Loferhome, more than just a furniture manufacturer: specialists in custom-design

Furniture Technologies

Together with its Engineering team, SCM has developed one of its most advanced solutions for the Spanish company's new plant: a "batch 1" flexible cell system for beam saw and edgebanding, plus stand-alone machines to complete the production process.

A long-standing tradition and experience in the production of furniture, combined with an increasingly more open approach to state-of-the-art technologies.

This combination lies at the root of Loferhome's success which, with its "Tua Casa" brand, stands out as one of the best-known and respected businesses on the Spanish and European markets. Adult and children's bedrooms, cupboards and wardrobes, bathrooms, living rooms and accessories: it offers a truly extensive range while continuing to guarantee maximum care with its finishings and design thanks to 3D simulation software.

At the helm of this outstanding business organisation is the López family. Active in the industry since the 1970s, it opened a new "record-sized" plant in 2018, in Albacete with: over 14,000 square metres of which 8,000 set aside for its production area with state-of-the-art “made in SCM” technological solutions.

What was the reason for this change? In order to guarantee a whole range of requirements such as process automation, production flexibility, quality machining and a significant reduction in delivery times which, in the case of “Tua Casa” products, can be as short as eight working days from the moment the order is confirmed. If we then consider that Loferhome creates custom-designed projects by covering the entire production process - from design to delivery - it is clear how high technology is the key factor for competing successfully.

A customer's need, SCM's answer

When the owner, José Luis López and the production Director, Martin Tebar contacted the SCM Spain team, which has been a partner to Spain's most advanced businesses in the furniture and wood-working industry for thirty years, they already had a clear idea of how the new factory should look. The most important aspect was that it had a sizing cell with two separate storages to ensure intelligent material handling: one for shaped panels and the other exclusively designated to managing off cuts, in order to avoid invalidating the effectiveness of the main storage. Indeed, manufacturing custom-designed products, the company needs to keep a vast range of materials, colours, thicknesses and finishings in mind, and all this risks generating a huge amount of scraps. So, avoiding waste and reducing production costs was of the utmost importance.

SCM had the upper hand over other competitors as it presented a state-of-the-art sizing cell that takes up only a part of the vast 8000 m2 plant overall, with a production capacity of more than 1,500 panels per shift: a "batch 1" flexible cell system for sizing and edgebanding, plus other stand-alone machines to complete the production process.

Sizing

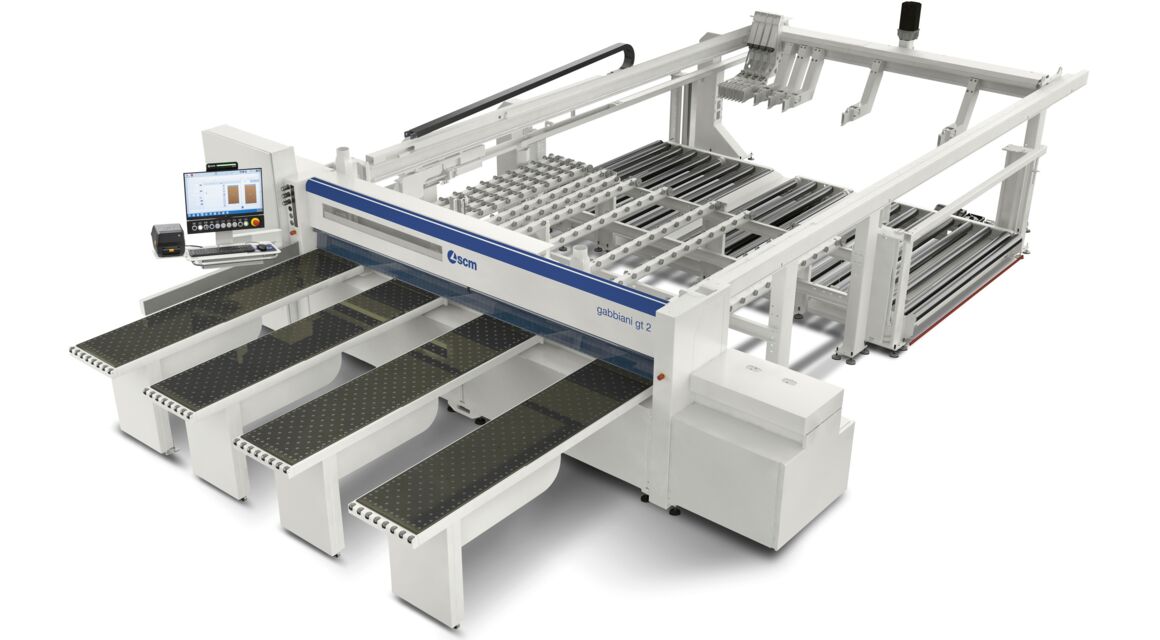

The cell consists of two automatic three-axis “flexstore el” storages, integrated with two “gabbiani g 2” and “gabbiani gt 2” sizing machines that both perform well in terms of speed and machining quality. There is also a machine for cutting the smallest off cuts and finest material: the "class si 400" sliding carriage sizing machine.

