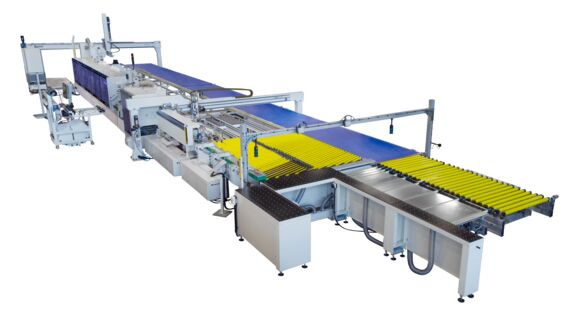

stefani sb one

(512) 931-1962

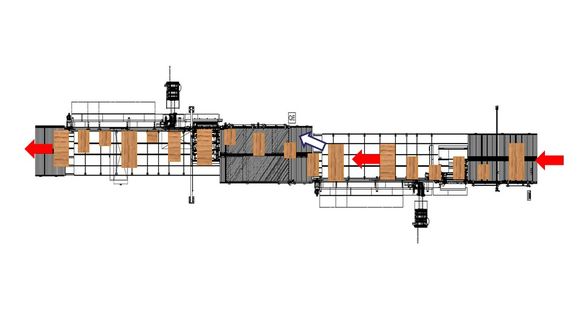

A single-sided squaring and edgebanding machine for the sequenced machining of panels that differ in terms of size, edgebanding strip and machining operations, with small batches or batch 1. Consisting of a single machining shoulder and specific insertion systems allowing the utmost variation and infeed speed of mixed panels.

"JUST-IN-TIME" MACHINING

stefani sb one guarantees short production times, with the possibility to also manage a single panel inserted at the last moment (and not included in the production list). This high degree of flexibility guarantees a return on the investment in a very short time.

CUSTOMISED PRODUCTIVITY

stefani sb one can be inserted in any edgebanding cell architecture (making it possible to achieve the production level planned by the customer) rather than respecting the space available on site.

FLEXIBLE TECHNOLOGY

Each working unit installed on stefani sb one is designed for flexibility (the quick change of the machining operation, the type of glue used, or the type of edgebanding strip). This is made possible by the supervision of the precise, fast software that evaluates every parameter and establishes the production accordingly.

| Productivity | cycles/min | from12 up to 18 |

| Feed speed for lengthwise processing | m/min | 40 |

| Feed speed for crosswise processing | m/min | 25 |

| Coil edge thickness | mm | 0.3-3 |

| Max strip thickness | mm | 1 |

| Max solid wood thickness | mm | 25 |

| Standard panel thickness | mm | 10 – 60 |

| PANEL DIMENSIONS WITH COIL EDGE | ||

| Lengthwise passing | ||

| Min/max panel length | mm | 320-3200 |

| Min/max panel width | mm | 130-1600 |

| Crosswise passing | ||

| Min/max panel length | mm | 120-1600 |

| Min/max panel width | mm | 260-3200 |

| Pneumatic system | MPa | 6 |

Fill out the online form to be contacted by a salesperson