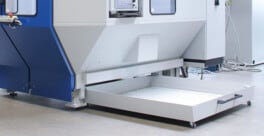

RT-F 1400 Compactness and performance at your service

Dec 4, 2024RT-F 1400 is the ideal 5-axis CNC machining center with rotary table for machining workpieces with dimensions up to 1000x800x400 mm, for sectors such as motorsport, automotive, marine and aerospace.

Its compact design means it can be installed even in small spaces, the control panel is adjustable and built in, and the rotary table that performs the C-axis motion allows dynamic milling and offers excellent results in terms of workpiece precision.

Excellent dynamics and minimal movement ensure maximum efficiency and short cycle times; the new HG Grimme design has become part of the wide range of solutions available from CMS.

• Fully enclosed dust-resistant cabin with integrated windows for better work area monitoring during the milling process.

• Built-in adjustable control panel with a simple user-friendly interface.

• Liquid-cooled high-frequency spindle with two shafts so that one tool can be installed on each side.

• Chip collection system with removable side tank to ensure that the machine can be cleaned quickly.

• Manual or automatic sliding doors provide free access to the machine table, making tooling and unloading easier.

• Touch probe.

• Roof to contain dust and noise.

• 12-position tool changer magazine equipped with protection to ensure excellent isolation from machining dust and residues.

• Operating unit with automatic tool changer spindle equipped with an extraction hood.