Forum Holzbau International (IHF 2024)

04-06.12.2024 Innsbruck, Austria

SCM presents OIKOS X+, where precision and productivity meet

International Holzbau Forum (IHF) whose 28th edition is due to be held in Innsbruck (AT) from 4 to 6 December, is the culmination of a journey which, by attending the numerous editions of Forum Holzbau across Europe, has bolstered SCM’s interaction with the entire timber construction supply chain.

OIKOS X+, the latest new entry from the Italian group, will be presented at IHF 2024 and expands the range of CNC machining centres designed to optimise the production of wooden elements.

OIKOS X+ is the result of a constant commitment to R&D as well as the SCM team’s numerous years of know-how and its close attention to customers’ needs.

Get a preview of the SCM novelties, watch the video!

OIKOS X+ is still PLUS PERFORMANCE!

It is the CNC machining centre dedicated to the high volume production of solid wood and Glulam straight beams, with a maximum cross-section of 1,250x300 mm, ideal for the construction of roofs, residential buildings and public structures.

The machine features:

- a 6-axis machining unit with tool change designed to perform all the necessary operations on structural beams, wooden boxes and CLT panels with great flexibility and great finish quality.

- a 5-axis machining unit with a 900-mm diameter sawblade to guarantee better productivity and cutting capacity even on large beams, especially in notches which are increasingly deeper for structural applications.

This new solution increases the level of specialisation in the SCM OIKOS range, especially for the OIKOS X+ and OIKOS XL+ models.

OIKOS X+ is the perfect solution for carpenters working on laminated timber and looking for high productivity, while OIKOS XL+ has been designed for carpenters who work on Glulam glued to blocks as in the case with Mass Timber.

The two machines have been designed to meet customers’ different demands:

- Cutting depth: up to 300 mm (oikos x+) and 400 mm (oikos xl+).

- Thickness of the beams being machined: up to 300 mm (oikos x+) and 610 mm (oikos xl+).

DMC SYSTEM XL is BUILT BIGGER TO WORK HARDER

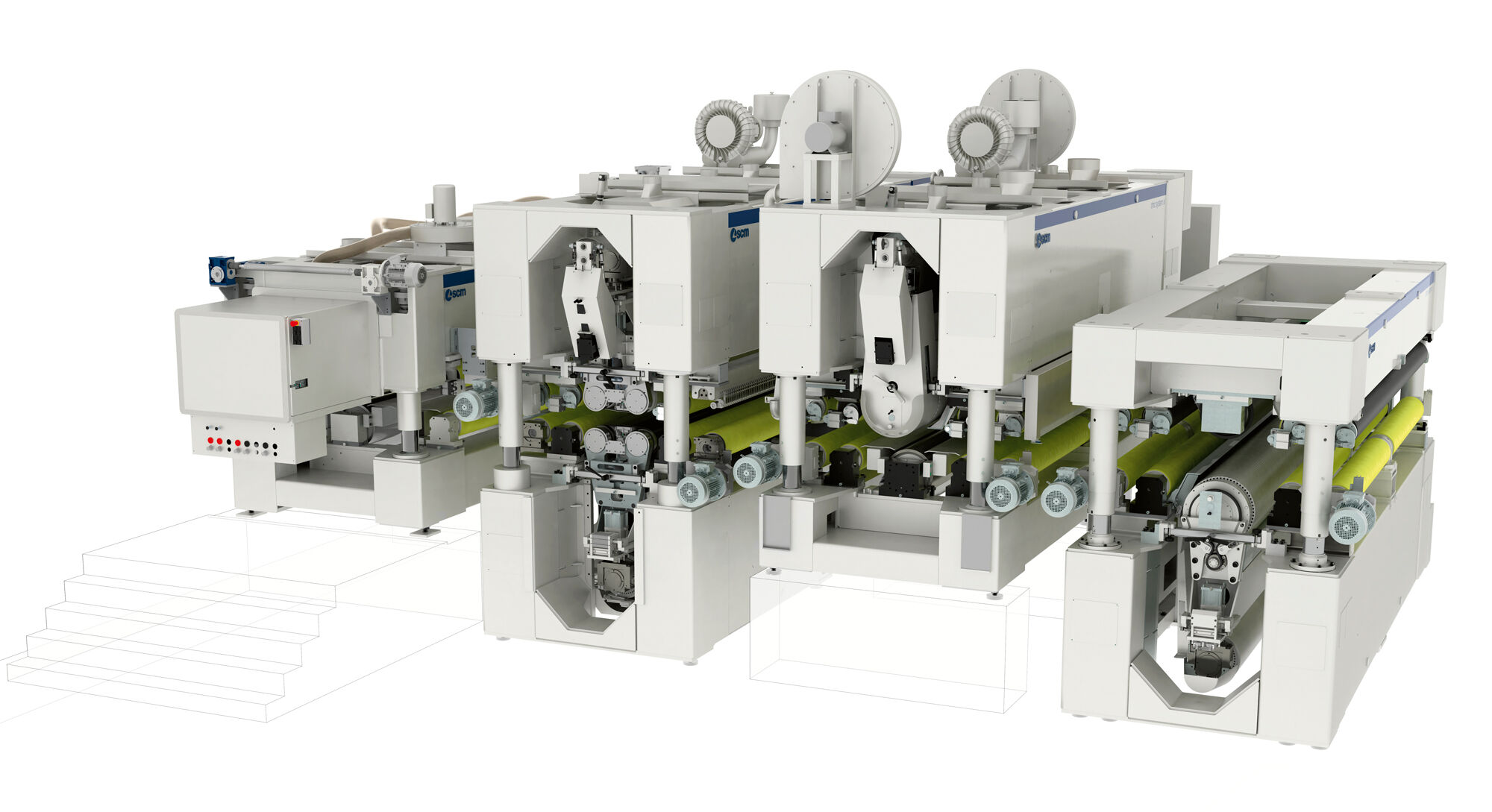

DMC SYSTEM XL, a highly modular automatic sanding-calibrating machine for processing CLT panels that can be employed in the timber construction sector.

The project is further enriched with three new units to process both top and bottom face of CLT panels up to 3.700 mm wide and 500 mm thick.

These modules can be fully combined and integrated with each other according to the customer's production requirements, for a high-quality finished product that reflects the latest market trends in having visible CLT walls.

SCM is not only a machinery supplier. SCM is your all-round partner to satisfy every production requirement and face even the most complex challenges of “green building”. Would you like to receive more information?