CMS Active and Connect: HMI and IoT in the digital world

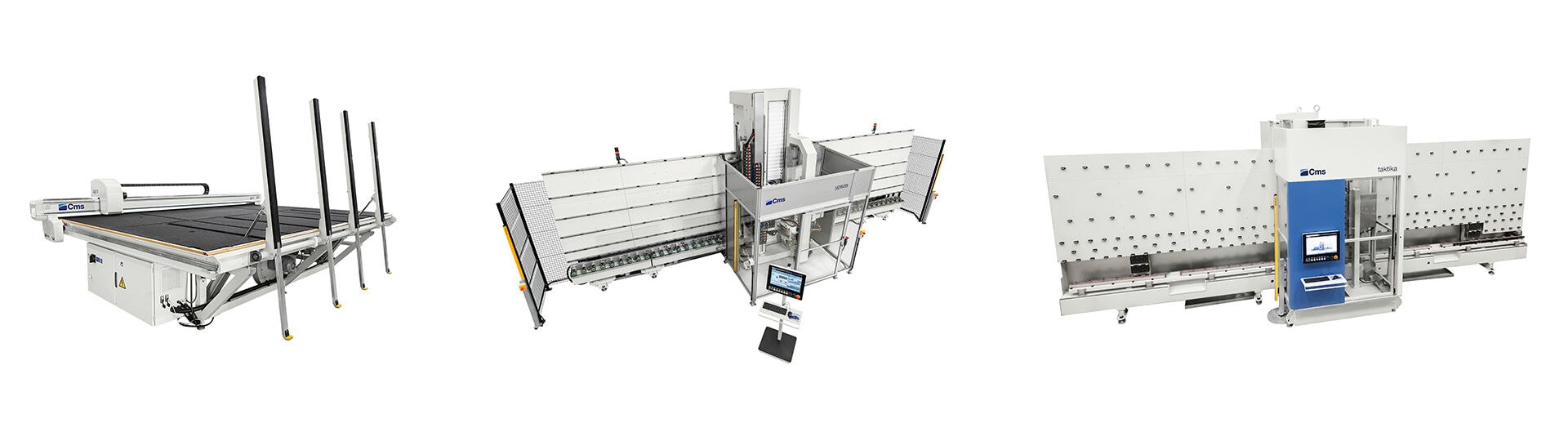

May 30, 2024CMS commitment towards constant growth in the digital field is concretely transformed into two latest generation solutions: CMS Active and CMS Connect, to optimize the operational efficiency and productivity of glass processing machines.

