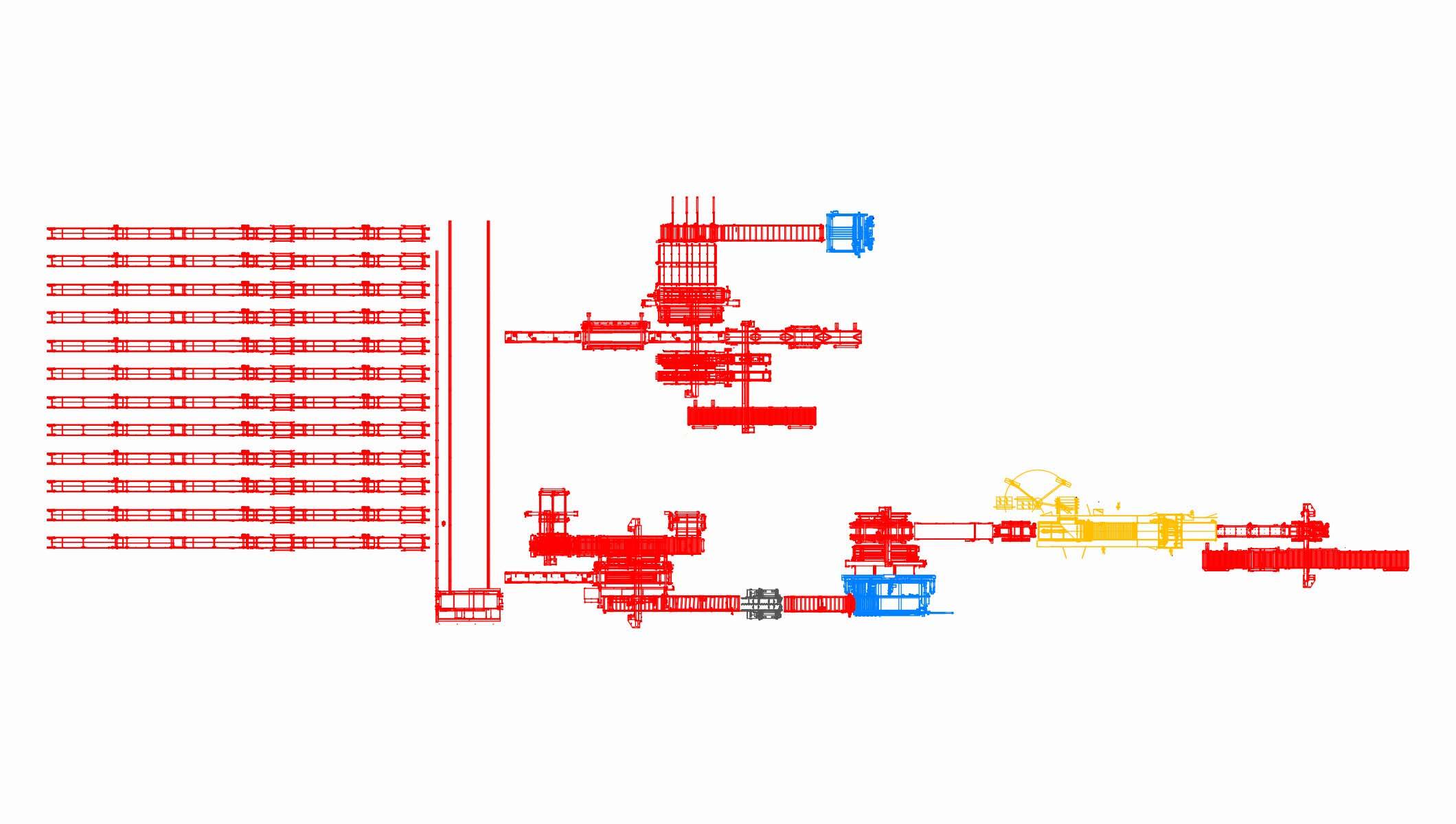

Post - processing line for insulation boards - Output 20 mt/min.

■ Automation systems ■ Profiling machines and double-end tenoners ■ Beam saws ■ Packaging

Complete line for cutting, squaring, curing, packaging, and stacking of phenolic resin boards.

Highlights

- Total integration: from the extrusion of the material to the production of the finished product packages through panel de-humidification.

- Complete production tracking: by the supervisor it is possible to monitor the status of the line in real time.

- High flexibility: it is possible to change the product thickness automatically and final size of the panels without interrupting the extrusion process.

- Reduced space thanks to the 'U' configuration of the system.

| Features | ||

| Panel size: | ||

| Min. dimensions of raw motherboard | mm | 4000x1220 |

| Max dimensions of raw motherboard | mm | 4800x1220 |

| Min thickness | mm | 25 |

| Max thickness | mm | 200 |

| Max weight | kg | 42 |

| Max density | KG/cubic mt | 35 |

| Operators | n. | 6 |

| Required space | m2 | ~ 850 |

| Production | ||

| Phenolic resin board covered wirh flexible facings |

Request information

Fill out the online form to be contacted by a salesperson

Thank you Your message has been sent.

Error! Something wrong has happened