With Decore-ative Specialties, high quality extends coast to coast

Technologies for surface treatment

The US company has been manufacturing top quality and custom cabinet components for almost 60 years. Finishing is decisive in meeting the most challenging customers’ needs, this is the reason why they purchased the latest technologies from Superfici and SCM.

Founded in 1965, Decore-ative Specialties is a manufacturer providing custom cabinet components to the kitchen, bath, closet, garage, office, remodeling, refacing, healthcare, and multi-family housing industries.

Product offering includes RTA (ready-to-assemble) cabinets, doors, drawer fronts, drawer boxes, moldings, accessories, finishing, and hardware that are manufactured in wood, plywood, 3D laminate, and melamine.

Headquartered in Monrovia, California, they operate manufacturing facilities in Irwindale, California, and Monroe, North Carolina.

Decore-ative Specialties offer Solvent-Based finishing to meet every customer’s needs. “Our goal – as explained by Todd Shapiro, Vice President - is to bring the highest level of quality, service, and innovation to each option we offer as we come alongside cabinetmakers nationwide to make beautiful spaces for living and working. Our Solvent-Based finishing allows customers to order their products finished with paint, primer for painting, clear topcoat, or spray-to-color stains. After placing their Solvent-Based order, we can arrange to ship a COLORFIRMATION® sample block of the color we are producing. This provides the security customers expect when choosing a finish color”.

According to Decore-ative Specialties, technology innovation is strategic to guarantee efficient processes and high-quality products. This is the reason why they chose a Superfici finishing line including a sanding conveyor downdraft table, a panel cleaner, a panel pre-heat, a paper belt spray cabin and a U-Shaped dry line. The line also has a Superfici integrated three component mixing station. “This system works great!”, comments Todd. “This line is an improvement over hand spray for several reasons: coating is applied evenly on the face and edge of every part and is always dry as it exits the line, the quality of the enclosed system is better and guarantees less ‘trash’ in the finish, chemical mixing of the base and catalyst and thinners are consistent every time”. Automation is also appreciated: “Hard jobs are made easier: our machine operators are relieved from hard labor of hand spraying and material handling and are able to spend time looking at quality and inspecting parts”.

