nuCamp

Technologies for the nautical and car industries

Maximum comfort in a teardrop

The nuCamp campers and travel trailers combine good looks, high quality raw materials and innovative design. This North American company selected SCM for its wood processing and more specifically, a morbidelli p200 boring-milling and edgebanding centre capable of genuine “miracles”....

High quality technology, comfort and innovation. Even on the busiest roads, nuCamp campers and travel trailers can be spotted in an instant thanks to their refined design and unmistakeable teardrop shape. They are produced by the family run company of the same name in Sugarcreek, Ohio (also known by its historical name of Pleasant Valley Teardrop Trailers LLC), with 185 employees, and are aimed at the high end of the market mostly in the United States and Canada.

Manufactured in traditional hardwood, plywood and composite materials, these special vehicles need to meet precise requirements: high quality, lightness, intelligent use of space, practicality and eco-sustainability. The internal spaces of these “teardrops on the road” need to be optimised to make them striking and include all services and comforts on board that camper enthusiasts cannot live without while travelling. Reassurance, however, is also needed that it is agile in its movements while also being sturdy and stable. The raw materials, technologies adopted and investments into research and development, therefore, play a key role in creating the end product.

Almost the entire interior infrastructure is made of wood, including the stunning birch cabinetry and is produced “in house”, organising all the cutting, edging, assembly and finishing operations within the same production department. The only work that is outsourced are the dovetailed drawers and traditional doors with wooden frame that further characterise a range of vehicles.

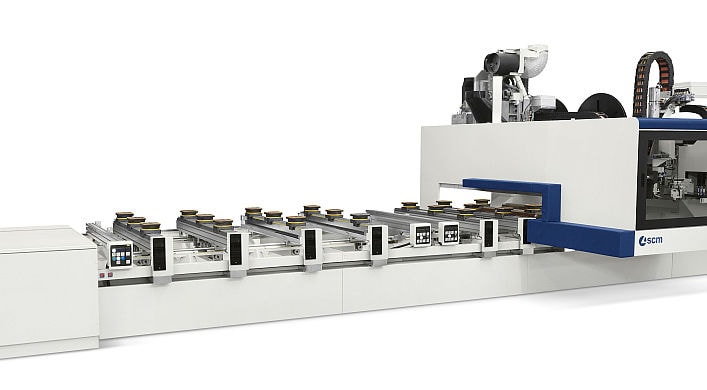

“The most important technologies for our wood processing department - they explain to us from the company - are the SCM machining centres morbidelli m400 for boring and milling and the morbidelli p200 boring-milling and edgebanding. We use Alphacam and SCM's Maestro software line in combination with these solutions which allow us to optimise and automate the flow and in particular, the edgebanding process. SCM’s advanced technologies help us simplify, automate and increase productivity, a key advantage in being able to compete successfully in a frenetic market like ours”

The words of a company that has always been ahead of the rest of the industry. Unlike the car industry, campers have not made any significant progress in recent years in implementing high tech solutions. This can depend a great deal on the fact that the camper is a luxury item and not a basic necessity like a car, and is forced to live with a more unstable market. The road to success, therefore, lies with innovation and nuCamp is sure of this.

The most recent purchase made from SCM was the morbidelli p200 machining centre, the same one that won an award at the IWF Atlanta Fair, with the Challengers Award for its exclusive HE-POD suction cup system patented by SCM to meet every milling, edgebanding and boring requirement. Indeed, this system makes this machining centre unique on the market: the HE-POD suction cups add the third dimension to the work table, allowing the perimeter work to be carried out without the need to move, thanks to the alternating lifting of the pieces.

“This machining centre - continue those from the North American company - solved a number of our problems and eliminated the difficulties encountered with hand processes including shaped profiles, always produced manually, with a table saw.

The main advantages achieved with the morbidelli machining centre is the possibility of providing the client with high quality production. “We also use PUR glue on all the lateral band parts, which is very resistant (up to 360 degrees Fahrenheit) and has an almost invisible glue line, guaranteeing a sleek, clean look”.

The nuCamp team decided to place its trust in SCM because their solutions “have a solid structure, are more reliable and require less maintenance - add those from the American company -. It was the best long-term investment we could ever make”.

We get the impression they are highly satisfied, not only with the type of technology purchased, but also the level of assistance received at the after-sales stage. “Any manufacturing company knows that faults are problems are inevitable. Based on our experience, we can guarantee that SCM has the best support team. SCM helped us avoid downtimes and quickly deal with certain problems. The support we initially received from Rob Howell and Phil Bryant was outstanding, and Arvid Estep has always been able to identify our needs. SCM is a guarantee for us”.

nuCamp - To Build the Exceptional

Fill out the online form to be contacted by a salesperson