IWF

22-25.08.2018 Atlanta, USA

SCM to bring frontline wood innovation to IWF 2018

Georgia World Congress Center, Atlanta | August 22-25 – Booths 6753, 6953, 7153, 7121

ROBOTIC CELL SEMINARS: ROBOTIC INTEGRATION FOR WOODWORKING TECHNOLOGIES

STAY AHEAD OF THE CURVE

MOVE BEYOND STAND-ALONE SOLUTIONS

Join SCM as we present robotic integration for woodworking technologies. Demonstrations will include real case scenarios with techniques used to streamline production processes. Learn the fundamentals of collaborative and industrial robotic integration and discover how to safely implement these concepts to drive productivity and profitability.

ROBOTIC NESTING CELL DEMONSTRATION

A robotic nesting cell and morbidelli n200 nesting cell will demonstrate full production cycles with automatic label placement, along with loading and unloading nested parts. Smart unloading of the nested parts using an industrial robot will feed the stefani kd edgebander and stack the finished parts. Using a mobile industrial robot, the material will be transported to the next station. Next, the doweling cell, composed of a collaborative robot and an Omal HBD 1300 OF, will drill and dowel the tops and bottoms of rails. At the end of the cell, the cabinets will be assembled, clamped, and fitted with doors and drawers.

THE SCM EQUIPMENT FINANCE ADVANTAGE

Since 1990, SCM Equipment Financing has remained the industry leader in helping customers acquire the equipment they need with the most flexible and competitive rates in the market.

- Up to $500,000 application-only approvals

- Principle only buyouts

- $500 documentation fee WAIVED

- Half payments fort the first 12 months

- Terms up to 84 months

- No advance payments

- Receive a gift card valued at $100 to $500

MAESTRO DIGITAL SYSTEMS

At the Atlanta trade show, SCM will present "Industry 4.0" applicable solutions. In the area dedicated to the “giant from Rimini”, the new digital systems conceived by SCM will take centre stage: products and services made possible by an increasingly widespread availability of data and their analysis, enabling quality control and qualitative assessment of production - from the techno-logical and IT development of the individual machines and their ability to operate in cells and cell systems.

SCM customers will be able to tour the Digital Hub, an area dedicated to presentations and sharing where the latest generation, multi-function, wide-screen and multi-touch operator control panel (eye-M) will play a leading role; where another highlight will be the innova-tive remote assistance and maintenance system with augmented reality glasses (Maestro smartech), as well as the powerful Maestro suite, a comprehensive software suite for all processing types and methods, not to mention the Virtual Reality 3D Inte-grated Cells simulation system (Maestro xplore) and other digital solutions that im-prove human-machine interaction, simplifying and speeding up production processes more and more.

At IWF SCM will present Maestro connect, the highly innovative "IoT" (Internet of Things) tools platform, enabling data retrieval from the machines for later analysis.

This is at the heart of the "smart factory" concept, which is simply a system that is able to monitor and optimise production processes so as to achieve predictive maintenance, which allows you to anticipate any possible need for extraordinary maintenance, thus avoiding potential downtimes.

Among these innovations, Maestro smartech stands out as the revolutionary remote assistance and maintenance system which employs augmented reality glasses: for users, it's just like having an SCM technician always at their side as they experiment with wearable technology.

Among the applications designed to work on a customer-interactive demo basis are: Maestro 3D, SCM's user-friendly, top performance solution for designing and programming 3D items, Maestro cut and ottimo cut for advanced cutting optimisation and management, Maestro watch, the production line supervisor, Maestro pro-edge, for linear edging programming and supervision, and Maestro beam & wall for the designing and programming of beams and walls.

A simulation system for integrated cells and systems based on the use of the Oculus 3D virtual reality viewer, ensuring an immersive sensory experience of SCM solutions designed for integrated production

THE MOST ADVANCED TECHNOLOGIES FOR CUSTOMISED AND INTEGRATED PRODUCTION

In an innovative and multimedia exhibition space at IWF, SCM will demonstrate new solutions for all industrial production processes, from furniture manufacturing to the nautical sector, from windows and doors to timber construction, and the most reliable wood-working machinery.

