brembana venkon

(512) 931-1962

5-axis monoblock CNC saw machine

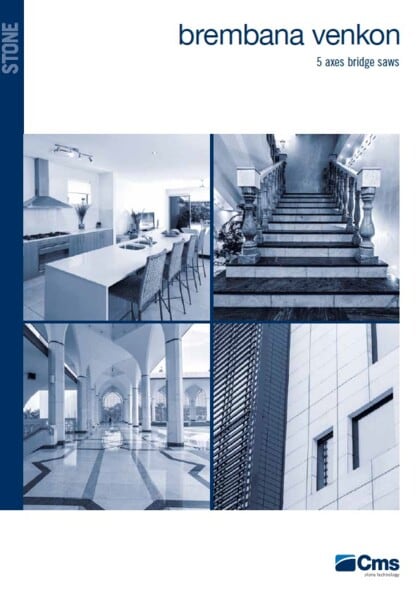

It’s the new generation of a numerically controlled 5 axes Bridge Saws. Extremely compact and easy to install; it doesn’t require any foundations, even as a possibile re-installation. The machine is built with the needs of workshops in mind and it is used for cutting slabs up to 200 mm in thickness (with blade Ø625 mm) of natural stone, synthetic stone, and ceramic.

The weight of the machine, up to 4.4 tons, ensure perfect rigidity for the production of:

- kitchen countertops

- vanity tops

- wall panels for interiors and exteriors

- flooring

- doorsteps, staircases, and thresholds

- street furniture

UNRIVALLED MECHANICS

The weight of the machine up to 4.400 kg ensures the optimal absorption of the stresses derived from machining, guaranteeing a high constant precision over time. This machine base fixed directly to the ground, without the need of building work, increases the machine and performance.

WE WORK SAFELY

Blade automatic redressing station can be activated by a specific function on the operator panel.

MAXIMUM FREEDOM FOR YOUR PROJECTS

Rotary axes are fully interpolated with linear axes: the machine can therefore perform 5-axis machining with a tool and/or disc if necessary.

| Blade Diameter | 350 ÷ 625 mm / 14 ÷ 25 in |

| Maximum working thickness (90° Saw unit) | 200 mm / 8 in |

| Electrospindle | 14,3 kW / 19.5 HP |

| Electrospindle revolution | 0÷5000 rpm |

| Head revolution (C axis) | ± 180° (360°) |

| Head inclination (A axis) | 0° - 90° |

| X axis stroke and speed | 3950 mm / 156 in - 30 m/min |

| Y axis stroke and speed | 2450 mm / 97 in - 25 m/min |

| Z axis stroke and speed | 400 mm / 16 in - 7.5 m/min |

| Workbench dimensions | 3600x2000 mm / 142x79 in |

| Minimum space required for installation | 6400*x4110x3020 mm / 252x162x119 in |

| Overall machine weight | Up to 4.400 kg /9.700 lb |

*excluding the space necessary for switchboard access

Fill out the online form to be contacted by a salesperson