New brembana kosmos: CMS 5-axis monobloc milling machine

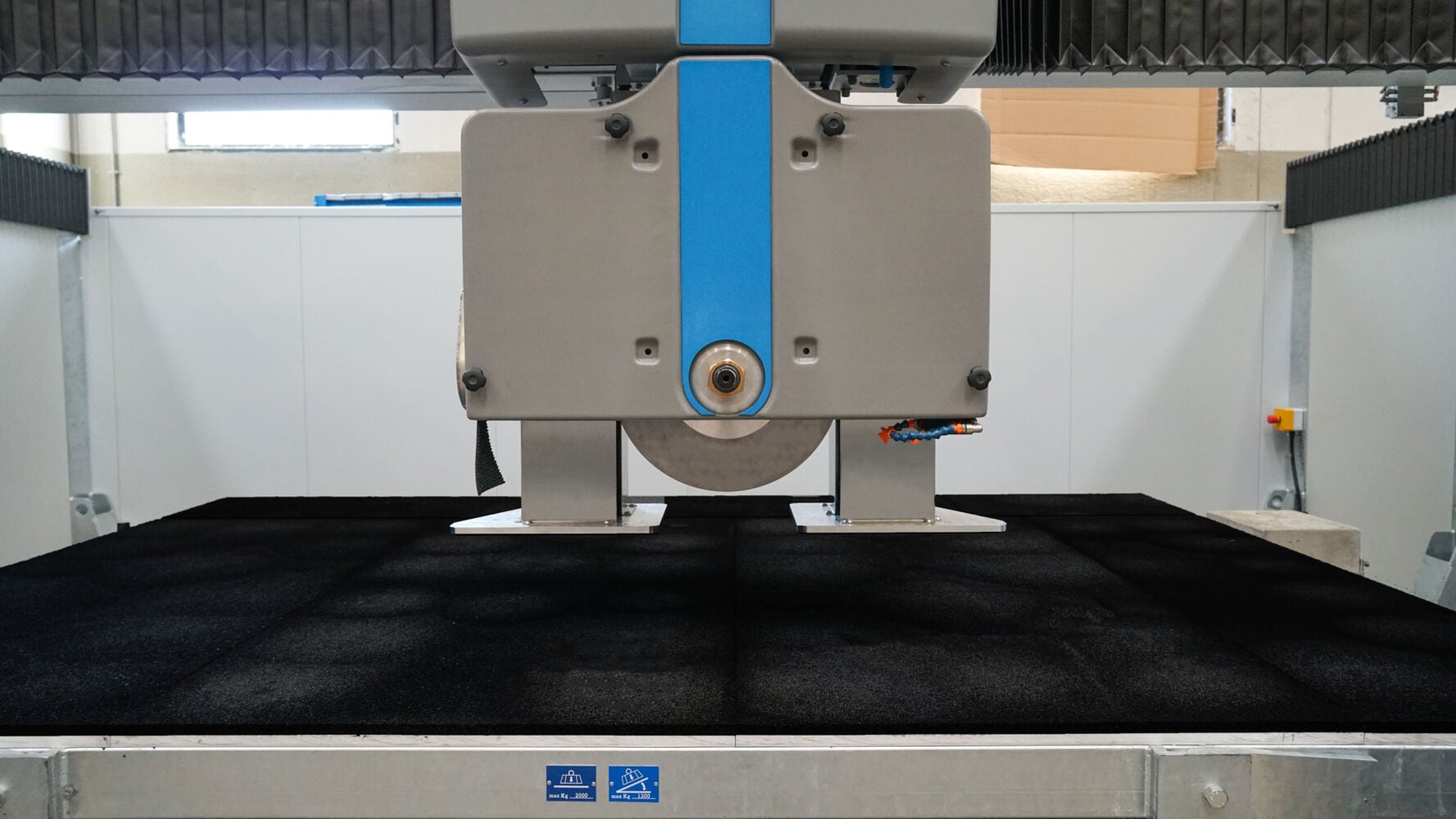

Nov 20, 2024Brembana kosmos is the CMS monobloc 5-axis milling machine designed for fabricating with ceramics, natural stone and synthetic stone slabs and blocks up to 200 mm thick.

Its compact structure allows easy installation and possible future relocation, while its heavy weight ensures great rigidity, making it ideal for kitchen worktops, bathroom tops, surface cladding, flooring, thresholds, stairs, windowsills and street furniture.

MAIN FEATURES:

• SUCTION CUP MANIPULATOR

This can move elements up to a maximum weight of 500 kg, and can be used with disks up to 625 mm. Its “nesting” cutting programs minimize machining waste, while its automatic cutting and motion increase productivity.

• NEW TILTING WORKTABLE

It has a maximum capacity of 1,200 kg, is operated by two hydraulic cylinders, and its motion is controlled by an inverter to ensure that it is always very smooth. The coating material can be selected from rubber, wood and cutting mat.

• MONOBLOC OR OPEN FRAME

The machine can be configured as a monobloc or with an open frame structure for installation on concrete columns.

• INTERFACE AND PANEL PC

With both manual and touch-screen controls and a large 21.5” screen, it offers more user-friendly management of the installed software. The installed interface makes programming simple and intuitive.

