When is glass UNsuitable for automation in glass fabrication plants?

30 Mar 2023In glass fabrication plants, moving glass from racks to processing machines is necessary, even if this work has low added value, it can be dangerous if the glass breaks and it can sometimes be a weary job.

So, when should automation be avoided for glass movement?

Glass loading and unloading automation is NOT recommended when the production process involves small daily batches (around ten) of lightweight glass pieces (weighing under 25 kg). In these cases, operators can safely manage multiple machines within the plant.

In all other cases, however, yes!

However, for example for larger or heavier glass pieces, a customized CMS solution for loading/unloading glass pieces from production lines is financially more advantageous.

The automatic glass loading and unloading systems allow you to handle different sizes and shapes of glass even when they are “batch 1”, that is, when each piece is different from the next.

What is an example of glass that can be moved using automatic systems?

-

up to 250 kg in weight

-

up to 3300 mm x 2000 mm

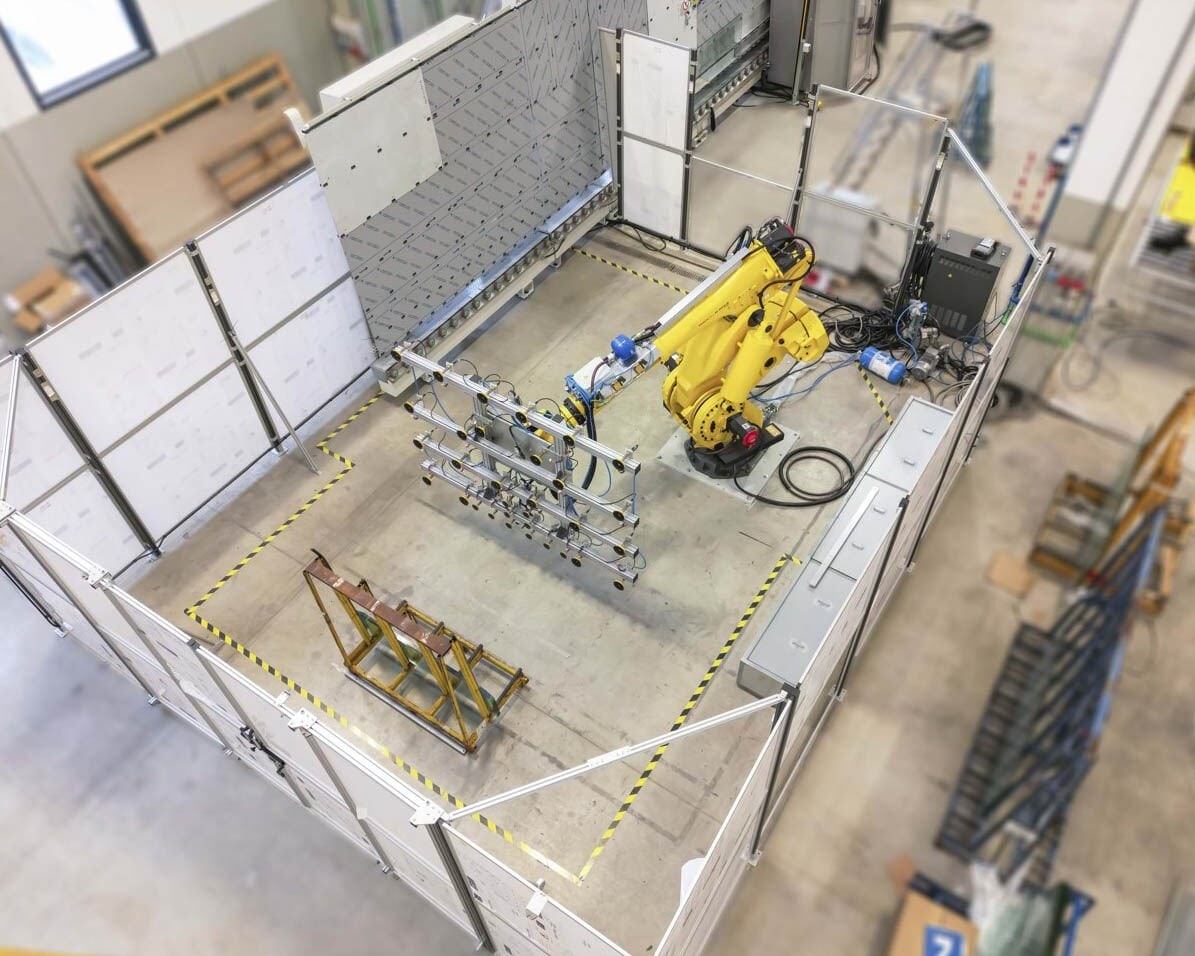

What is the CMS island for automatic loading of vertical lines made up of?

-

1 Articulated robot

-

1 EOAT (End of Arm Tool) designed for glass movement

-

1 Panel with software to manage the island

-

Safety devices

What is the CMS island for automatic unloading of vertical lines made up of?

-

1 Articulated robot

-

1 EOAT (End of Arm Tool) designed for glass movement

-

1 Panel with software to manage the island

-

Safety devices

-

1 Paper spreader

What is a paper spreader?

A paper spreader is an automatic device completely designed and developed by CMS that places strips of paper between glass pieces on racks.

This system allows the operators to focus on other tasks, without worrying about separating the glass and this helps the operator with positioning spacers on large pieces of glass that are hard to reach manually.