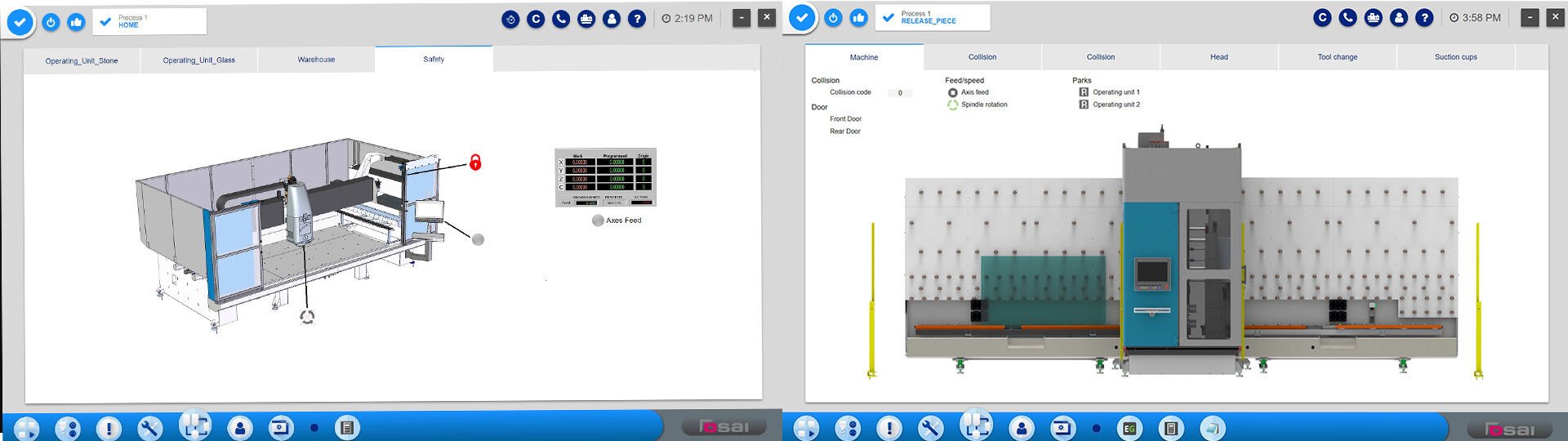

CMS Active is the new software interface specifically designed and optimized to make management of CMS work centres and cutting tables more intuitive, immediate and easier for the operator, who can have everything immediately under control.

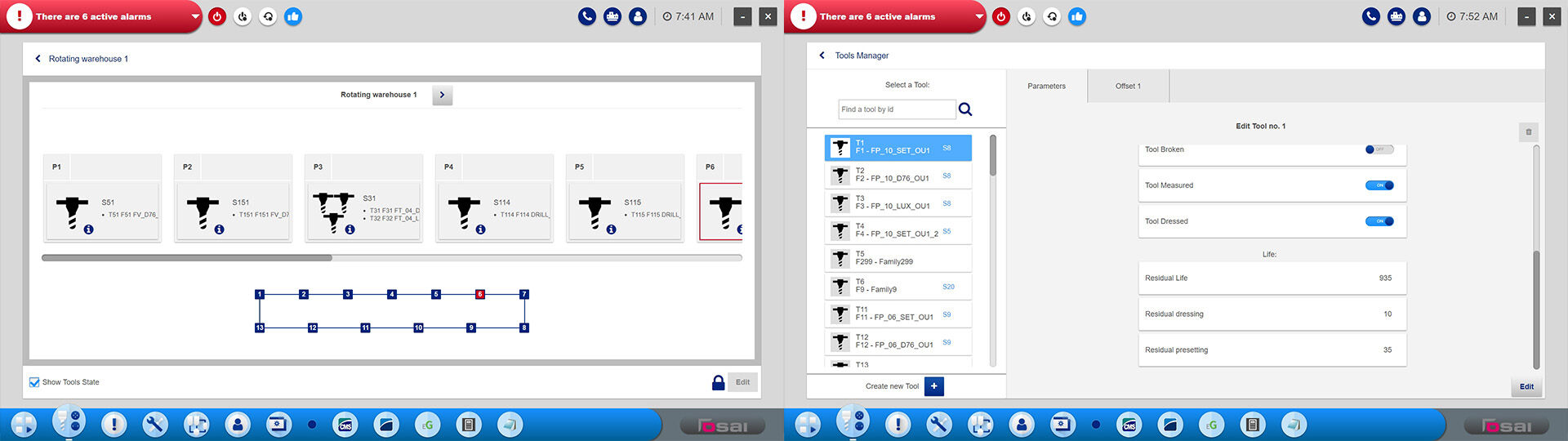

CMS Active is our completely re-designed HMI. The new interface has been designed and optimized to make management of CMS work-centers and cutting tables more intuitive and easier to navigate.

CMS Active simplifies tool management in work-centers and cutting tables, reducing the chance for user error and ensuring high quality finished products.

CMS Connect is the IoT platform active 24 hours a day, 7 days a week and on any device. It offers a wide array of functions and services to help improve the efficiency of CMS work centres and cutting tables for glass processing and constantly monitor their use.

CMS machining centers and cutting tables now come with a complimentary one-year subscription to CMS Connect at no cost.

CMS Connect displays, analyses and monitors all of the machine data in real time and then reports this data in various formats and views. This can then be used for continuos process improvement and maintenance monitoring.

CMS Connect includes three sections: Smart machine, Smart maintenance and Smart management.

SMART MACHINE

Continuous and detailed monitoring of the operation of the machine and analysis of the machine’s state.

SMART MAINTENANCE

Predictive maintenance with timed notifications for scheduling maintenance downtime based on the health status of the components.

SMART MANAGEMENT

Presentation of key KPIs of connected machines, to evaluate the availability, productivity and efficiency of the machines.

With CMS Active and CMS Connect, the future of production is within reach: more efficiency, control and safety for an increasingly digital industry.