Pandoor Group

Technologies for Windows and Doors

Pioneers of the 4.0 Industry in the “Promised Land”

Pandoor Group, an Israeli manufacturer of doors for interiors, was the first in the industry to adopt automated lines integrated with robotics, which not only guarantee high volumes but also allow for high quality products to be achieved and customised according to the individual client’s needs. The most recent line purchased from SCM applies the most evolved technologies for surface treatment to create laminate painted doors

A continuous investment in Research and Development, constant attention to the quality of materials and technological processes adopted and an innovative, far-sighted approach capable of picking up on new market trends and, in many cases, anticipating them. These are the secrets to the success of Pandoor doors for interiors, designed for houses, offices, hotels and, more generally, for a clientèle that is highly sensitive to focusing on the design and product. Even a door for interiors, if manufactured in line with the highest aesthetic and quality criteria, plays a key role in creating an elegant, sophisticated environment where details count.

Pandoor Group understands this well. An Israeli manufacturer in the industry with 250 direct employees and another 200 collaborators with exclusive rights. Established in 1989, this group has always been at the forefront in Israel and the Middle East not only with the development and production of innovative products, but also the choice of state-of-the-art production systems, showing itself in many aspects as a genuine pioneer in the Promised Land. “We were the first in Israel to produce painted laminate doors with polymer frames that were highly water resistant” claims their vice president Anatoly Vays. Nowadays, the company led by Udi Gat, produces around 200 thousand doors per year, for the mid to top end of the market and exclusively at national level. “We prefer to sell our doors in Israel as this allows us greater margins” adds Vays, thus explaining the sales choice adopted. The identikit of the Pandoor client varies greatly and can be private individuals, salespersons or contracts. This involves the need to satisfy different requirements and specifications, according to the case in hand, although there are a few aspects common to all those in the Pandoor target. “Nowadays, the market tends to prefer a clean-cut design, an essential colour like white and painted doors” explains Vays.

The Pandoor brand knew how to become a genuine point of reference in the market thanks to the company’s ability to develop and produce lines of doors that are always state-of-the-art. Focus on the product starts with the raw material which is of a very high quality and imported from abroad, and continues with the use of evolved technologies, for each stage of the production cycle: from pressing to square-edging and from boring to painting. Innovation at product as well as process level. “Having state-of-the-art technological solutions to hand means being able to guarantee good accuracy with results which are increasingly favourable for our clients". This is the explanation behind another of Pandoor Group's strong points: a high level of automation perfectly in line with the new 4.0 Industry demands. The Israeli company acted as a guide even on this front as it was the first one in Israel to adopt the lines integrated with robot and RFID (Radio-Frequency Identification, in other words, bar code identification) technologies at its new plant for the production of wooden doors. This way, a more rapid production was guaranteed and, at the same time, a highly “customised” one, according to the needs and tastes of the individual clients, though always with high levels of precision and attention to the finishing and design of the end product.

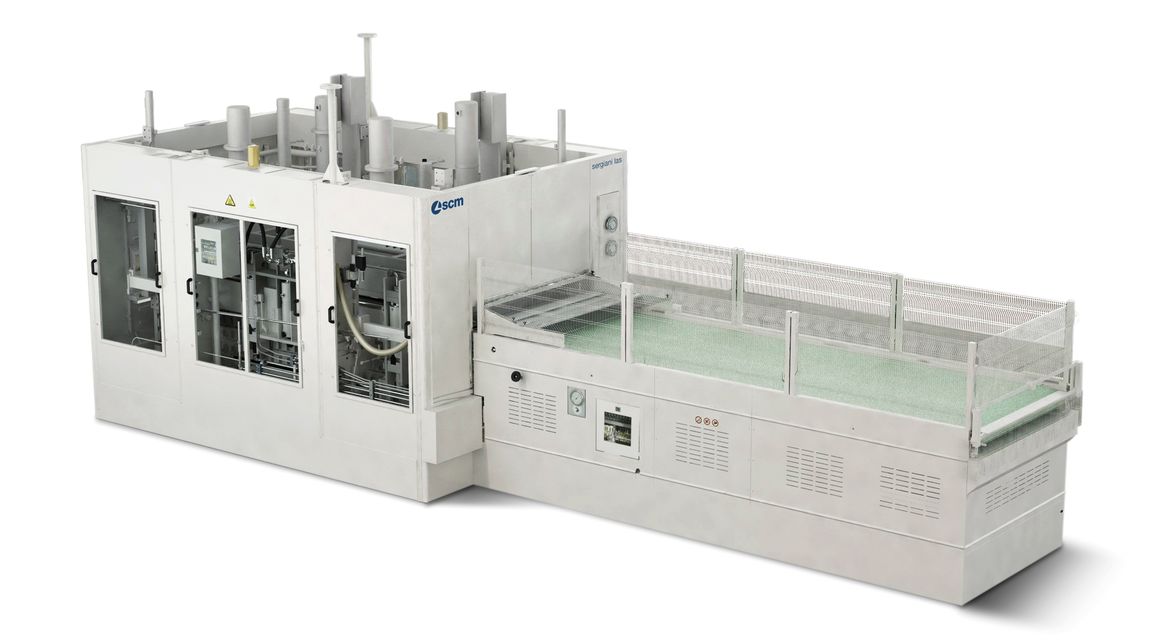

The new Pandoor Group plant is equipped with an entirely automated line controlled by SCM best-in-class Supervision software. Built around the Superifici valtorta f1 roller coating solution, the line also features Superfici UV drying system, and flexible abrasive technologies from SCM such as dmc sanders for surface treatment.

“Everything that can improve the quality of our product is of interest to us” underlines the vice president of Pandoor Group. The integrated SCM lines are the winning combination that allow us to achieve high standards of quality: the surfaces need to be smooth and even and free of any imperfections. A good preparation of the raw product makes the subsequent stages easier and produces advantages in financial and qualitative terms. On the contrary, poor preparation will often definitively compromise the paint work. The paint work, using the UV method not only provides an advantage of being highly customised but, over time, makes the end product extremely resistant to colour change following exposure to light sources.

“This line is currently at the creation stage and we hope to have it in production by June 2019. This is added to other SCM models, like the sergiani las for pressing and the stefani sb edgebanding line with automatic loading and unloading. Its special composition also allows for finishing work to be carried out and, as a result, a complete process on three sides of the door (sides and upper). This avoids manual intervention for finishing work.

“We decided to make this investment to increase our production capacity of painted doors, but above all, we chose an Italian company like SCM because our client particularly appreciates the Made in Italy” adds Vays.

Pandoor handles the entire process for its clients, from design to installation, and therefore has to optimise its own factory making the most of all the potentials offered by “smart manufacturing”. It is no coincidence that it is equipped with state-of-the-art digital software and services for a constant and detailed analysis of all the production parameters.

Pandoor Group

Fill out the online form to be contacted by a salesperson