Arnografica

Graphics industry technologies

ELMAG AND ARNOGRAFICA

Traditional offset without forgoing the UV LED

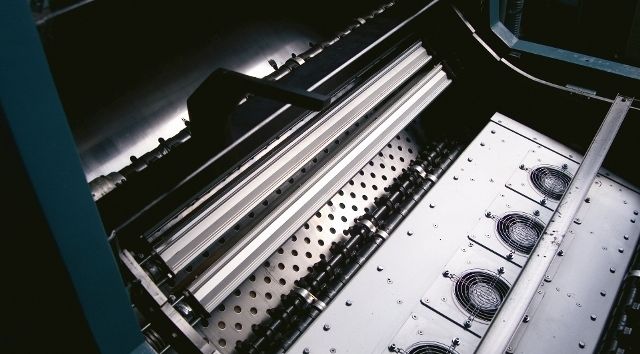

Thanks to a partnership with Elmag Superfici, Arnografica fitted a UV LED curing system on the NEW TGI offset, formerly the Aurelia 520 project. The traditional offset - UV LED duo proved to be a winner.

Arnografica, based in Cardano al Campo, not far from Varese, and long-standing supplier of 50x70 commercial printing was founded from the passion of the forefathers of the Cagnoni and Vanetti families in the 1970s. Nowadays, it is an important business in the paper goods industry, to which it offers a full service.

Arnografica's decision to put its trust in offset machines from a project by the former Aurelia brand has proven to be the right strategy over the years, proof of which is the quality performance of a product focusing on a market niche that expects good quality for small/medium volumes, the company's real core business.

Furthermore, Arnografica's printing department, that already had three multi-colour offset machines, was able to benefit from a unique management/maintenance programme and the use of technical products that could be used across the board on all the machines.

FLEXIBILITY AND EFFICIENCY

The cooperation between Roberto Finetti, Graphic Division manager at Elmag, Mario Cagnoni and Maurizio Vanetti, owners of Arnografica, dates back to 1991, but talk of a UV LED polymerisation project started at DRUPA 2016.

The relationship based on reciprocal respect and trust between Elmag and Arnografica proved a winner, smoothing out an initial perplexity that placed the highly innovative UV LED system in contrast with a machine with its consolidated design and one so highly esteemed within the company. Arnografica's decision gave the company an important technological boost, as well as significantly expanding the production possibilities in the printing department without turning it upside down due to a change in the machine operators' modus operandi.

The owners of Arnografica are pleased with the new UV LED system and can claim "that it strengthens the company service both in terms of efficiency as well as in terms of delivery times because it is an immediate, safe technique". Indeed, the sheets leave the printing machine dry without the need for slip sheet proof powder or other treatments, allowing for any subsequent veneering to be done to the print without any problems. The Elmag UV LED system's high level of flexibility means you can forget this system is even in the machine. The mercury-free UV lamps produce only a minimum impact on the environment and avoid problems linked to their disposal. As they do not produce ozone, they don't create oxidisation on the gripper arms or the printing cylinders. The result is an odour-free, quiet working environment. Furthermore, the same production speed can be reached on paper materials and especially on transparent and metallic plastic laminates. "This technology is the future of the paper goods industry" continue the owners. "The chemical industries are making huge progress and we aim to replace all the traditional UV systems with UV LED systems because they bring advantages in financial, environmental and efficiency terms".

The results of this new system of curing are promising: "We have recorded positive signs of growth, we have tried different kinds of ink and the polymerisation takes place at depth both on the paper and on plastic material where the LEDs polymerise the inks cold, producing huge benefits on the printing registration and with no deformation on the support".

Arnografica (Italia)

Llena el formulario para ser contactado