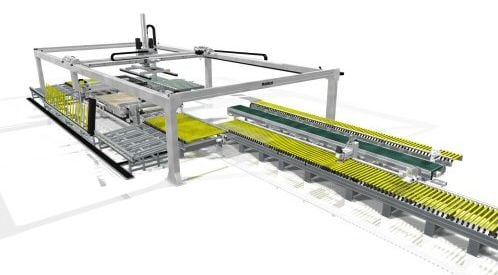

gabbiani gt 2

(512) 931-1962

The advanced solution with complete standard equipment that guarantees the best price-performance ratio.

Speed, precision, flexibility and productivity mark out gabbiani gt 2. It has been designed to assure high performance in a developed industrial context of just in time productions. With its range of options it can be used to cut plastic, acrylic and synthetic panels.

HI-TRONIC DEVICE: high technology on the saw carriage

Very high quality finishing cutting standards together with high speed and precision with the total electronic control

of the blades. SCM patented.

FLEXCUT 1/D and 1/S: more cuts in less time

High efficiency due to the use of 2 pushers with a completely independent stroke.

Drastic reduction in machining cycle times due to the simultaneous processing of several bars with different cuts.

In version 1/S, the unit is fitted with a single gripper, giving two independent cutting axes at an extremely low price.

In version 1/D, extreme flexibility is achieved as the mobile unit is fitted with two grippers, the second one can be excluded, therefore guaranteeing a wide variability in the width of the strips that can be gripped.

PRISMATIC GUIDES WITH RECIRCULATING SPHERES: maximum linearity and minimum friction

Increased productivity capacity both with high speed, that can be reached during the feeding stroke (100 m/min with a single sheet, 50 m/min with a panel stack), and a return stroke (up to 170 m/min).

The centralized lubrication, verified by the guides control, guarantees the complete lack of maintenance.

Loading platform: when sturdiness and precision make the difference

The lifting system, running on 4 large trapezoidal screws, as well as to maximize the load capacity in any material and format, always ensures parallel lifting of the stacks of panels avoiding downtime and achieving maximum productivity.

Galaxy T3 110 with FlexCut 1S

Llena el formulario para ser contactado