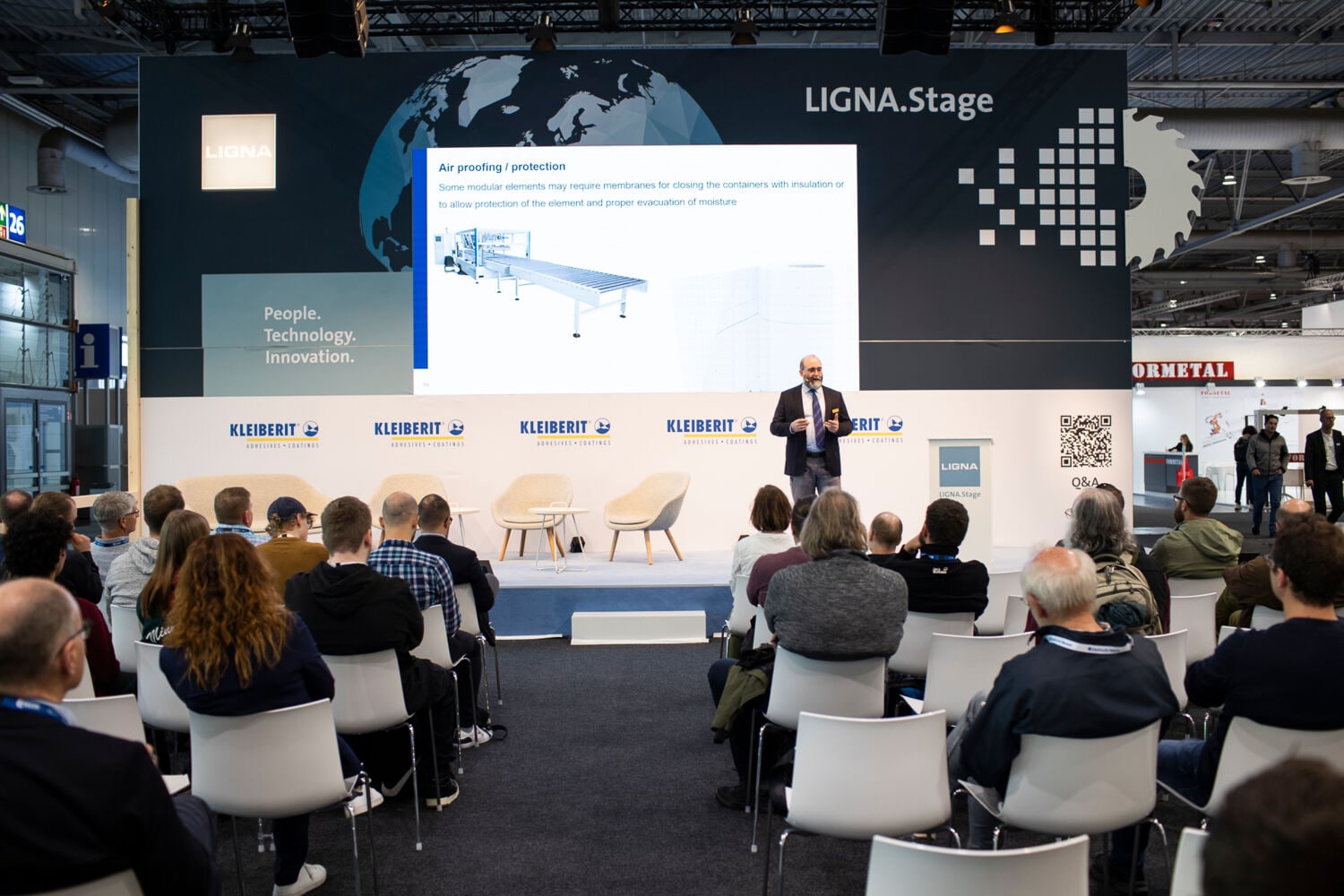

Can we construct a building as we produce furniture? The answer to Ligna.Stage

May 31, 2023The timber construction and prefabricated sector was one of the main themes of Ligna 2023. More eco-sustainable production processes, shorter times and a higher quality of workmanship are the demands that wooden construction is able to satisfy. Yet there are still some hurdles to overcome to achieve a large-scale diffusion of these buildings.

Is it possible to simplify construction techniques as it happens in the furniture industry? This is the question Thomas Aime, Product Area Manager France for SCM technologies for timber construction, wanted to reflect on from the stage of Ligna.Stage.

