATION

Integration with the most popular CAD systems in the timber construction sector.

![]() PROGRAMMING FREEDOM

PROGRAMMING FREEDOM

Possibility to modify macros.

Easy tooling management.

![]() FAST WORKFLOW

FAST WORKFLOW

Automatic programming. Direct switch from project to machine program. 3D Representation of workpieces and machining steps.

![]() TIME-COST SAVINGS

TIME-COST SAVINGS

Elimination of collision risks, programming errors and downtime.

Calculation of real production time and costs.

![]() USER FRIENDLINESS

USER FRIENDLINESS

Simple and effective machine control via HMI software.