Atl

Tecnologies pour le meuble

A heap of sofas!

Impressive. It doesn’t happen every day to see a production line churning out something like 1,200 sofas a day! With specific standards: quality to the smallest detail and safety. In partnership with Scm Group for over twenty years.

Franco Tartagni welcomed us with a broad smile. A huge factory, over 45 thousand square meters, where everything is organized, cared after, even pleasant... it really looks as if the factory were smiling. There are problems, of course, things to improve and answers to give, but the overall impact is quite positive: it’s a “nice place”... It's the Faenza headquarters of Atl, a giant of upholstered furniture, 82 million euro revenues in 2016. Tartagni is one of the founders of this company, a long success story of competence and passion, desire to do something good for yourself and the community, determination to carry on…

“This is the result of forty years of history”, said Tartagni with satisfaction. “It was 1976 when my business partner Luciano Garoia and I decided to start our own business. This area is home to a big upholstered furniture district and we worked in a company specializing in the production of polyurethane for padding and stuffing. In those years, there was a lot of work and it didn't take much courage, I admit... We were happy that some colleagues decided to follow us in the new adventure, and in the end we were eleven people plus two young girls, so young that they couldn’t even be business partners. So we created a cooperative called Cipes, managed by Garoia and myself, and still today – after many years and much water flown under the bridge – this co-op is a pillar of Group Atl, holding a 30 percent share. The first year was terrible, someone feared that other could imitate our initiative, messing up a “conventional” business sector. We held up strong, and over the years, we learned to make everything, providing our customers with “white stems” ready to be upholstered. We also acquired two joinery workshops, now incorporated in our new Faenza site, to make stems, structures... We grew strong, and little by little we started to make finished sofas, ready to be delivered to end customers. In 1997, we were selected as suppliers for a big retail group, and in 2002 by a high-end store chain found all over the world...".

Business went full sail ahead: with startups and acquisitions, the group expanded, increased its competence, approached the market with a complete offer, from design to finished sofas for sitting rooms or offices. Major partnerships were established, generating new opportunities: from residential to contract, plus the capacity to target different market segments, from consumer products to leather sofas with sophisticated design.

Each day, the 45-thousand-square-meter factory in Faenza ships 1,200 sofas, as already mentioned. Here, 500 out of 600 employees work, plus another 300 in the supply chain, all involved in the production of sofas, the processing of polyurethane and the workshop that supports all the manufacturing units of the group. The Bertinoro site, extending over 10 thousand meters, hosts the production of leather and high-end furniture.

But what is really impressive is the new Faenza factory, “…a high-flexibility plant, built to enable us to do what we decide to do every day”, Tartagni said. “For instance, if we have planned to ship 1,125 sofas today, by this evening 1,125 sofas will be loaded onto our lorries. Consider that each day we handle at least 60 different models, and each model has about twenty variants, which means that the 1,200 sofas we make each day on average include 300 variants of shape, color, size, number of seats, functionalities... Each "shuttle" in our plant is a bench where a sofa is manufactured, from assembling the first wood pieces up to the finished product, withe accurate time schedules and an IT system that "notifies" to each workstation which materials, mechanisms or fabrics must be available to create the next sofa".

How can everything run smooth?

“Thanks to organization and technology, even if making quality upholstered furniture is still a handicraft job, where human skills and manual work make the difference. Especially in the final stage, upholstery, when the sofa or armchair is “dressed” piece by piece, element by element, perfectly “to measure”. And for leather sofas, the handicraft skills of workers are the real differentiator...

Where can technology lend a hand?

“In cutting operations, both for wood, fabrics and padding materials. We have optimized all cutting procedure to “industrialize” the preparation of semifinished materials to be assembled by our craftspeople. In the first period of our joinery business, when we purchased two workshops – which were strategic for us as they allowed to manage the entire production chain – we only had few conventional machines, really basic equipment: band saws, some planing machines, a multiblade saw, cut-off saws and a few more. Also in terms of safety, with advanced technology we have made great progress. When we decided to increase the safety of specific process stages, we got in touch with Scm Group. It was 1998 and we found out they had a machine that was a perfect fit for us, to process wood and panels in full safety: we immediately purchased one and that was the beginning of an enduring partnership giving great satisfaction. We have grown together, we have got to know each other and learned to find the most suitable solution. They installed our first panel saw, and more recently an angular machine: both products have enabled us to make a huge step forward in terms of productivity and safety. You see, if we are what we are today, if we can deliver 1,400 sofas in a day, that’s because we have invested in people and technology: applying efficient organization principles, keeping up with technological innovation has resulted into lower production costs, leaner processes, improved ability to provide customers with what they really want. All of this with maximum safety, a value we never give up".

