Scm Group UK @ W16

02-05.10.2016 Nec, Birmingham

3 unbeatable Scm Group Technologies as finalists at the Elements of Innovation Award

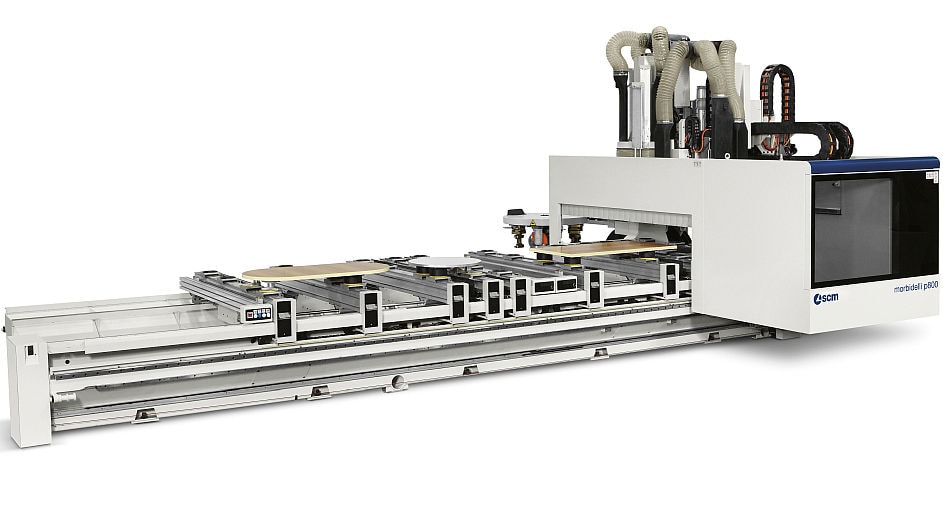

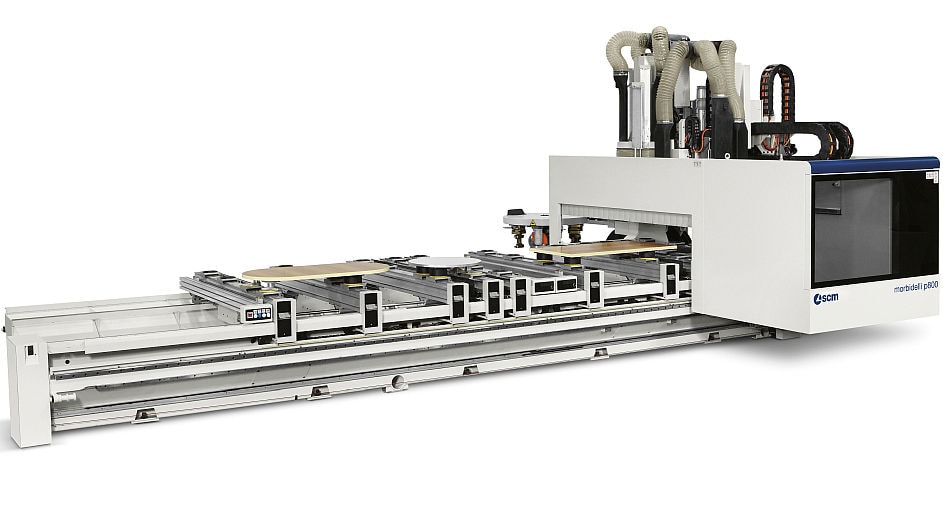

- Morbidelli Planet P800, the multifunction working centre for drilling, routing and edge banding

- Xylent cutterblock

- SGP Smart Glue Pot, for outstanding finish quality

Join us

Attendees will enjoy an interactive exhibition space with over 7,000 square feet dedicated to the group's manufacturing technologies and advanced solutions. "Strong Reasons Why" will be the driving concept behind our focus on SCM Group’s strong values, which translate into tangible benefits for our customers and demonstrates our ability to offer industry professionals an extremely wide and complete range of woodworking products and solutions.

An impressive arrangement of SCM product lines will be featured and visitors will see first-hand our machines in action through live demonstrations, along with industry experts available to advise attendees on the most efficient and productive solutions to maximize performance.

Particular attention will be dedicated to SCM Group Maestro software, a complete suite of cutting edge programs designed to guarantee full usability of all machine functions and to help operators carry out complex jobs through a simple and intuitive process. Maestro software and other SCM Group software packages will be demonstrated by appointment on the machines being displayed on SCM Group stands and on 2 dedicated software stations in the reception area.

SOFTWARE SOLUTIONS BY SCM GROUP @ W16

Several innovations for increased usability and performance

Scm Group brings its software know-how to W16, introducing a complete suite of cutting edge programs designed to guarantee full usability of all machine functions and to help operators carry out complex operations through a simple and intuitive process. The focus at the show is on Xilog Maestro, a software suite for the widest range of numerical control machining centres on the market today, with several new features that have been introduced.

Specific programs dedicated to the software's diverse applications complete the software package. SCM Group's software is being presented with two software stations on SCM Group reception area, each focusing on a specific sector, and on the machines being demonstrated:

Dedicated software for panels

Maestro

CAD/CAM software for designing 3D objects on 5-axis machining centres. Used for the first time with the Mobidelli Cyflex hp boring machines to improve boring, while maintaining simplicity. This new feature helps the operator integrate use of the Cyflex boring machine with any other CNC machining centre in the group.

