Design. Idea, planning, creation.

For over sixty years, Scm Group has been working with craftsmen, firms and large industries which every day also focus on design solutions with wood, marble, plastic, composite materials and glass. Producing simple consumer goods, doors, propellers for wind farms, windows, houses, aircraft parts, stairs, ship hulls, glasses, furniture…

Scm Group is aware of its contribution and has chosen to support particularly significant experiences, to propose itself as a technology partner for well-known companies, emphasising in this way its mission: create tools so that others can give shape to an idea!

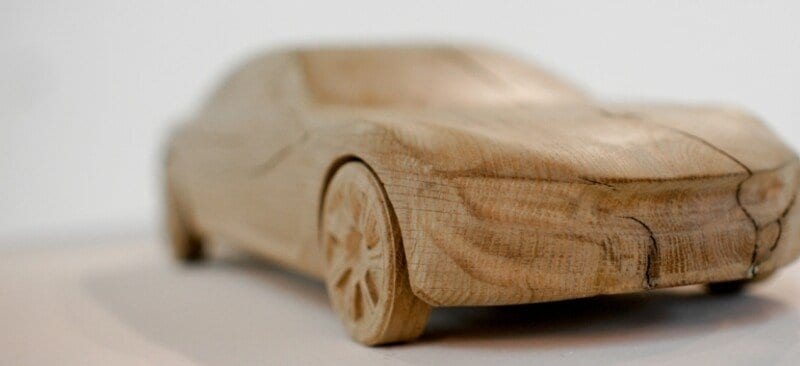

Pininfarina Cambiano & The Briccole of Venice

A harmonious link between design and technology.

Modelled on the pure, cutting edge design of the Pininfarina Cambiano, the Briccole, wooden posts used for mooring in the Venetian lagoon, are transformed by Riva 1920 using the technology of the Scm Group and Alphacam software into a perfect sculpture and a symbol of Italian excellence worldwide.

CAMBIANO Luxury for sustainable mobility

With the Cambiano, Pininfarina proposes an electric luxury sports saloon concept car. Elegant and sporty, refined and comfortable, the Cambiano combines pure, cutting edge design with engineering research. The choice of name comes from the city where the group headquarters are based. The Cambiano represents the new Pininfarina and embodies the company’s expertise in terms of styling, design and research in the field of sustainable mobility. The Cambiano sets a new benchmark for environmental sustainability in the luxury car sector and boasts electric traction which amounts to virtually zero emissions in the city cycle and a level of electric autonomy that is higher than that currently available on the market. Perfect integration between styling and engineering has led to a plug-in extended-range electric saloon car that combines high performance with the usability and comfort of a luxury car. It has also been designed with a focus on the environment both in the power train and the choice of materials: this is the case with the interior made using recycled wood from the briccole of Venice.

SCM GROUP Superior technology, for simplifying complex ideas and turning them into reality

For Scm Group, the wood sculpture that reproduces the Pininfarina Cambiano represents a passion for Italian creativity to which it adds its own superior technology. With scientific precision, this technology transforms creativity into masterpieces and offers competitive advantages that last to whoever chooses the Scm Group. Today, producing technology means being aware of the needs and work methods of customers. It means knowing how to design and build complete factories to create the product that the customer wants to put onto the market. It means working in close contact with designers and architects. This is because the ultimate aim of technology is to simplify new ideas and turn them into reality.

RIVA 1920 Passion and Technology serving environmental sustainability

Technology and craftsmanship. For us creating the Pininfarina Cambiano was another opportunity to reassert our passion for wood and design which has helped us to grow by developing a project which was unusual for us and demanding but unique and inspiring. In this project, the Briccole of Venice are protagonists along with the curvy, elegant lines of the Cambiano. The Cambiano project seals our alliance with Pininfarina through the environmental sustainability of the briccola (recycled wood) and the engine of this limited production electric-powered model. This work has been made possible through the advanced technology we have in our company, technology produced by the Scm Group from Rimini and AlphaCAM-LICOM SYSTEMS and used to create the Cambiano on a scale of 1:1 entirely in wood. Environmental sustainability, design, cutting edge technology and craftsmanship are all part of this project that enhances the creativity of this team of Italian companies.

ALPHACAM CAD/CAM software from ideas to NC machines

The transition from CAD to 5-axis machines is the mission of the Licom Systems AlphaCAM software package, an ideal complement for companies in the wood furnishings industry as well as others who work in the most demanding of design environments. With AlphaCAM designers are free to choose their own work environment secure in the knowledge that all necessary information is transferred to production without the risk of seeing their own creativity “radically changed or suppressed”. A case in point is the development of the Cambiano interior which was first designed by the Pininfarina design centre and then skilfully processed using AlphaCAM Ultimate 5-axis milling and sent to the 5-axis NC machines. For large and small companies alike, AlphaCAM is the ideal software for making the most of CNC machines and helps to reduce time and costs and improve quality, productivity and efficiency. The expertise of personnel is vital to achieving significant results and a special mention goes to Marco Benetti who developed all the programs for Licom Systems.

Pieghevole pininfarina cambiano

Barrique San Patrignano

Scm Group is the top partner of the event featuring furniture and items made from reclaimed casks used to age the wine made in San Patrignano.

