News

RT-F 1400 Compactness and performance at your service

RT-F 1400 is the ideal 5-axis CNC machining center with rotary table for machining workpieces with dimensions up to 1000x800x400 mm, for sectors such as motorsport, automotive, marine and aerospace.

CMS has the right profile for you!

In today's increasingly competitive manufacturing landscape, maximum efficiency and precision are key to success. CMS machining centers with bar tables are the ideal solution for companies that want to raise their productivity to new levels.

CMS tao-x: book your demo now!

High-performance moving bridge machining center

Efficiency, strength and precision? CMS vm30k!

The vm30k 5-axis machining center represents the perfect combination of innovation, strength and versatility. It is designed to meet the needs of industries working with both aluminum and steel while ensuring safety and precision.

CMS transports and preserves your ideas! All-round solutions for isothermal walls

Thermally insulating a truck body can make all the difference, especially when transporting goods that are sensitive to temperature changes or getting fresh, well-preserved food to our tables. Isothermal walls are the structural basis of the insulated body, and bring significant benefits because they:

Cutting soft materials: the 5 questions you should ask

The versatility of waterjet cutting technology enables a wide range of materials to be processed in various sectors, such as: construction, thermal and acoustic insulation, automotive, aerospace, railway, packaging, footwear, sealing.

Discover the full range of CMS technologies for the processing of composite materials!

CMS provides customers with a comprehensive machines lineup and innovative manufacturing solutions to enhance customer productivity and business sustainability. CMS Advanced Materials Technology and Bercella srl, a leading Italian company in the field of composite materials for aerospace, defence and motorsport applications, have worked together on a project aimed at showing the effectiveness of their technological solutions, with a focus on high know-how in the production of composite materials and equipment.

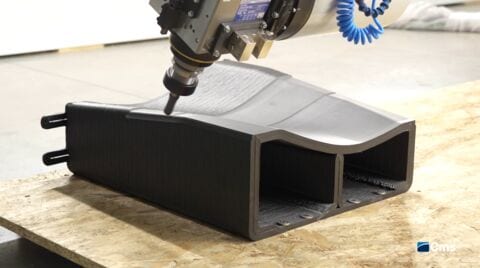

Additive Manufacturing: composite tooling gets 10 times bigger!

5 reasons to choose CMS Additive Manufacturing:

Cutting composite fibers or honeycomb? CMS has the technology for you!

In sectors such as aerospace, automotive, general transport and renewable energy industries, ultrasonic cutting technology offers a clean and precise solution for cutting composite fibers, i.e. the fillers used in structures, especially honeycomb and dry carbon fiber.

Are you already thinking about your next vacation? Discover how campers are built with CMS!

Summer isn’t over yet and we’re already talking about leaving for new adventures and destinations! Many people choose to move by RV or camper so that they don’t have to give up the privacy and comfort of home.

Here are 4 reasons (+1) to consider the vm30k for your machining!

Here are 4 reasons (+1) to consider the vm30k for your machining! You can make aluminum and steel dies with finishes of Ra1.6 micron (μ) or better. It has a removal capacity of over 3000 cm³/min for aluminum and up to 500 cm³/min for steel.

CMS Monofast 3D: quality and precision in the production of knife handles and grips.

CMS Monofast machining center has been enhanced and equipped to meet the most specialized needs of our customers by unmatched performance in machining knife handles and grips.

M.D.C. Design and CMS Kreator Ares: 365 days of Additive Manufacturing

We are back from M.D.C. Design, a leading company in the automotive sector, which, sensing the potential of Large Format Additive Manufacturing (LFAM) technology, installed the first CMS Kreator Ares, now more than a year ago. We met Paolo Isabello, one of the owners of M.D.C. Design, and asked him to give us a brief account of working and experimenting over this last year.

International Sales Meeting Advanced Materials and Plastic 2023

Last week we had the pleasure of having the Advanced Materials and Plastic International Sales Meeting at CMS headquarters. Throughout the week we focused on several exciting and involving activities that encouraged intense collaboration among our team members. Training sessions and debates helped us create a shared vision and strengthen our strategy for the future.

JEC 2023

We have just got back from JEC 2023 in Paris! We spent three amazing days showcasing our products and meeting so many of you who came to see us. We would like to extend a huge thank you to everyone who stopped by our booth.

Come to discover CMS kreator at JEC World!

Discover all the latest developments with our CMS kreator. Here’s the NEW OFFICIAL VIDEO!

Two days to innovate

An important event in collaboration with Hufshmied took place on April 4th and 5th in the CMS headquarters.

