Giessegi's philosophy is leading the way in “made in Italy” furniture

Furniture Technologies

Numerous strategic choices have accompanied Giessegi's success over the years: speedy production and large volumes, yet with a superior custom design and quality, compared to the standards of mass furniture distribution. A connected, integrated and autonomous factory. A state-of-the-art SCM engineering project to machine panels, capable of creating two thousand living spaces per week,ready for delivery in 10 days.

Not everyone could take over a large company as an employee, taking the helm and transforming it into one of the largest furniture empires in Italy. Because that is what Giessegi Di Appignano is today; located just a few kilometres from Macerata in the heart of the hills in the Marche Region.

This could be a way of summarising Gabriele Miccini's most recent life story - electronic engineer and CEO of Giessegi Industria Mobili. He faced one of the most important challenges of his life when, in 2015, he ended up taking the helm of the company where he was working for as a programmer.

From that point onwards, he involved his sons Federico and Giacomo in the project. Most of all though, he revolutionised the factory and expanded it, fully reorganising production in an Industry 4.0 logic, and making more eco-sustainable choices, like the use of methane heating.

He even had a road built, while impacting as little as possible on the surrounding environment, to provide the company's numerous warehouses with a logistics that measured up to the standards of their significant figures. We are talking about a unique organisation, in a town of no more than 3,000 people, with more than 500 employees, a turnover of 110 million and an overall production area of 100 thousand square metres, where around two thousand living spaces are produced each week, including bedrooms, kids' bedrooms, living rooms, wardrobes, contract and office furnishings.

Being big was the engineer's key objective and to say that he was successful is an understatement. All you need to do is think of the expansion of 24 thousand square metres brought to a conclusion in recent years. Behind all of this, a clear logic and philosophy.

The first strategy is the product.

“Our focus has always been on offering a wide range of mid-high quality products at a highly competitive price” explains Miccini some of whose clients include a number of the best well-known large-scale furniture retailers in Italy. “We have always manufactured modern furniture for the home, though we have never wanted to deal with kitchens or modular furnishings. Ours is an industrial production of large volumes, but we offer better quality than standard products and more custom design".

Almost 90% of our turnover is generated in Italy but Miccini's next challenge is to increase the amount destined for export with contract work.

Uniqueness is also the logic behind our production processes. At Giessegi, there are basically three factories working in one, all with the same sizing, square-edgebanding and drilling technologies, and differ only in the thickness and size of the panels they work on. This organisation means production can be speeded up and waste reduced to a minimum.

One choice that proved successful from the outset was the decision to dedicate an ad hoc department entirely to "customised production" for those "special pieces" that allows for significant flexibility without compromising the production standards in other departments.

SCM has been a part of these strategic choices for a number of years. "We wanted a single technological partner and we have always had excellent relations with SCM" confirms Miccini "Having a single supplier means better understanding of the philosophy, how the machines 'reason' and how they have to be handled. Anyone dealing with large volumes must make high quality technical choices: this is the case with the sizing machines and squaring-edgebanding machines, drilling machines and machining centres".

Miccini has always been a pioneer. To mention just one example, it was one of the first furniture manufacturers in Italy to adopt the laser edgebanding to excel in the quality of the finished product and, a few years ago, they chose an extremely powerful, precise line: “stefani ssb laserline”.

The automation lines purchased recently following its latest expansion are also SCM manufactured. "We chose to be autonomous and opted to incorporate semi-manufactured production into our plant which was previously purchased externally. This allows us to be faster nowadays, with delivery times of ten days and, as a result, to be more competitive in a market where, with the increase in on-line sales, the time factor is ever more crucial". Furthermore, Miccini, managed to recover margins originally set aside for suppliers, by improving the company's balance sheets. "By recovering assets, we have managed to pay off the new plants in a shorter time period than previously expected".

The logic of Giessegi's helmsman is very clear: "A line has to be complete, so it should include sizing, square-edgebanding and drilling".

All of SCM's automatic lines are equipped with Maestro active watch supervision software, integrated into the company's IT system. Maestro active watch allows the production process to be managed and controlled, for example, by monitoring in real time the state of individual machines and the entire line, optimising production performances. Maestro active watch also creates a two-way interconnection with the factory's IT systems, allowing part programs to be loaded remotely from office to factory and returning production reports that can be analysed in the office.

