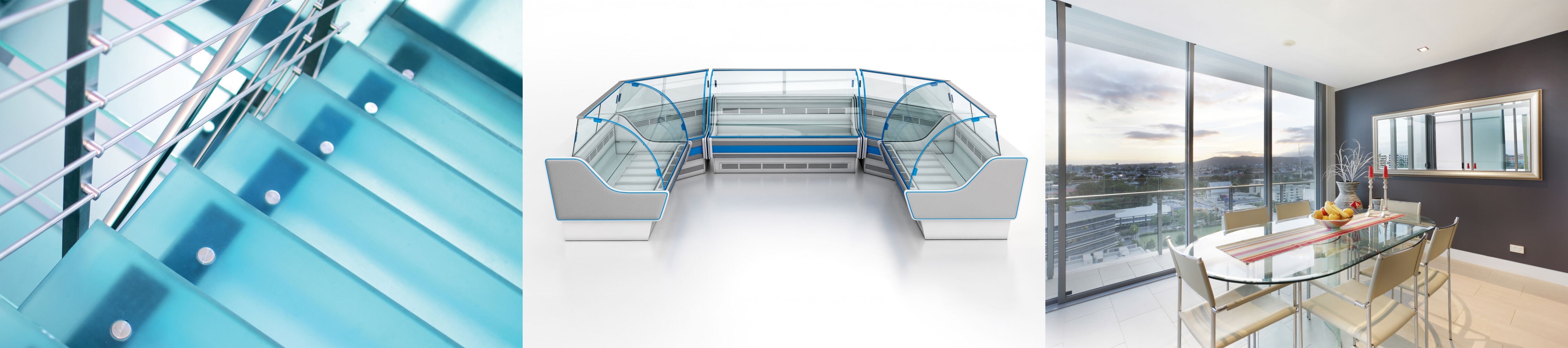

Discover the CMS horizontal machining centers, perfect for working your glass!

2024. dec. 16.CMS machining centers with 3 or 4 and 5 axes for the processing of flat glass, both thin and thick, float or laminated and bent glass.

CMS electa: is the 3- or 4-axis compact CNC machining center for the processing of flat glass, both thin and high thickness, float and laminated.

Application fields: Cooktop, Shower stall, Coffee table, Mirror

CMS gea: is the intermediate size 3- or 4-axis machining center for processing thin and thick flat glass, monolithic and laminated glass.

Table, Shower stall, Partition walls, Parapets

CMS speed twin: is the 3- or 4-axis machining center with two heads that allows to reduce cycle times. The machine is equipped with two spindles to simultaneously work two identical pieces. Also available with a turn table for loading and setup in masked time.

Steps, Display windows, Tables and windows

CMS maxima: is the 5-axis interpolated numerical control machining center with automatic tool change. It is extremely robust, and that makes it ideal for machining flat and curved glass. Thanks to the fifth axis, it can perform variable angle bevels.

Telescope lenses, Sports car windscreens, Yacht glazing, Large tables

Contact the experts of CMS Glass Technology today and find the best solution for your needs!