stefani rocket H

(512) 931-1962

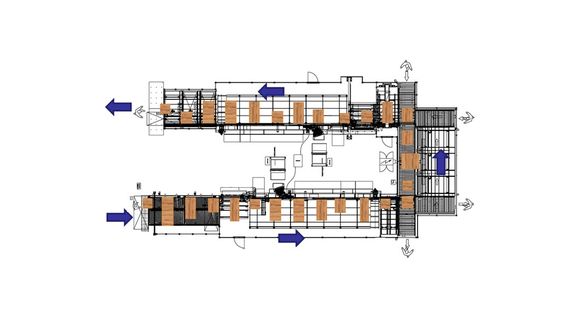

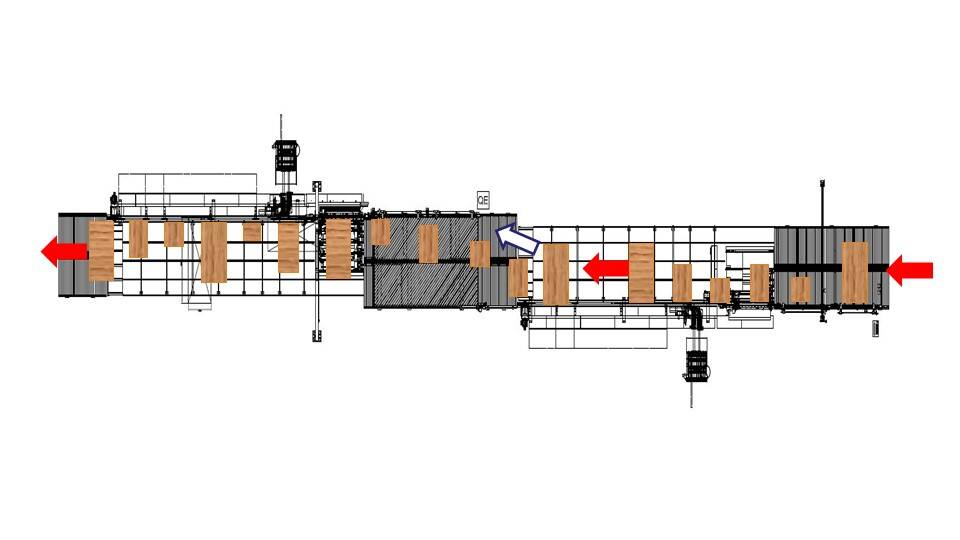

stefani rocket H is a flexible edgebanding and square -edgebanding line for the processing of panels already squared or to be squared with automatic introduction of the panel. It is a high productivity cell that meets the production requirements of companies where the process takes place with a "linear flow". The line guarantees the continuous flow of the process, a high production capacity and a high degree of flexibility allowing the introduction of panels of different sizes with the same thickness.

It is composed of the moover handling system and two single-sided edgebanding machines, stefani one or stefani sb one model, in left and right execution.

Moover handling system

The production flow is always guaranteed thanks to moover automation.

Once the operator has inserted the panel, the approach and insertion into the edge bander are completely automatic.

BarCode/QR Code reading

The reading system with the machine learning function allows continuous production without distinction among Batch 1 or mass production.

No need of downtime for changeover of panel size, edging thickness, ornamentation and glue type.

BN+ infeed device

The correct panel infeed is essential to comply with the shape and final size of the component.

The B+ automatic infeed device by belts with dynamic movement of dogs ensures the correct lengthwise insertion in the first edgebander and the crosswise insertion in the second edgebander

Suitable for panels already squared or to be sized and squared, it is equipped with overhead reference guide on right side of the gantry sizing system.

EdgeStore Manager

The automatic learning system via barcode or QRcode reader combines the program to be executed with the correct edge for extremely simple and fast management of the edge coil change. Thanks to the dedicated interface of the Maestro active edge software, all edge information (name, color, thickness, consumption, etc.) are always available on a single screen.

|

Machinable dimensions with lengthwise feeding

(length x width) (min/max)

|

mm | 250x130 / 3000x1200 |

|

Machinable dimensions with crosswise feeding

(length x width) (min/max)

|

mm | 180x250 / 1200x3000 |

| Operators | n° | 1 |

| Program change to Batch 1 (reading of unique code on panel by Bar Code / Qr Code) | - | YES |

| Possibility to size the panel | - | YES |

| Change of colour, thickness, edge protection film | - | YES |

| Panel dimension change | - | YES |

| Groove position and depth (in flexible mode) | - | YES |

| Glue dosage change | - | YES |

| Addition of a panel during Batch 1 machining | - | YES |

| Homogeneous panel management | - | YES |

| Panel re-machining | - | YES |

| Edge bander model | - | stefani one / stefani sb one |

Request information

Fill out the online form to be contacted by a salesperson

Thank you Your message has been sent.

Error! Something wrong has happened