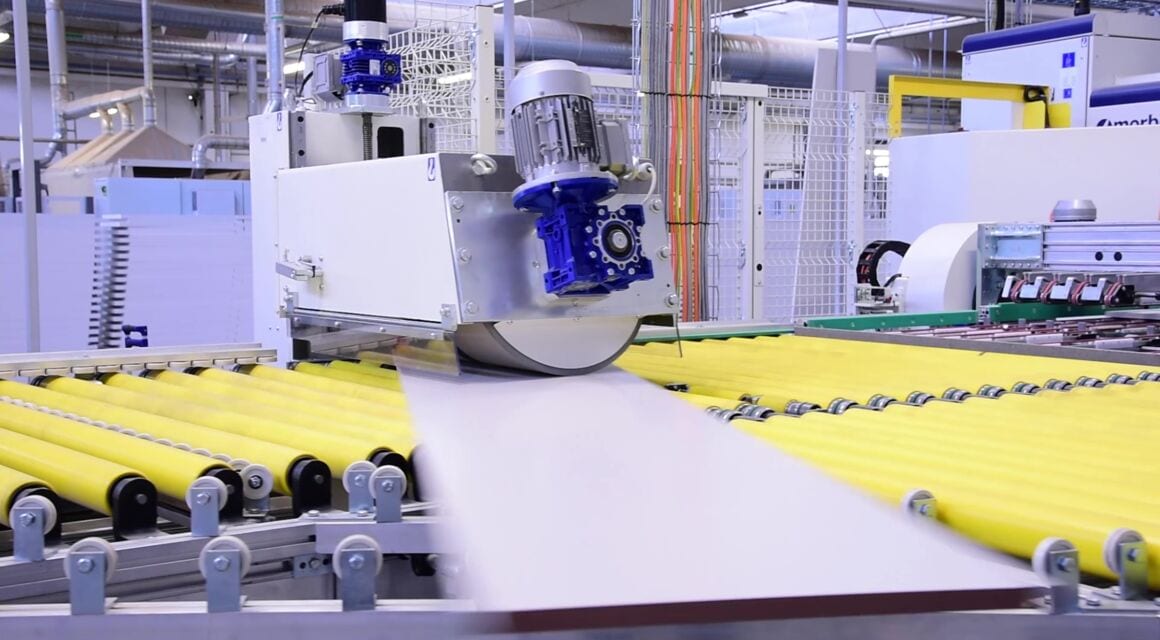

The sizing line with a production capacity of 140 cubic metres per shift, sees the "gabbiani a3" angular sizing machine take centre stage with "mahros stacker" unloading station to further speed up the process times. The line includes two different loading areas depending on the size of the machining panels and a cutter unit to further differentiate the panels before they are sorted and stacked. The “gabbiani a3” angular sizing machine, for its part, stands out thanks to its high level of automation and offers all the benefits of the range such as the FlexCut device that allows for complex cutting diagrams to be achieved in a shorter space of time.

The squaring and edgebanding line processes 6000 panles per shift, consists of automatic "mahros brush" loading and unloading systems, two double-sided "stefani sb" squaring-edgebanding machines and another automatic "mahros" system to rotate the panels by 90 degrees. As well as its high productivity levels, other advantages of the “stefani sb” include the high level of precision and versatility with which the machine permits the use of different gluing techniques, always producing excellent aesthetic effects.

The process is completed with two automatic lines with drilling centres ideal for large batches. The first line has a production capacity of 5000 panels per shift and includes two “morbidelli z100” drilling machines that stand out for their top quality finishing and precision, one of them being entrusted with dowelling functions. The second line, turning out 2000 panels per shift, has two “morbidelli pwx100”: high level of electronic automation, elevated productivity and machining quality with variable batches are the main advantages of these SCM drilling solutions.

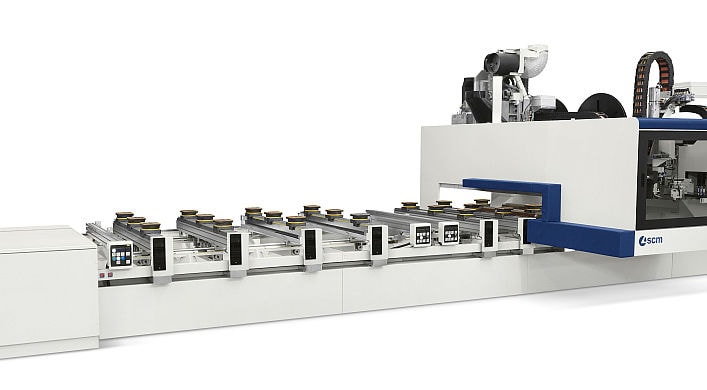

The engineering project devised by SCM for Giessegi also includes two “morbidelli p200” machining centres for drilling, routing and edgebanding, with the innovative edging unit capable of applying edges on panels that can be as thick as 80 mm and the exclusive HE-POD suction cups that allow for the size of the work table to be used to the full thanks to alternating lifting of the panels.

Being big was our aim and who knows whether the choice of advanced technological solutions and adoption of a forward-thinking production strategy will not push Giessegi towards new and even more ambitious goals.

Giessegi

Fill out the online form to be contacted by a salesperson