From San Patrignano to the United States, a long roadshow from May to October 2013, traveling through Boston, New York, Washington, Charleston, Miami, Houston, Chicago and Atlanta. A journey that tells the story of just a small portion of what happens every day in this community, the biggest in Europe, which has been welcoming young men and women with problems of drugs and social marginalization

for thirty years. An organization that needs no introduction, where attention to people, work and community leads to the re-birth of thousands of boys and girls, men and women. Just like the barrique wood is re-born...

Two activities of the community – excellent winemaking and a joiner’s workshop equipped with “Premium” machines by Scm Group in Rimini – resulted into a project called “Le botti rinascono a San Patrignano”. Using reclaimed casks where valuable San Patrignano wines have matured, the community created lamps, furniture, doors, toys, armchairs, chairs, small tables…

The items were designed by about thirty famous designers, including Claudio Bellini, Luca Scacchetti, Pierluigi Cerri, Michele De Lucchi, Aldo Cibic, Terry Dwan, Elio Fiorucci, chef Gualtiero Marchesi, Karim Rashid, Matteo Thun, Aldo Spinelli, Angela Missoni, Paola Navone, Paolo Pininfarina and another chef, Marc Sadler. Without forgetting Maurizio and Davide Riva of Riva1920 from Cantù (Como), who have been supporting this project since its official launch at the Milan Saloni in April 2012, recording great success among audience and critics.

The long US tour will also draw attention to Italy in general. That’s why the “Barrique project” was listed by the Foreign Affair Ministry among official initiatives celebrating 2013 as the “year of Italian culture” in the States, with a calendar including over one hundred cultural events and initiatives.

Scm Group will be the top partner, together with sponsors like Italy-America Chamber of Commerce in New York, Ice (the Italian agency for enterprise promotion and globalization), Friends of San Patrignano (a community founded in 2003 to help young Americans based on the same model of the original community), Foundation for Italian Art and Culture in New York; Fondazione Bracco, by the same-named pharmaceutical industry family; Poltrona Frau, an excellent brand in the production of seats and upholstered furniture; Msc-Mediterranean Shipping Company, a giant of maritime transport; Aon insurance and reinsurance group; Federalimentare and Federvini, complementing design with Italian taste, offering wine tasting experiences at each stage of the roadshow.

«We are honored to take part in this great adventure of San Patrignano and “made in Italy” in the United States», said Alfredo Aureli, general manager of Scm Group. «It’s an opportunity to testify our support and 30-year friendship with San Patrignano and their joiner’s workshop, where our machines are an established presence. But it is also a way to be close to the big and exciting world of design, to show what we believe in, our determination to provide tools that can turn a great idea into a great product. This is our mission: collaborate to make a dream, an idea come true. Improve life, make it more beautiful... a miracle that happens every day in San Patrignano! And I’m not talking just about furniture or wine, but people...».

Timetable |

||

| 7-8 may | BOSTON | City Hall |

| 18-20 may | NEW YORK | Poltrona Frau |

| 29-30 may | WASHINGTON | Ambasciata D'Italia |

| 6-7 may | CHARLESTON | US Custom House |

| 13-14 june | MIAMI | Showroom Poltrona Frau |

| 20-21 june | HOUSTON | Showroom Internum |

| 30 june - 2 july | NEW YORK | Fancy Food c/o Jacob K. Javits Convention Center |

| 9-10 july | CHICAGO | Field Museum |

| 13 september - 11 october | ATLANTA | Moda |

Vaulted Table

Vaulted table is an exploration towards creating new structural and form languages using timber combined with computational design and digital fabrication techniques.

The project began with the production of the main volume creating a shape which is dynamically relaxed so to reduce structural stresses and making it appropriate for being made out of timber.

Although the form looks like a hand modeled sculpture the table structure is based on dynamic relaxation method (form-finding) where the aim is to find a geometry where all forces are in equilibrium.

In order to enhance the material properties and the space configuration has been applied a series of apertures deriving from a leaf pattern and parametrically controlled re-configuring the weight and volume dynamically.

The Vaulted table was produced on a 5-axis SCM router with dedicated custom software optimizing the tool-path generation to remove the most material with the least effort. The total machining time to was calculated around 300 hours utilizing 2 cubic meters of timber for a production of a total finished surface of 9 square meters.

Frequency Wall

This is the installation on show at the SCM Group stand for Ligna: an architectural work in poplar OSB by IPAN (an Italian company that is the only one producing it in Europe).

The name of the structure is inspired by the frequency of the sound waves generated by the noise of cutters as they work the wood, perfectly reproduced by the fascinating assembly of over 850 different shapes. A work made possible by an Scm Tech boring/milling machine, that once again demonstrates the

potential of our machining centres as tools able to turn ingenious ideas into reality.

The shapes that make up the Frequency Wall were assembled by Naldini Arredamenti, a Forlì company linked to SCM Group by a long, fruitful collaboration - the latest step being the investment in a machining centre to complete the 100% SCM range of machines.

Frequency wall

designed by bloomlab architecture

machined with SCM Tech Z5, SCM Group

manufactured by Naldini Arredamenti

with poplar OSB by IPAN

Easter Eggs

Eggs designed by BLOOMLAB, using cedar wood from Riva 1920. The machining was performed with SCM Group 6-axis technology. Displayed at the Technodomus 2012 fair in Rimini and at Ligna in these days.