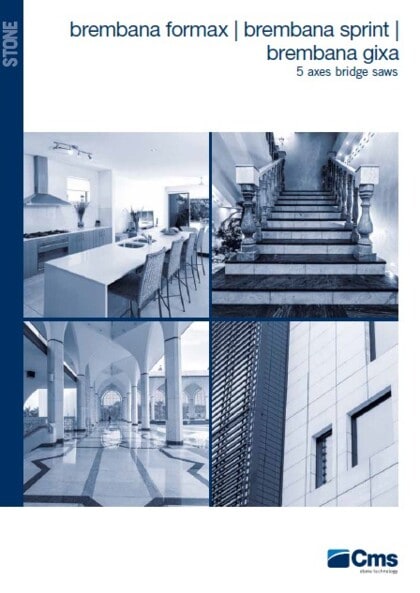

brembana gixa

(512) 931-1962

Large sized 5-axis CNC bridge saw

Numerically Controlled 5 interpolated-axis bridge saw equipped with tilting head and fixed table to carry out any type of machining, cutting (straight or shaped, vertical or inclined), 3D profiling and milling operations, on slabs and stone blocks.

This machine can work one shot or step by step to shape marble, granite, composite stone, and ceramic pieces.

The 4.250 mm stroke of the bridge guarantees easy machining of large sized slabs or stone blocks.

Its extraordinary stability allows to reach a Z-Stroke of 1.400 mm with disks with a diameter up to 1.200 mm; representing industry leading features.

UNRIVALLED MECHANICS

Open frame version, to install on concrete or carpentry shoulders guarateeing stability and rigidity to accomplish the most difficult processing and to ensure long longevity.

MOTION ACCURACY

As a guarantee of quality all movements are powered by brushless motors coupled with a precision reduction gear and transmitted through a rectified and tempered guides and ball bearings.

LIMITLESS TECHNOLOGY

The machine can be equipped with a powerful ISO 50 electrospindle which, together with the 5 interpolated axes, transform the machine into a modern and complete 5-axis machining center.

| x axis stroke | 4250 mm / 167 in |

| y axis stroke | 3000 ÷ 7000 mm / 118 ÷ 276 in |

| Z axis stroke | 900 ÷ 1400 mm / 35 ÷ 55 in |

| disk diameter | 400 ÷ 1200 mm / 16 ÷ 47 in |

| motor | 25,5 kW / 34 HP - 28,5 kW / 38 HP - 31,2 kW / 42 HP |

| motor revolution | 0÷5000 rpm (可选 0÷6000 rpm) |

| maximum working thickness (with 90° disk Ø 1200 mm) | 440 mm / 17 in |

| minimum working thickness (with 45° DISK Ø 1200 mm) | 315 mm / 12 in |

| head revolution (4th axis) | ± 270° (540°) |

| head inclination (5th axis) | +8° -90° |

| workbench dimensions | 4200x2500 mm / 165x98 in* |

| minimum space required for installation | 7700x5360x4430 mm / 303x211x74 in |

* = Bigger sizes available on request

Fill out the online form to be contacted by a salesperson