SLIMCURE - UV modular units - water cooling

(512) 931-1962

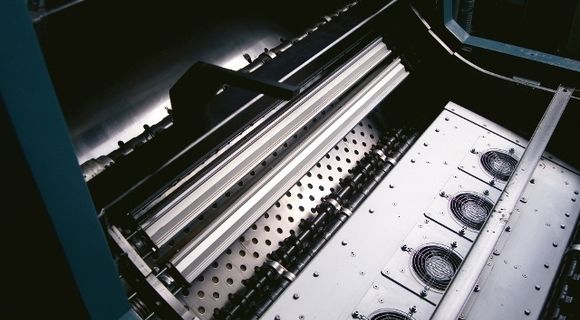

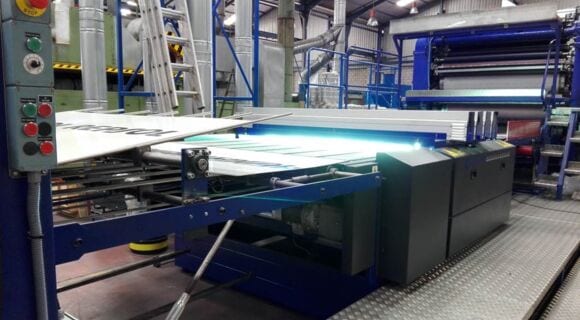

If there are some space problems, it is necessary to use small UV modules mounted directly inside the printing machine. Being very small also the heat dissipation surfaces are reduced and therefore it is necessary to resort to a fluid cooling. The Labes reflector, studied by Surfaces, allows to obtain a perfect focus at different distances and is therefore able, adapting itself to any mechanical construction to always have the maximum polymerization performance.

POWER: The lamps used are the result of thirty-year selection. They can work at a maximum power of 200 W / cm and, thanks to the electronic igniters, they have a power of stand by equivalent to 15% of the maximum power used. Each lamp has a three-phase power supply, sensors for controlling the overturning of the reflector in the case of standby or steady line and continuous adjustment of the working power of the manual type or, optionally, controlled by the printing speed.

Fill out the online form to be contacted by a salesperson