Aquanet

Technologien für den Möbelbereich

AQUANET, FROM SALES TO PRODUCTION

Aquanet, a Russian company that today employs almost 800 people and has reached numbers that have little to envy mass production enterprises, has decided to keep on expanding its production. The support of SCM’s staff has been fundamental in implementing this approach. “It is impossible to produce high quality painted furniture in large volumes, without modern industrial equipment”.

Machine tools are important, but a company’s success does not depend solely on them: being able to organise the production logistics is equally important. Aquanet, the Russian company that today is experiencing a crucial development, certainly not the first in its interesting story, is a prime example of this. “The company was set up twenty years ago”, began the tell us the owner Alexander Khramchenkov, who we met along with the representative of the main machinery supplier, the head of SCM’s Russian office Boris Chernyshev.

We are now going through the second phase of our expansion, that I consider the most important, a turning point: our production has reached the levels of a large mass production company. We have added two more plants to the main production plant, all under the same roof, thus creating a complete and indissoluble production cycle.

From the raw materials to the finished product, as far as the final delivery to the customer, we have optimised all the logistical chains”. “According to an ideal production method, an element should move as less as possible”, explains Boris Chernyshev. “It is not only more economical but it also improves the quality and safety of the final products.

Our technical office and our experts have developed and managed this project together for three years, building an optimal organisation, connecting the latest technologies with the equipment we had purchased in the past. Machine tools are important, but a company’s success does not depend solely on them: it is very important to organise the production logistics.

The excellent mass production will allow us to increase the productivity of the technological chain by up to 50%, without changing a fleet of machines. In May it was reorganised in order to remove all imbalances in the production plant”. The new painting lines require great investments in equipment. “But it’s a fully justified cost because we obtain constant quality and greater economic convenience of the works”, explains Aquanet’s owner. Competitiveness is also improved, because it’s impossible to manufacture high quality furniture in high volumes without modern industrial equipment. In 1997 Aquanet started importing hydraulic systems, bath tubs, bathroom furniture and doors from Spain. To do this it set up a small wholesale company and started taking part in trade shows and exhibition, organising its sales stands and a small sales network of three shops.

“Visiting the suppliers’ factories and getting to know the production, I suddenly realised that we could do something similar in Russia”, said Khramchenkov. His Spanish friends tried to put him off: “Why do you want to complicate your life? Don’t start with production, your sales are going well, buying and selling, everything is perfect”. “They were right in some respects, but our move from selling to producing happened over time. We gradually shifted from supplying prefabricated furniture to importing the assemblies (so that we could load more stock on the trucks and bring down the transport costs), this is why we had to buy a press for assembling. The next logical step was importing only the doors from abroad, ordering the frames in Russia”.

Subsequently the company needed to move the production from the rented property to a new plant. Seeing as I was born and grew up in Obninsk, I contacted the local authorities directly and they found us a location, right here where we are talking now. The production began here in a warehouse of 600 square metres. Today our total surface is 5 hectares”.

The assembly and painting departments are fundamental. “We previously used this department to renovate damaged doors and when we realised all the advantages of painting inhouse, we purchased our first painting cabin in Italy. For a while we acquired experience, until we decided to stop buying the frames from others and started organising our production. This is when we started buying the first pieces of equipment”.

Along with furniture, Aquanet sold acrylic bath tubs. “Everything was done in a similar way: we started importing pre-made Spanish products, then we imported the assemblies to assemble them locally until, in 2004, we met 40 the Slovenians at a trade fair and we decided to embark on a joint project. We initially invested in the first CMS br5 hp (Scm Group) thermoforming machine and started producing 100, then 200, then 300 articles per month. We efficiently passed our breakeven point which, according to our calculations, was 650 bath tubs per month. Last December we reached a production capacity of 24,000 articles. These numbers place us amongst the leading three companies of the sector in Russia.

Bringing together production and distribution was very difficult at the start. But now the difficulty has been fully overcome. “Today we have 23 shops and we count on having 45- 50 in Russia in 2019. The highest growth has been in the central regions. Six months ago we opened an office and a large shop with warehouse in Astana, and now we want to open another shop in Kazakhstan”. The collaboration with SCM lasts for more than 10 years. “We put our trust in this supplier, who was able to provide us with all the necessary equipment”, commented the Russian businessman. “After purchasing the initial machine tools, with the advice of some SCM colleagues, we started organising our company in a more structured way”.