Not only does the system have a separate magazine for managing the off cuts that are automatically re-introduced but it is also highly versatile and can adapt to production needs. While the three sizing machines are equipped with specific functions, they can be interchanged depending on the amount of material being machined and the kind of re-usable off cuts. Indeed, in the case of small amounts, the "gabbiani gt3" specifically designed to machine off cuts, can be automatically powered by the main storage, so it can back up the panel sizing machine for shaped panels. In turn, the "si 400" can support the "gabbiani g 2" if there is an abundance of small sized off cuts.

Integration with the "Maestro active watch" cell supervisor software and the "Maestro store" storage is also key as they allow you to manage werehouses outside of the cell, used to store materials in other areas of the factory or the smaller rejects and thin panels.

Squaring and edgebanding

Flexibility is the keyword even for the square-edgebanding cell consisting of two "stefani sb one" single-sided edgebanders with automatic feed system for perfect panel sizing and squaring.

The strength of these solutions designed for big industry lies in their ability to work panels in sequence and just-in-time with different sizes, applied edge and machining, with small or pure "batch 1" batches. These machines are fully electronic and can achieve three radii automatically thanks to the Multiedge system. They have 24 roll edge storages, ensure a rapid and automatic change of glue colour and perform routing inside and outside the feed tracks.

One other key element of the cell is the "Maestro active watch" supervision software: thanks to the bar code on each panel, the software can match the right machining program and track and control all the process stages to each piece, as well as further control functions and production reporting.

The edgebanding of special and prototype pieces is done in another cell, made up of a “olimpic k 800” single-sided edgebanding machine with "Touch 7” control interface and panel return.

Stand-alone machines to complete the process

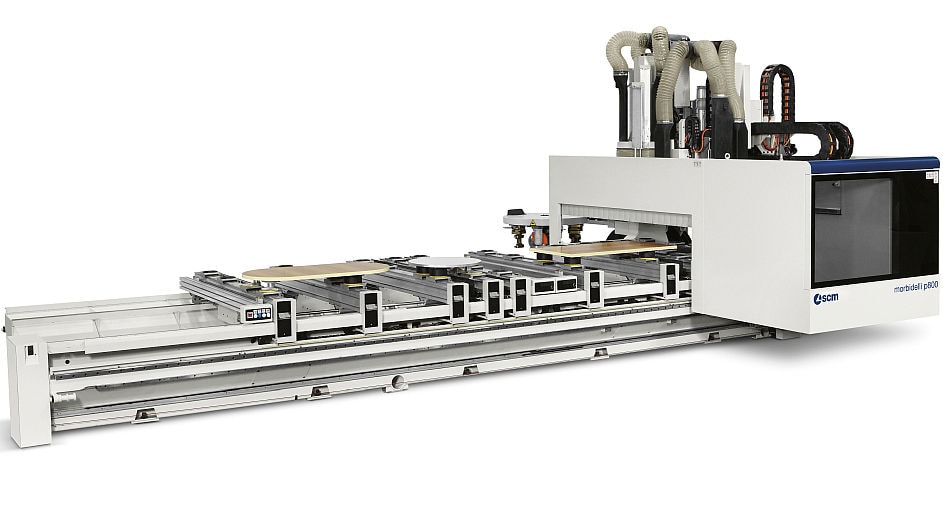

Loferhome selected two, state-of-the-art technological solutions from SCM: a “morbidelli p800” machining centre for drilling, routing and edgebanding, ideal for machining and producing "just in time" panels ready to be assembled, and a "morbidelli cx220", a compact CN drilling solution designed precisely for "batch 1".

The "morbidelli p800" which is also highly versatile, can be used in two ways: to apply the shaped edging to panels already squared or to drill, route and edge the unfinished panel. If the pieces being machined are mainly curved, the machining centre allows you to skip the passage in the squaring-edgebanding cell proving itself to be a real "wild card" in any factory. Some of its key advantages include its extremely fast set-up times thanks to the Matic automatic table with suction cups and bars that move automatically and simultaneously with anti-collision check.

In order to machine special panels and prototypes, the drilling is done with the “morbidelli cx220”, whose work table allows you to drill even delicate surfaces with excellent finished results. The new, shaped hold-down grippers mean that panels can be machined even in positions inside the grippers, greatly reducing cycle times and optimising workpiece clamping.

The flexible cell system designed and developed by SCM for Loferhome is an example of how a factory can be increasingly more versatile, adapting to changing production needs and those of the market. All this with maximum process optimisation, and a considerable reduction in costs and energy consumption.

Loferhome

Fill out the online form to be contacted by a salesperson