Marbrerie Retegui Bergez and CMS: the innovation of tradition

28 May 2024In the south of France, within easy reach of the border of Spain, you can find "Marbrerie Retegui Bergez", a family-run company of marble masons.

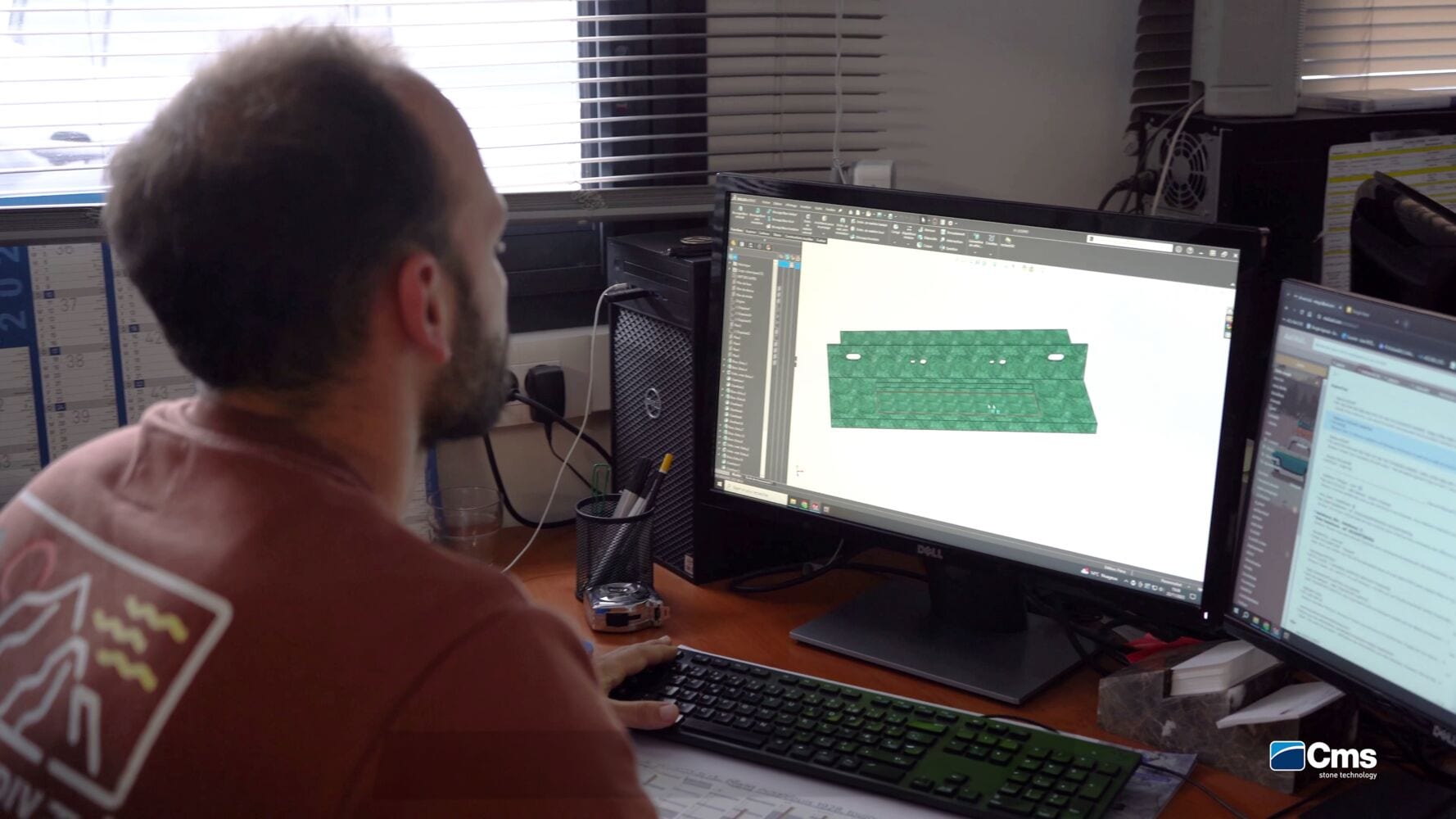

We are welcomed by Jean Retegui, responsible for measurements, drawings and coordinating production and installation activities.

He briefly tells us the history of the company, now run by him and his father. It was founded in 1939 by his great-grandfather and specializes mainly in the funeral sector. In 1999, his grandfather took over, and immediately wanted to bring technology and innovation to the company. These improvements opened up new possibilities in particularly demanding sectors such as bathroom and kitchen furniture, luxury products and cosmetics.

It is precisely the desire to add new technologies and embark on a path of innovation and growth that pushed Retegui to buy the first CMS machine in the 2000s, a brembana speed, starting a long-lasting collaboration that continues today.

The efficiency and reliability of CMS machines have become an essential mainstay for the company, so much so that it now boasts three models in its production department: a new brembana speed, a brembana maxima and a brembana kosmos.

The brembana speed is equipped with cutting-edge technology and has revolutionized production by eliminating the use of jigs and minimizing errors, while the brembana maxima has made it possible to reach new finishing standards, thus minimizing manual work.

But it is the brembana kosmos that has given Retegui the greatest satisfaction. Its integrated suction cups and tilting worktable mean that it offers operators safer and less invasive machining, while preserving the delicateness of the materials and guaranteeing impeccable results.

"Always being in contact with the same people", says Jean, "gives us a sense of security and the guarantee that our requests are always listened to and processed".

Thanks to the precision and versatility of CMS technologies, Retegui can offer his customers products of the highest quality to ensure they are satisfied, while dramatically reducing production times.