And if you look around the big workshop in Faenza, you understand what Tartagni means: heaps of components, wooden elements, ready to feed a production chain that never stops; approximately forty people working in two shifts to prepare strips and shaped elements, which will be assembled to make sofa and armchair stems and frames.

“A well-made sturdy wooden frame represents a small fraction of the final costs of upholstered furniture. But at Atl we believe a strong structure is essential for a good sofa. It is not worth saving on this part, so we use top-quality panels and wood, just like all the raw materials that flow into our factories. Mass production, as I have already explained, requires that there are no issues or interruptions along the process. It is definitely not worth jeopardizing the efficiency of our assembly line for a low-quality panel or a piece of wood that breaks up suddenly".

“A few months ago we purchased our third Gabbiani panel saw from Scm, which I consider a small revolution in panel cutting. We defined this project with the engineers in Rimini, as we were looking for a solution offering maximum flexibility. The result has exceeded our expectations and now we have a cutting line with amazing productivity levels; we can handle all types of materials without any problem, not to mention the convenience of aggregates to turn the panels and process them as if they were on an angular machine, relieving the operators from heavy-duty tasks, as all they have to do is load the panels and watch the pushing bars and vacuum cups do the rest of the work!

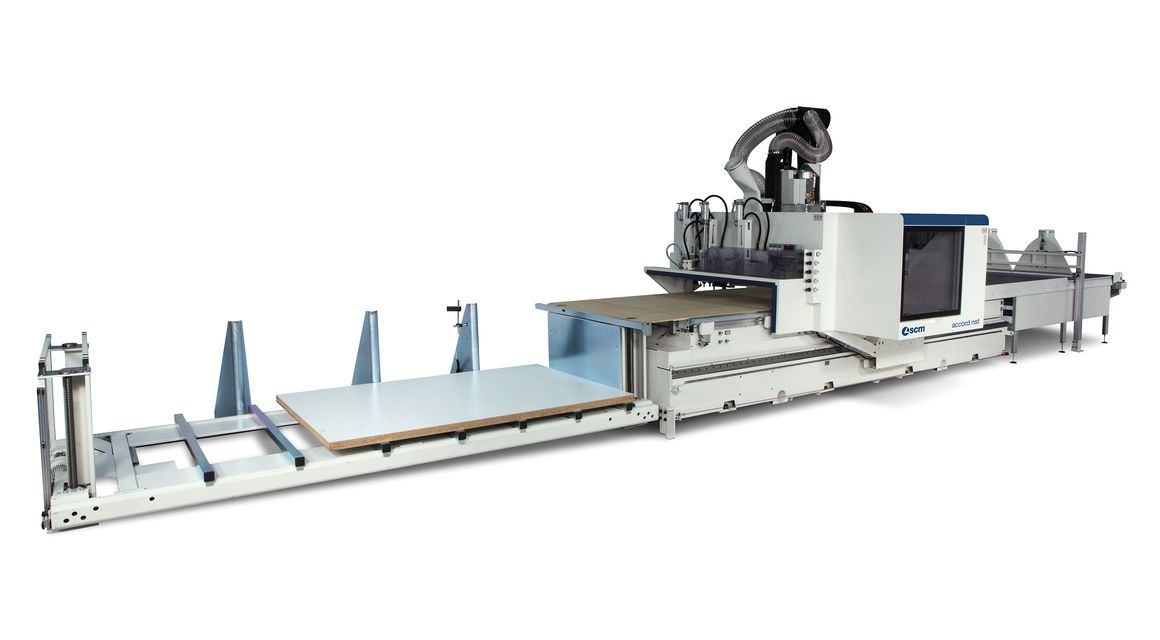

It’s a highly versatile and powerful machine which has changed the working method of our workshop. we were always short of time, now the production of most semifinished materials is executed with great efficiency and safe margins, which is very important for a tight schedule like we have. We are so satisfied with this approach that we are considering replacing the shaping machines for panels with a nesting working center, I am sure it will bring the same satisfaction we have had so far, up to the latest investment. There is another aspect of our partnership with Scm Group that I love to mention, namely the quality of service. Our plants must be reliable in any situation, that’s why we have chosen technology partners who can provide the best assistance”.

Atl Group Spa (Italy)

Product highlights

Remplissez le formulaire pour recevoir de plus amples informations