stefani rocket U

(512) 931-1962

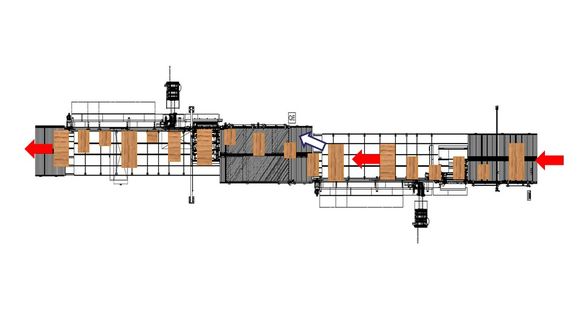

stefani rocket U is a high productivity flexible edgebanding and squaring-edgebanding line composed of two single-sided edgebanding machines with panel squaring function connected by a roller and belt conveyor for panel translation.

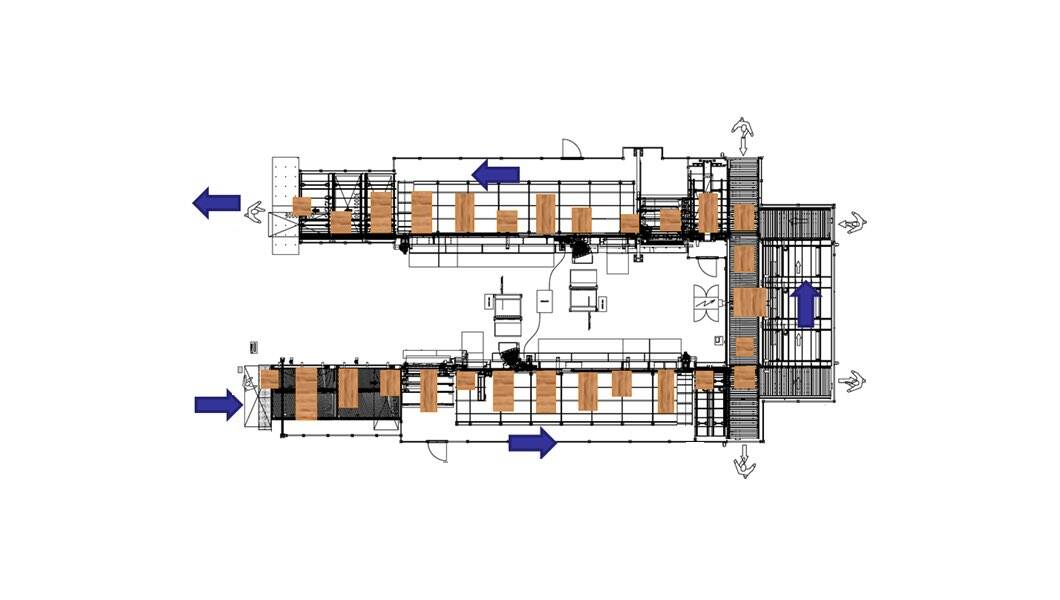

The U-shaped configuration of the line compensates for the lack of space inside the production area, ensuring a continuous flow of the process. The composition with single-sided edgebanding machines allows a high degree of flexibility thanks to the introduction of panels of different sizes with the same thickness.

It is composed of TR C180 conveyor and two single-sided edgebanding machines, stefani one or stefani sb one model. Both machines in left or right execution.

U-shaped lay out of the line

Thanks to the U-shaped lay of the edgebanders and the conveyor, the processing line is very compact thus allowing to optimize the required production space.

EdgeStore Manager

The automatic learning system via barcode or QRcode reader combines the program to be executed with the correct edge for extremely simple and fast management of the edge coil change. Thanks to the dedicated interface of the Maestro active edge software, all edge information (name, color, thickness, consumption, etc.) are always available on a single screen.

BN+ infeed device

The correct panel infeed is essential to comply with the shape and final size of the component.

This is possible thanks to the automatic infeed device by belts with dynamic movement of dogs for longitudinal insertion in the 1st passage and transversal insertion in the 2nd passage. Suitable for panels already squared or to be sized and squared.

|

Machinable dimensions with lengthwise feeding

(length x width) (min/max)

|

mm | 250x130 / 3000x1200 |

|

Machinable dimensions with crosswise feeding

(length x width) (min/max)

|

mm | 180x250 / 1200x3000 |

| Possibility to size the panel | - | YES |

| Change of colour, thickness, edge protection film | - | YES |

| Panel dimension change | - | YES |

| Groove position and depth (in flexible mode) | - | YES |

| Glue dosage change | - | YES |

| Addition of a panel during Batch 1 machining | - | YES |

| Homogeneous panel management | - | YES |

| Panel re-machining | - | YES |

| Edge bander model | - | stefani one / stefani sb one |

Request information

Fill out the online form to be contacted by a salesperson

Thank you Your message has been sent.

Error! Something wrong has happened