“We implemented two projects”, continued Boris Chernyshev. “First of all, based on the technical settings and taking into account the plant’s capacity, we suggested a series of machines for the full production of furniture: panel sizing, drilling and edging”. The other purchases, such as the 5-axes machining centre used to machine the curved laminated doors, bought from SCM in 2012, came gradually, in line with the company’s growth. “The second great project has been completed recently and it involved the installation of automatic high performance painting cabins in a separate room. The development underwent various stages”, continued the owner. “We paid for everything that you see now ourselves. We didn’t take out any loan because we wanted to live within our means and make further investments based on our capacity”.

Two automatic lines for complete painting Superfici are fundamental in this project - including the first in Russia spraying machine Magnum with the most effective and innovative water filtration system. But why make life more complicated? “If you are successful, it’s absolutely impossible to stop halfway. If you stop developing and investing in the future, you will quickly drop down to the lowest level. You must be constantly up to date. There are only two options for us: develop or close, there isn’t a third”. Growing for this Russian company is also an act of responsibility towards its employees and collaborators. “Today we employ about 78 workers and their families. We produce excellent products and our company has received numerous awards. Overcoming day to day problems means truly living”.

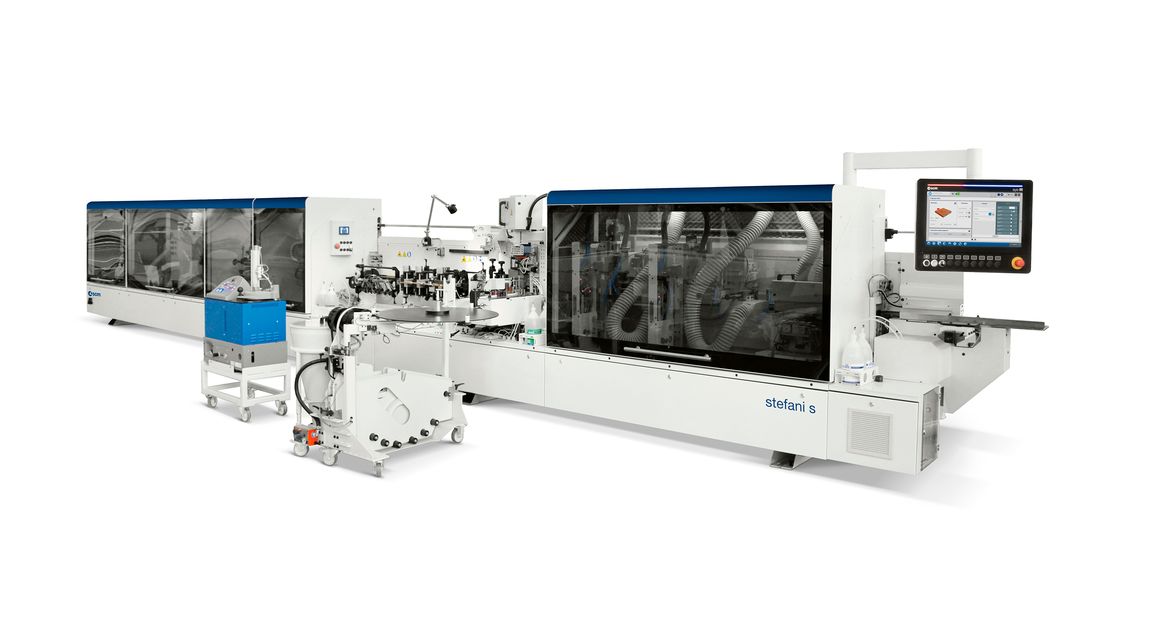

“Most of our high-performance machines tools are Italian, because Italy has always been the leader in furniture production. This is why we chose SCM, after having examined in detail the productivity, technological ability, reliability and flexibility of the equipment produced by the main European manufacturers”. SCM has sold Aquanet automatic single-blade beam saws gabbiani gt 3 with the loading rear table, two CNC machining centers morbidelli n200 dedicated for nesting process with "High Efficiency" work tables, three CNC drilling centers ux200 and three single-sided edgebanding machines stefani s.

The aftersales service is equally important to the company. “We can’t afford down times. The production is like a living organism: when an organ is ill, it involves the entire organism. This is why we chose the SCM technicians, who are specialised in the technical support service, with an enormous wealth of experience and knowledge. SCM responds to our technical support issues promptly and provides a complete range of spare parts and accessories for our equipment”.

Text and photos credits: Maxim Pirus, editor in chief LesPromInform

Aquanet

Bitte füllen Sie das Formular aus, um weitere Informationen zu erhalten