Novation Tech & CMS: A Carbon-Fiber Partnership

A genuine partnership exists between CMS and Novation Tech, a leading European company in the processing and production of carbon fiber and composite material components. Novation Tech has two production plants based in Hungary and Croatia, with its main headquarters in Montebelluna, Treviso, where its offices, R&D department, and part of its production are located. Here is where we meet Luca Businaro, CEO and Novation Tech partner.

5 reasons why you should consider cutting composite materials with waterjet technology.

The principle at the root of a waterjet cut is simple but still surprising. As the name suggests, a jet of water is projected out of an opening at more than twice the speed of sound. The intense flow of pressure allows the water to cut practically any composite material and any kind of metallic alloy. The water flow is very fine, usually between 0.75 mm and 1.20 mm, which means the flow of water can cut details that are impossible to achieve with conventional cutting tools.

OMR & CMS: an absence of technological limitations leads to continuous improvement

In order to fully understand the importance of the OMR group, one needs to start from a list of some of its most valued clients: Iveco, Fiat (Stellantis), Ferrari, Maserati, Renault, Audi, General Motors, BMW, Lamborghini, Alfa, Jeep, Bugatti, Dallara, Zoox as well as customers in the agricultural machinery and earth movement sector such as CNH and Dana.

Irrespective of your core business, this technical evolution might interest you.

Automotive, motor sport, mold maker or model maker? This new entry should definitely interest you!

Additive Talk (Ep.10) - 3DZ: 3D Printing Technologies

In the tenth episode of the series, we explore the selection process and introduction of a 3D printer into a company with Cristian Parmeggiani, Italy Country Manager at 3DZ, and Maurizio Bernini, Product Manager Additive & New Technologies at CMS.

Additive Talk (Ep.9) - Airtech Advanced Materials Group

The ninth episode is entirely dedicated to the role that materials play in Additive Manufacturing technology.

The challenge of electric cars also involves the battery case materials and processes

The battery cases for the electric vehicles (battery cases, also known as shells, casings or battery packs) have a very simple purpose: to store and protect the battery modules. They come in different shapes and sizes and can easily be adapted to the battery modules’ different features. While numerous casings are currently produced in steel (or a combination of aluminum and steel), in the long term, aluminum seems to take the upper hand, especially thanks to its lightness and favorable technical features. It is, therefore, easy to understand how so much attention is focused on the battery case market and is always technologically more advanced both in terms of material and processes.

Additive Talk (Ep.8) - Design for Additive Manufacturing

PUNTOZERO 3D is a team of experts capable of helping companies involved in Additive Manufacturing to make the most of the opportunities available, setting out the paradigms of engineering planning for different additive technologies. It is an organization capable of creating the best products, helping companies innovate and resolving problems with a planning approach outside of traditional frameworks.

Desire for travel and holidays in a camper van or caravan (and to know how they are built)

With summer comes the desire for holidays, travelling, adventure and freedom. The camper van and caravan are the ideal combination of these 4 desires. Since the 1980s, CMS avant caravan has been the best option available on the market for the production of side walls, flooring and roofs on camper vans and caravans. Motorhomes and panels for refrigerated trucks can be added to these.

Always choose the best to stay at the top

Briccoli Modelleria is an Italian company that designs and produces foundry models, molds and equipment. The company’s motto reads “Since 1885, we have been building a future with the oldest art known to man”. The experience matured throughout its history and the technological investments made have allowed it to expand dynamically and flexibly in the market, so they can provide instant answers to a target with different needs, manufacturing high-end products with precision delivery times.

Additive Talk (Ep.7) - University education

In this seventh episode, Luca Rinaldi will take a close look at university education together with Serena Graziosi, professor at the department of Mechanics at the Politecnico di Milano. Professor Graziosi is an expert in Additive Manufacturing Design and provides us with an in-depth explanation on the role people like her play in the academic world and beyond.

Connected machines are the present, not the future!

Mistral Optical is a company producing, on average, 50,000 pairs of glasses a month. It is located in Quero Vas in the region of Belluno, global center for eyewear. Working on a pair of glasses is a complex operation that needs to find the perfect balance between expert manpower and automated work done by machines. There are about 30 intermediate stages. Knowing exactly at which stage a product can be found in the various processes, at any given time, is the turning point in the entire production chain; representing real added value in the service offered to one’s clients. Precisely with this in mind, the company decided to connect the numerous CMS machines together, from the latest additions to older versions.

Additive Talk (Ep.6) - The History

Maurizio Bernini went to the prestigious Fraunhofer IWU Institute in Chemnitz to interview Christopher Schlegel for the sixth episode in this series.