Diesse Arredamenti

Technologies for the nautical and car industries

Diesse Arredamenti, luxury on the waves

A continually developing company that specialises in exclusive interiors for luxury boats, and was brave enough to change production mentality, face up to the new digital challenges and renew its production lines with SCM

It is when you hit rough seas that a company like Diesse Arredamenti, experts in the production of interiors for luxury yachts and mega yachts since 1990, manages to get the best out of its fleet to keep on course towards success and innovation. Indeed, if we take a look at the history of this industrial organisation in Romagna, responsible for the production of customised furnishings for the most prestigious brands in the nautical industry, it doesn't take long to realise that some of the most difficult moments over the last few decades were followed by a dramatic change of direction for Paolo Ravaglioli, owner and sole director of Diesse Arredamenti, and his team.

With around one hundred employees, a turnover of 20 million and a new 11 thousand square metre headquarters opened in 2020 at the height of the pandemic, Diesse Arredamenti stands out from the crowd for its advanced production processes, aimed at achieving maximum efficiency, flexibility and quality when creating exclusive solutions, no matter what kind of yacht it is.

Each project is followed right up to the final assembly stage on board with expert professionalism in each department: the technical department in close collaboration with the design, production and quality control department. All done with the aid of advanced logistics and a MES system that guarantees full tracking of the parts and machining work and optimaistion of times and performances.

A story in continuous development

It was 2009, in the midst of the global financial crisis, that Ravaglioli chose to change course. He changed the company's production outlook, establishing new priorities, focusing on a more customised production, and opted for an even more aggressive investment in technological and digital innovation. While holding firmly to his passion for artisan craftsmanship and manual skills, at the heart of the company, Ravaglioli strengthened the technical department, acquired advanced software, including programs for three-dimensional machining, and purchased state-of-the-art numeric-controlled machinery.

Another important change came about in 2011, when the Italian economy was further hit by the aftermath of the global financial crisis of 2008. At that time, Diesse Arredamenti Spa was part of the Ferretti Group, a global nautical giant in Forlì. Ravaglioli decided to buy out all the Limited company's shares and take full control. As a result, the company broke away from a global benchmark in the luxury yacht industry, to embark on a new journey that would lead it to adopt new growth and development strategies and conquer new market sectors and important clients, while continuing to maintain fruitful relations with the Ferretti Group.

Brave choices that have continued over the last year, marked by the Covid-19 health emergency, with the transfer of all its offices and departments from three existing headquarters to a new state-of-the-art production and logistics centre.

New efficiency and production objectives with SCM

"Our industry is continually developing from a design and technological evolution point of view - explains Ravaglioli -. Our customers look for perfection, precision, as well as fast manufacturing and delivery times, and this is why the use of the most advanced technologies is essential".

Evolving becomes a priority because the market is continually and rapidly changing. It is essential to adopt organised industrial processes, as well as improve efficiency and productivity. As a result, the choice of a technological partner is not random. "Our relationship with SCM started with the expansion of our company - continues Ravaglioli-. Over time, the need for precise, fast and advanced machinery grew. We felt the need for a reliable partner and we found this in SCM".

The Diesse Arredamenti production plant boasts different technological solutions from the Rimini-based Group, including numeric control machining centres, sanding machines and joinery machines. Working at some of these state-of-the-art technologies, we find a number of female operators, demonstrating how the production work is evolving and modernising.

Daniela is one of them. We see her at work on an "ergon nt" cell, one of the SCM purchases that Ravaglioli says he is most satisfied with. It is a particularly advanced system for nesting machining, with an automated loading and unloading system.

"Our biggest requirement was to deal with unloading all the cut panels in the nesting cell as best and efficiently as possible, as our components are completely different from one another and it is not possible to remove them from the worktable by pushing them out - adds Paolo Ravaglioli -. We needed a solution designed around our requirements, that could take both the finished parts and production scraps and transport them along the conveyor belt, on which they would then be separated and labelled".

SCM's "ergon nt" solution gave Diesse Arredamenti the opportunity to achieve this, and that's not all. We are talking about a cell capable of machining non-stop and without any drop in productivity, over a number of years, while doing several shifts per day.

Thanks to the double worktable and the presence of several operating units, it's like having two machines in one, as well as the relatively reduced bulk for cells in this category.

Furthermore, its integration with the automated loading and unloading system is the best way possible to machine delicate parts, as the panels to be machined can be placed directly onto the machine's worktables, with the considerable added advantage of further protecting the operator.

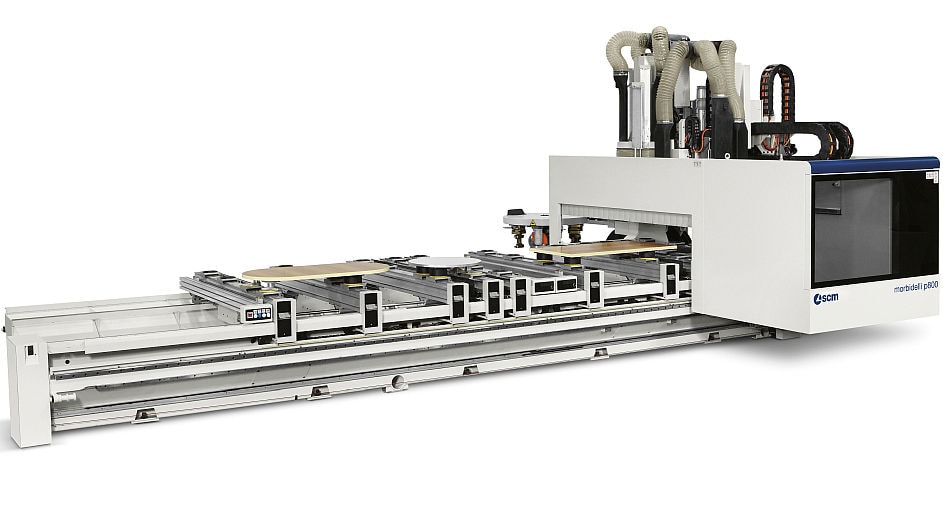

Alongside the "ergon nt" we find another of SCM's state-of-the-art machining centres, the "morbidelli p800", for drilling routing and edge treatment. A solution that allows for "just in time" work and for the highest standards of quality to be achieved on the panels ready to be assembled.

"SCM provides positive consulting and after-sales relations because our company works on double shifts and technical support is an essential factor for us - concludes the owner of Diesse Arredamenti -. Thanks to the new digital services, we can interface with SCM technicians simply and rapidly to solve any problems and this helps us a great deal to keep the production flow running".

Fill out the online form to be contacted by a salesperson