A Cyflex HP will be demonstrated with Maestro CAD/CAM on Stand D610.

Book your personal demo

Maestro Nest

An integrated module provides all the functionality necessary for nesting – from a single rectangular piece to the most varied and complex free-form shapes. A new module optimises the way material waste is managed, improving performance and productivity.

A Morbidelli Universal and SCM Pratix S will be demonstrated with Maestro Nesting on Stand D610 and E610 respectively.

Book your personal demo

Maestro Edge

This software module handles all processes related to routing, boring, edgebanding and edge finishing operations. Besides being fully integrated with the Maestro suite, the software's greatest strength is that the operator begins by telling the software “what to do” rather than “how to do it”. The software then generates the information needed and creates the finished product.

A Morbidelli Planet P800 will be demonstrated with Maestro Edge on Stand D510.

Book your personal demo

morbidelli p800

CNC Machining Centres for drilling, routing and edgebandingmorbidelli p800 is a machining centre for drilling, routing and edge treatment for the furniture industry, the perfect solution for “just in time” production and for making panels that are ready for assembly. morbidelli p800 allows all machining on a...

Maestro Cabinet

Is dedicated to the creation of home and office furniture. It focuses specifically on designing furniture and programming cabinet production step by step.

A SCM Tech Z1 Pro will be demonstrated with Maestro Cabinet on Stand D610.

Book your personal demo

Maestro 3D

Is a module for programming 3D objects on CNC machining centres transforming complex shapes into simple commands.

A SCM Accord 25 FX will be demonstrated with Maestro 3D on Stand D510.

Book your personal demo

Maestro App

A library of programming functions developed by SCM Group and readily available for the creation of all the individual parts necessary for doors, windows, stairs, furniture, and furnishings. Macros have evolved in this version responding to developments in market demand.

Maestro Label

A new feature that handles labelling panels, for a more automated and profitable nesting process.

Maestro ProView

This 3D simulator brings a 3D model of the machine to the office on a dedicated PLC. The software simulates the work that will be done in the production process: includes a rapid simulator, which speeds up the testing phase.

Dedicated software for housing

Maestro WD

Software that focuses specifically on planning and programming every single element for linear and arc-shaped windows, doors and shutters.

A SCM Accord 25 FX will be demonstrated with Maestro WD on Stand D510.

Book your personal demo

Maestro MSL Connector

Allows external software to interface with all SCM Group's machining centres, which makes machining strategies easier to manage. Maestro, Maestro 3D and Maestro ProView are also dedicated to housing.

Dedicated software for beams and walls

QuickLink

3D manufacturing software for wood structures. The intuitive interface combines easy data entry, rapid processing and simulation and elevated flexibility, thanks to the different machining strategies. Integrated with the new Nesting function for x-lam walls.

Dedicated software for panel sizing

Win Cut

Manages the sizing process on the machine in both the program creation and execution stages. An interface connected to the machine's PLC provides clear detailed graphics for the operator.

Ottimo Cut

Automatically creates optimal cutting plans with parameters that can be adapted to suit the user’s needs. The new release has been developed to:

- Reduce the time needed for average complexity calculations (up to a 200% reduction), which

makes for a more efficient set-up and planning process in production. - Reduce waste (up to 80% reduction), decreasing the cost of the finished product.

- Reduce the number of single cut plans (up to 10% reduction), hence improving productivity.

Dedicated software for automated processes

Watch

Supervision system for complex automated processes, designed to centralise and simplify line management. The system optimises production changes, reduces fitting times, programs all the machines involved in the process through an integrated, modular process and provides reports and advanced diagnostics. SCM is constantly working on this software and improving performance. This proprietary software allows for maximum performance of all integrated installations by SCM Group Engineering.

Watch Store

Lets you manage and keep track of the Flexstore automated warehouse in real time. The software is integrated with the operating, sizing and numeric control machines optimising the production process. Several new features make for an even more automated production process, making cutting edge warehouse management and supply chain strategies available to medium and small producers.

Dedicated software for edge-banding

E Touch

A powerful application that let's you program and supervise edge-banding machines through a surprisingly fast, intuitive system thanks to a 3D virtual preview and the “what to do” versus “how to do it” philosophy.

A Stefani Solution MD will be demonstrated with E-Touch on Stand E610.

Book your personal demo

Other products on show @ W16

morbidelli p800

CNC Machining Centres for drilling, routing and edgebandingmorbidelli p800 is a machining centre for drilling, routing and edge treatment for the furniture industry, the perfect solution for “just in time” production and for making panels that are ready for assembly. morbidelli p800 allows all machining on a...

windor nt1

Angular machining centres for windows and doorsAngular machining centre for windows and doors manufacturing. It is possible to perform all of the essential operations of end-cutting, tenoning, drilling-routing and profiling regardless of construction concept, joint and section type. The machine...

dmc sd 30

Automatic sanding and calibrating machinesIdeal for the craftsmen and the small woodworking companies. Solid wood calibrating and sanding and veneered panel sanding operations (also with honey-comb support), and also for any other sanding requirements. The availability of the electronic sectional...