brembana electa

(512) 931-1962

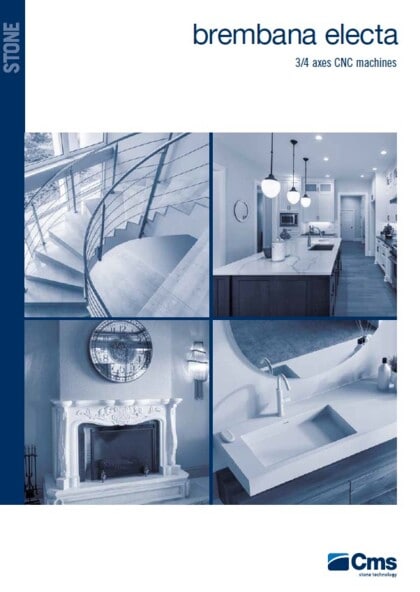

Brembana electa is a CNC machining center with 3/4 interpolated axes for machining slabs and blocks of marble, granite, synthetic stone and ceramics. It can quickly and accurately perform any type of edge contouring (coarse or smooth), milling, drilling, countersinking, pocketing, bas-reliefs and lettering.

The monobloc structure and full integration of guards, sliding doors, water collection tanks, systems and the electrical cabinet make electa the most compact machining center and ensure the best workpiece/machine size ratio of the cms stone technology range.

The high inertia and thickness of the Metal Synthetic Technology (MST) worktable, introduced to replace the conventional aluminum worktable, dampens vibrations, helping to improve the surface finish and general quality of the machining process.

KEY BUYER BENEFITS

- Productivity: the highest in its category thanks to axis movements at up to 72m/min.

- +15% work area: more space for your projects compared to the average on the market.

- Uncompromising finishes: the heavy monobloc structure dampens vibrations to achieve the best results in all machining processes.

The rotary C axis (4th axis) with a fast speed of 9000°/min can accommodate angular transmissions with continuous 360° rotation.

Brembana electa has an external 580 L water recovery tank and another tank for the water that the liquid ring vacuum pump uses to dissipate heat and deposit any solid particulate. The tanks are located below the base to minimize the overall footprint of the machining center.

Thickness probe to acquire the actual thickness of the slab to be machined, to ensure a perfect finished workpiece.

| X-AXIS STROKE - SPEED | 3450 mm | 136 in - 72m/min |

| Y-AXIS STROKE - SPEED | 1800 mm | 71 in - 72m/min |

| Z-AXIS STROKE - SPEED | 350 mm | 14 in - 15m/min |

| ROTARY AXIS (OPTIONAL) | C = 360° continuous |

| TOOL CHANGE STATIONS | 13 + 13 |

| ELECTROSPINDLE POWER ROTATION CONNECTION TORQUE |

11,5 KW | 15 HP 0 ÷ 15000 rpm ISO 40 18.5 Nm at 6000 rpm |

| ELECTRICAL CABINET | Built into the base |

| WEIGHT | 4600 kg | 10.100 lb |

| MINIMUM INSTALLATION SPACE | 6100 x 2950 x 2600 mm | 240 x 116 x 102 in |

Fill out the online form to be contacted by a salesperson