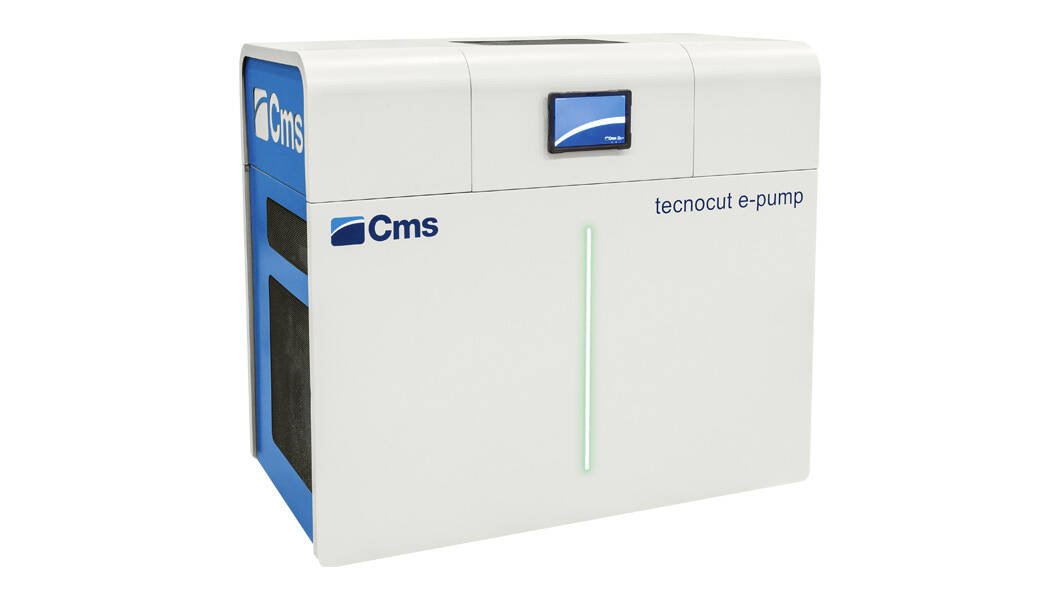

tecnocut e-pump

(512) 931-1962

HYBRID INTENSIFIER

TECNOCUT E-PUMP is the latest innovation in the range of CMS Plastic Technology intensifiers created as a continuation of the quest by CMS for efficiency, performance, energy consumption and low environmental impact in the world of pressure intensifiers for waterjet cutting applications.This new project was carried out entirely in the CMS engineering department and has given rise to an innovative product that combines the power density of a hydraulic pump with the energy efficiency of a direct-drive mechanical architecture. The simplicity of the system translates into a significant reduction in components: up to 95% compared to a conventional hydraulic intensifier.

Tecnocut e-pump exploits an electrohydrostatic unit connected directly to long-stroke pressure multiplier cylinders, achieving an operating

efficiency of more than 31% compared to hydraulic intensifiers. The intensifier has an on-board intelligence with portable tablet (Wi-Fi) and touch display for monitoring and controlling operating parameters and performing diagnostics on hydraulic and high-pressure components.

Tecnocut e-pump can be installed on any cutting table, even third-party ones.

VERY HIGH EFFICIENCY

The innovative tecnocut e-pump technology guarantees 31% better efficiency compared to a conventional hydraulic intensifier, partly due to a 95% reduction in hydraulic components and the direct hydraulic unit interface to eliminate pressure losses and long-term wear.

MAXIMUM ENERGY SAVINGS

-37% electricity consumption due to a combination of cutting cycles and rapid movements. The hybrid double-acting pressure pump with direct connection is optimized to reduce consumption, thanks to the use of a brushless servomotor controlled by an inverter. The primary motor and auxiliary motors controlled by inverters allow tecnocut e-pump to adapt better to the working conditions and eliminate starting current peaks.

WI-FI TABLET WITH WEB HMI

The intensifier is controlled by an industrial PLC in the electrical cabinet in order to interface with CMS cutting tables, as well as third party ones.

The HMI control interface is accessible from the10.4” Wi-Fi tablet and offers:

-remote diagnostics

- power management and control

- management and control of the cycle numberper cylinder

- electronic cutting pressure control

| TECHNICAL SPECIFICATIONS * | |

| POWER CONSUMPTION (0.38 ORIFICE AT 3800 BAR) | 30 kW |

| MAXIMUM POWER CONSUMPTION WITH CLOSED HEAD | 2.4 kW |

| MAXIMUM OPERATING PRESSURE | 4130 bar |

| MAXIMUM WATER FLOW RATE AT 3700 BAR | 5 l/min |

| MAXIMUM ORIFICE DIAMETER AT 3700 BAR | 0.40 mm |

| OVERALL DIMENSIONS L X W X H | 1666x906x1529 mm |

| WEIGHT | 1400 Kg |

| VOLTAGE (THREE-PHASE) | 400 V 50/60 Hz |

| OIL TANK CAPACITY | 13 L |

| PRESSURE ATTENUATOR CAPACITY | 1.15 L |

| CYLINDER STROKE | 200 mm |

| REQUIRED INLET WATER TEMPERATURE (ACCEPTABLE MIN – MAX) | 5 - 25 °C |

| NOMINAL ENVIRONMENT TEMPERATURE (ACCEPTABLE MIN – MAX) | 5 - 40 °C |

| NOMINAL NOISE | 70 db |

* BFT Technology. The technical data may vary with different configurations

Fill out the online form to be contacted by a salesperson