For all types of processing and for any production requirement, SCM technology represents a tangible application of "Industry 4.0" concepts and those of "mass customisation", and aims to satisfy the individual needs of customers, while conserving the benefits of industrial production.

SCM’s technological innovations will embrace the entire range of solutions on show for the sector: from machining centres for panel drilling to machining centres for solid wood and the timber construction industry, from edge banders and sizing edge banders to beam saws, from sanding to surface finishing, from assembly and packaging to presses, from the specific solutions for doors and windows to those for the squaring-tenoning and profiling, automation and top-level automatic handling, without neglecting the widest and most sought-after collection of machines for artisan carpentry.

Solid-Wood Machining Centres and Technology

In the field of solid wood machining and technologies, SCM offers a selection of possible applications for the production of windows, doors, stairs, chairs, design creations and furnishing accessories. The Accord range will be prominently featured at the Atlanta show: accord 42 fx will be joined by the highly flexible machining centre accord 50 fxm, for the processing of complex, large-sized items and for multiple fields of use, and by accord wd, the integrated cell for door and window manufacturing offering the same operation flexibility as a stand-alone machine.

The focus will also be on superset nt 32, the moulding machine enabling endless applications, and the balestrini line of compact tenoning/mortising machines pico md3 and pico om for special joints, as well as on the 5 axis, high precision power machining centre, in line with the increasingly demanding and varied requirements of the woodworking industry.

Squaring

Among the new products at IWF, the squaring machine p40 by celaschi, able to machine both solid wood and panels, and settable to machine joining grooves and J-Shape profiles and to perform straight or inclined machining. A fully electronic machine, it is equipped with latest generation electronic control and comes with the Maestro square software which makes it a 4.0 machine in all respects.

Panel Machining and Drilling Centres

Among the panel machining centres, in addition to the most eagerly awaited new design at IWF, morbidelli m220, the morbidelli p200 drilling, milling and edging machining centre will also be standing out for its innovative edge-banding unit, which can process up to 80 mm thick panels, and for its exclusive HE-POD suction cups, making the most of the machining centre potential thanks to alternate workpiece lifting.

Limitless cutting with Maestro Cut

Among SCM cutting options, gabbiani g 3/gt 3 165 is the latest addition to the already well known gabbiani g 3 / gt 3 series designed to meet all the needs of companies that need to machine medium to large batches in a continuously evolving market. Thanks to the Maestro cut software, the new operator interface has been designed according to "4.0 industry" principles and is now fully integrated in the "easy & responsive" production system.

Fast and high-quality edge-banding

As for edge-banding, SCM presents new devices starting from the olimpic range: its new range of Fastback panel return systems that increases the production efficiency of the stand-alone edge-banding machine, up to 20-30% with a single machine operator and an air-cushion bench positioned infeed which considerably helps the operator when processing panels of great dimensions.

A model to be pointed out is olimpic k 560, the reference machine for small woodworking companies, which further increases its performances thanks to the possibility to machine solid wood edges up to 12 mm thickness, for a greater versatility of use.

Highlights for SCM edgebanding machines also the new AirFusion+ device, which helps the hot-air/zero glue line application increase productivity by +10% and cut start-up times by 50%. Among the machines on display, which include with the new HMI "eye-M" with 21.5" multitouch display featuring 3D preview of the machined panel, there is stefani xd, the most up-to-date application of the wealth of expertise acquired by SCM in the field of industrial edge-banding. Among its added values are the generation E spindles, designed to provide a solid balance between lightweight machining and new rigidity standards.

New goals for sanding

The showcased sanding solutions are also expected to be of great interest for the furniture industry and contractors who need solutions suitable for intensive use and able to ensure striking and highly customisable results: from dmc system t4, able to achieve, thanks to its internal cross-belt unit and planetary unit, excellent finishes on both unpainted and painted panels, to dmc system t5 equipped with two carver units and a saw cutting unit, particularly suitable for obtaining effects such as carving, band saw cutting or structured effects.

Pressing: an extended range to cater for all market sectors

SCM also intends to further strengthen its role as a pressing segment player with an even wider range of solutions, able to respond to all market requirements. In addition to the manual sergiani gs and automatic sergiani ga-a hot processing presses, designed to meet a variety of customer needs, particularly in the field of panel and door machining, SCM now plans to expand its presence in the pressing segment with pf cold-working presses, gsl-a and gsl-k presses for strip panels, 3d form for membranes, vb vacuum boxes and various line solutions featuring simultaneous loading single and multi-compartment automatic presses.

