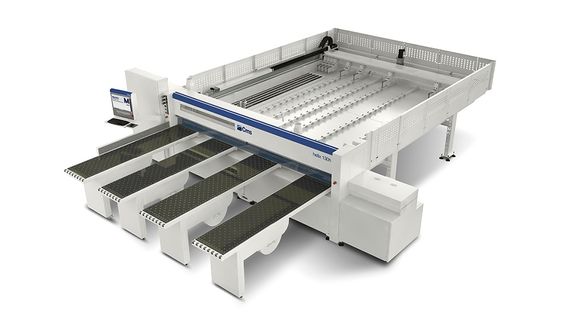

helix 90m / 110m

(512) 931-1962

Automatic beam saws for plastic materials processing

The best technological solution for the cutting of plastic materials in terms of parts quality and processing speed. It is equipped with a number of devices resulting from SCM's extensive experience in advanced materials sizing to satisfy any specific demand coming from companies processing plastics, acrylics and synthetic panels. Improved cut quality and processing speed are ensured by the adjustment of the blade peripheral speed, the optimized blade height, the main blade cooling and lubrication devices.

- Single-blade beam saw specifically designed for cutting plastic materials. Capable of meeting all the specific needs of companies that process plastic, acrylic and synthetic panels.

- Direct control of specific cutting parameters for maximum flexibility in cutting plastic materials. Directly available from control board: blade speed adjustment, optimized blade ascent, main blade cooling and tool lubrication.

- Selective air curtain work surfaces dedicated to plastic materials. Capable of ensuring excellent sliding of the sheets, only where needed. A substantial help to the operator in the management of semi-finished sheets. Less than 9% of time in sheet management.

TAILOR MADE

Single-blade beam saw specifically designed for cutting plastic materials. Capable of meeting all the specific needs of companies that process plastic, acrylic and synthetic panels.

MAXIMUM FLEXIBILITY IN CUTTING OPERATIONS

Direct control of specific cutting parameters for maximum flexibility in cutting plastic materials. Directly available from control board: blade speed adjustment, optimized blade ascent, main blade cooling and tool lubrication.

| Technical specifications | helix 90m | helix 110m | |

| Cutting dimensions | mm | 3200x2100 3200x3200 3800x3200 3800x3800 4500x3200 4500x4300 |

3200x2100 3200x3200 3800x3200 3800x3800 4500x3200 4500x4300 |

| Blade projection | mm | 95 | 115 |

| Main blade / engraver blade diameter | mm | 380/200 | 400/200 |

| Maximum blade carriage speed | m/min | 135 | 135 |

| Max plunger speed | m/min | 70 | 70 |

| Blade motor power c/inverter (optional compulsory) | kW | 11, 15, 18 | 11, 15, 18 |

| Engraver motor power | kW | 1,8 | 1,8 |

| Engraver rotation speed (50 Hz) | rpm | 4500 | 4500 |

| Blade rotation speed c/Inverter | rpm | 1.200/3.800 | 1.200/3.800 |

| Number of double-claw collets | std | 7 | 8 |

Fill out the online form to be contacted by a salesperson