Thomas Aime starts from a premise: apart woodframe, a wooden construction cannot always be "pharaonic". Today most of the structural elements of a building in mass timber or CLT panels have considerable dimensions and weights that hinder a greater diffusion of these construction techniques in construction, especially for small and medium-sized projects.

The real keystone becomes modularity. A modern wooden construction - says Thomas - could be modular as a piece of furniture to become accessible and versatile while also optimizing the consumption of raw materials.

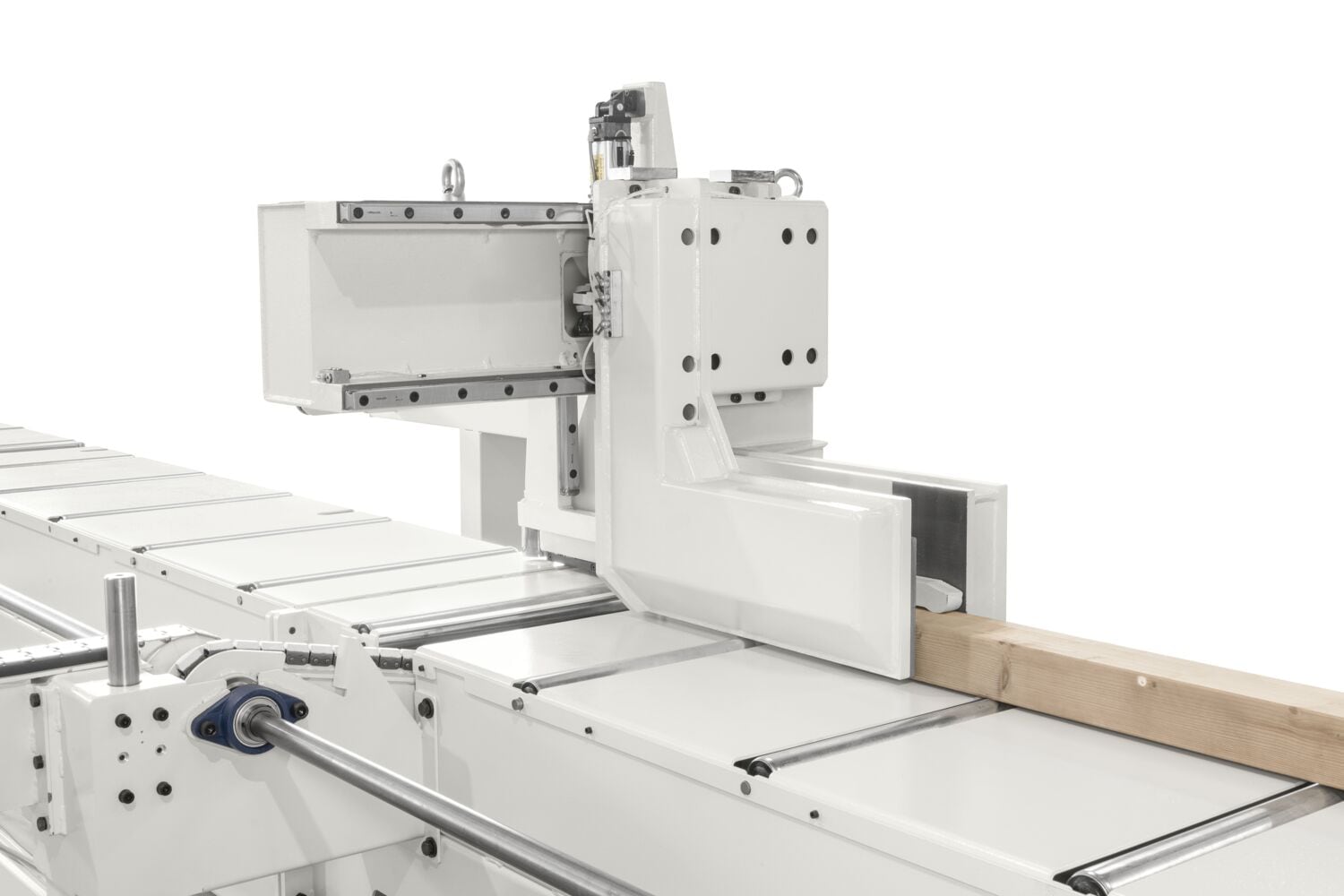

It is the same logic with which SCM approaches the sector: with a know-how of 70 years and a wide range of technologies for the industrial production of furniture that, combined with the exclusivity of the new 6-axis CNC machining centers for wooden construction, can make processes more efficient and sustainable.