Optimal waste-free finishing with Maestro

The SCM range is completed by the Surface finishing solutions: from Maestro, anthropomorphic robot for the quality paint finishing of doors and windows, to the Magnum sprayer, with its integrated user-friendly, intuitive software able to manage parameters, functions, diagnostics and recipes.

Woodworking machines: an "Invincible" story

Last but not least, the evergreen joinery machines, world-leading top class designs combining unique performance and continuous innovation. These features are confirmed by the complete range of solutions displayed at the fair, and most remarkably, by "L'invincibile" range with its upgraded design and technological features, an absolute market benchmark in terms of precision, reliability and safety. The dual tilt introduced in the circular saws si x of the L'invincibile range is now extended to the smaller "minimax" version with the introduction of the minimax si x model with +/-46° tilting blade and programmable motor-driven movement. At IWF, the focus will also be on the combined edge rounder-trimmer unit for edge-banding machines - the ideal one-stop machine for facing and trimming the front and rear ends of panels and at the same time, rounding the front and back edges. The new VF extractors are innovative technology, clean air filters that complete the widest range of woodworking machinery on the market. Low-noise and efficient, they are ideal for any work environment.

PRODUCT HIGHLIGHTS

CNC MACHINING CENTERS

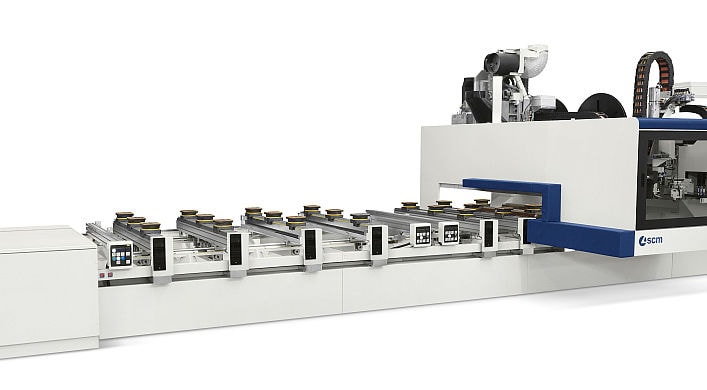

morbidelli m600/800f

CNC Nesting Machining Centres for routing and drillingModular machining centres equipped with multi-function aluminium work table, able to guarantee high quality standards. Performance without comparison with the mobile gantry structure and easy programming of all production process by means of Maestro...

morbidelli p200

CNC Machining Centres for drilling, routing and edgebandingUniversal machining centre designed to satisfy any drilling, routing and edgebanding requirement. Just few clicks to design and manufacture pieces of any shape and to easily apply several typologies of edge. Unique on the market in having an...

EDGEBANDERS

stefani kd

Single-sided automatic edge bandersContinuous and versatile solutions for quality machining are the distinctive features of stefani kd. All you would expect from an edge banding machine: the use of EVA and Polyurethane glue thanks to the SGP glue pot, machining units with electronic axes...

SOLID WOOD MACHINING CENTERS - ROUTER/MOULDER

ENGINEERING

PANEL SAW

SANDERS

dmc mb 90

Automatic sanding and calibrating machinesdmc mb 90 is the ideal solution for the finishing of routed MDF panels, assembled kitchen cabinet doors, doors and windows and similar profiled parts (picture frame strips, cableways, matchboardings, skirting boards). Parts can be rough or painted.

dmc eurosystem

Automatic sanding and calibrating machinesExcellent finishing results are obtained when machining raw and painted panels thanks to the wide range of units (Cross-Belt, Calibrating Roller, Sanding Roller, Super-Finisher) that come with the dmc eurosystem, and to its prescribed approach: a perfect...

dmc sd 70

Automatic sanding and calibrating machinesIts high level of versatility makes dmc sd 70 perfect for different types of machining. In the furniture sector (with veneered and painted panels) it excels in the provision of optimum level finishing thanks to the 2.620 mm sanding belt length and...