• CMS CONNECT

The CMS Connect digital service is included at no additional cost for the first year. CMS Connect is the IoT platform that displays, analyzes and monitors all data from connected machines in real time, turning it into information that can be exploited to increase productivity and to reduce operating and maintenance costs.

Other available ACCESSORIES:

• CAMERA

This is a system to capture images of the worktable, which speeds up stone workpiece positioning and helps detect any defects in the slab.

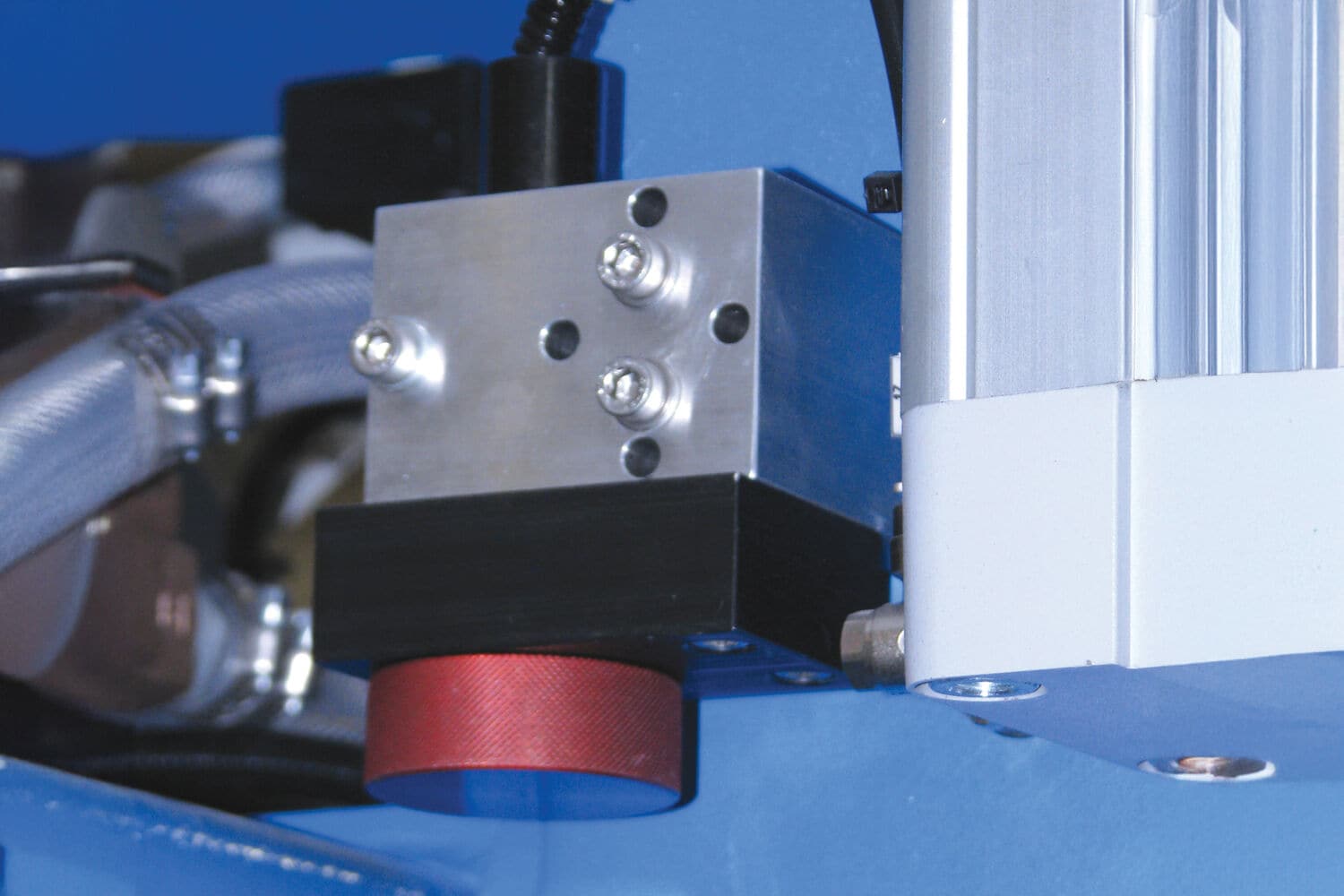

• DISK DIAMETER PRESETTING

This automatically acquires the diameter of the disk and the lengths of the cutters and drill bits.

• THICKNESS PROBE

This is used to automatically measure the thickness of stone or ceramic slabs.

• AUTOMATIC DRESSING

A special function on the operator panel can activate automatic disk dressing.

• CROSSHAIR LASER

This is used to quickly and easily define the workpiece origin or to acquire a two-dimensional shape for use in subsequent fabrication.

• UNIT FOR CUTTING FROM BELOW (for version on concrete columns only)

This allows automatic grooving cycles to be carried out on the bottom surface of the workpiece, e.g. for reinforcement bars in kitchen worktops made of natural stone.

KEY BUYER BENEFITS:

• +66% lifting capacity: the new manipulator can lift up to 500 kg, to handle larger and thicker workpieces.

• +50% load capacity: the tilting worktable has a capacity of 1,200 kg, to load more slabs at a time.

• Monobloc or open frame: also available for installation on concrete columns.