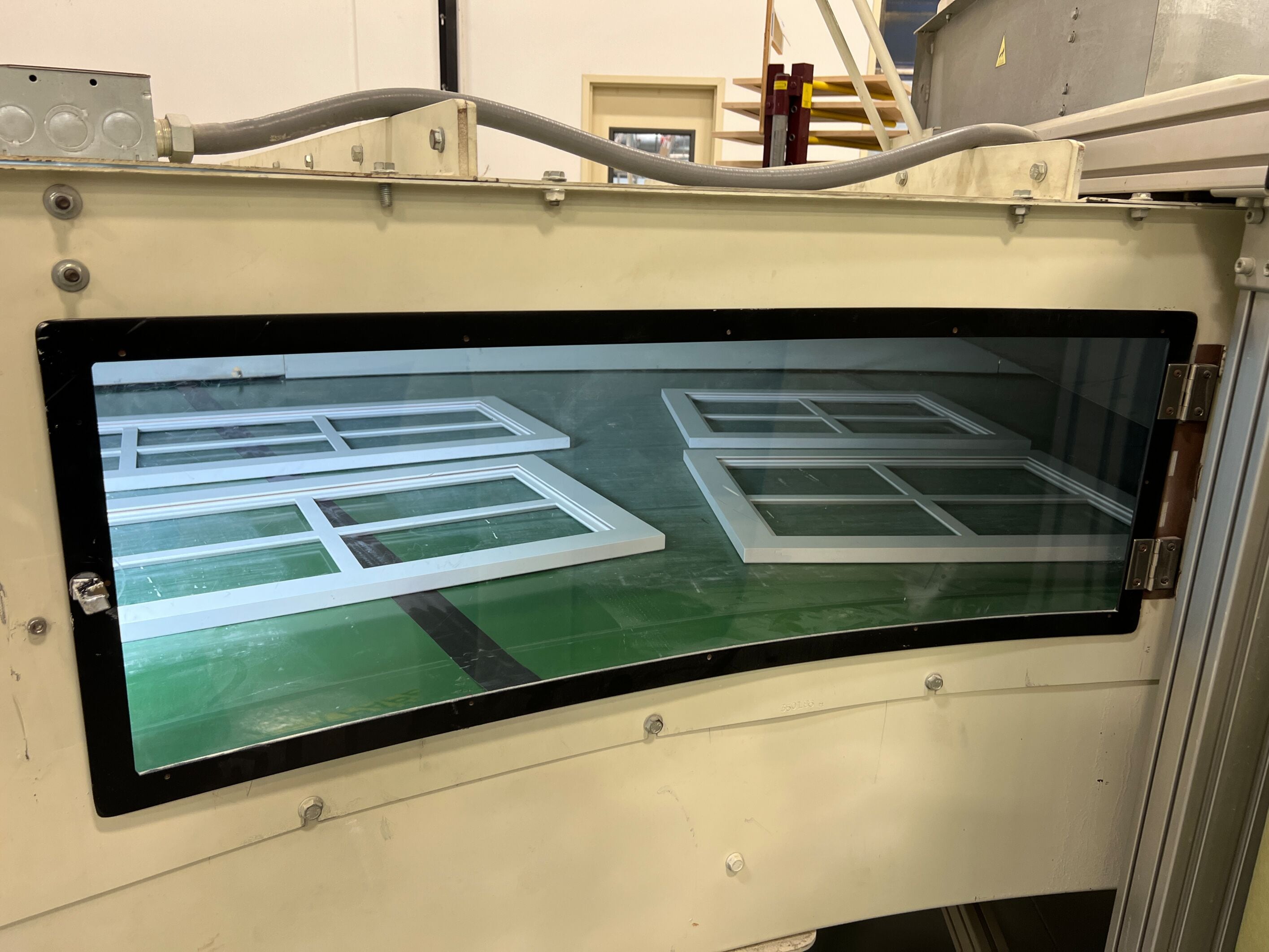

Decore-ative also has two sanding lines for doors and face frames production with several of SCM’s DMC sanders in each line. Almost all of them are the latest DMC system models.

Other DMC sanders are off the line, including an old planer machine that will also be replaced by a large DMC system.

“We have purchased multiple DMC sanding lines for both East and West Coast operations and one of the main decisions to purchase them is because of the new orbital sanders – adds Todd -. DMC sanders are unique to the industry. Cross grain sanding removal is critical to the US market, our customers expect the cross grain to be removed on both the face and back of the cabinet doors and for these reasons the DMC sanders are very effective.

The newer DMC models prove to be extremely reliable and easy to train new operators how to safely operate the equipment. Furthermore, the new lines all have the latest safety upgrades – both electronic and mechanical, including see-thru glass side doors and LED lighting. Both are a big improvement for sanding machines”.

According to Todd, Superfici and SCM are the best technology partners. “We choose to continue to do business with SCM and Superfici because our relationship with their Sales and Management team is great. People buy from people they like and trust and SCM and Superfici both have great people!”. That’s not all. Todd also comments: “SCM always has leading-edge technology for our industry and Spare Parts and Service are outstanding! Part fulfillment is consistently good too, even on older machines”.

The quality of after-sales technical support is a further highlight in the partnership with Superfici and SCM. “This is an area where we feel the entire SCM Group does a nice job. They always ‘take care of business’ and stay with us all the way to completion. They have a great team of experienced people that always help us to a solution!”.

With such a reliable partner at its side, Decore-ative Specialties looks forward with a future-proof vision. Digital transformation and Industry 4.0 are topics that the company is focused on. “We do have a newer line that is fully integrated with our manufacturing data. This allows the operator to scan a work order and the entire line of machines will set up specifically for an individual work order. We are also keeping an eye on the development of Industry 4.0 technologies. Although it’s still in its infancy stage, I believe this will grow and will be an important consideration for high technology equipment purchases. We see many long-term advantages for making the investment of cloud-based data for our machine centers, such as the improvement of preventative and predictive maintenance and the use of productivity dashboards to help us increase the efficiency of our internal processes”.

The “coast to coast” trip of Decore-ative Specialties continues in the name of innovation.

"We choose to continue to do business with SCM and Superfici because our relationship with their Sales and Management team is great. People buy from people they like and trust and SCM and Superfici both have great people!”

Todd Shapiro

Decore-ative Specialties

Fill out the online form to be contacted by a salesperson