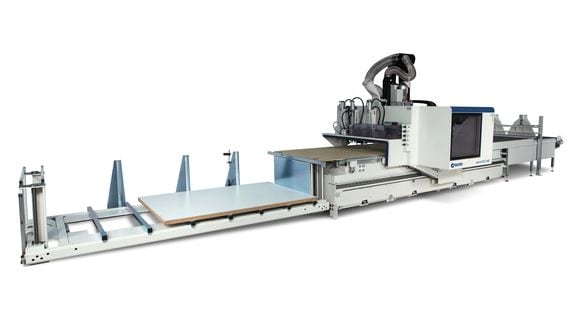

morbidelli x200/x400

(512) 931-1962

The new generation of Nesting CNC machining centers meets the needs of a market increasingly oriented towards flexible and batch-1 production, combining excellent performance, maximum configurability with increased flexibility and productivity.

Every detail is designed to make any performance accessible, leading to efficiency, quality and business evolution.

NOT ONLY NESTING:

FLEXIBLE

Any machining process without removing the spoilboard and even in 3D thanks to the X-PODs and the JQX (Just Quality eXtreme)

5-axis electrospindle.

FASTER THAN ANY OTHER MACHINE

Nesting processing at 50 m/min, saves 60% of time on drilling cycles thanks to the new drilling heads (also with double saw blade) and less than 15” for the tool change thanks to the FAST tool changer directly installed on the mobile unit.

MAXIMUM HOLDING:

TOP QUALITY

Thanks to the X-Vacuum System, the vacuum is condensed into the area of the worktable where the workpiece is being processed.

Perfect to process small workpieces or highly breathable materials.

| x200 | x400 | ||||

| Working areas | |||||

| X-Y axes dimensions | mm | 2556x1296 3156x1596 3756x1596 3756x1896 3156x2216 4356x2216 |

|||

| Axes | |||||

| Vectorial speed X-Y axes | m/min | 84 (Pro-Space) 113 (Pro-Speed) |

|||

| Z axis panel passage | mm | 150 | 180 | ||

| Routing unit | |||||

| Motor power (3-4 axes up to) | kW (hp) | 15 (20,5) | |||

| Motor power (5-axis up to) | kW (hp) | - | 13,5 (18,4) | ||

| Rotation speed (up to) | rpm | 24000 | |||

| Available tools on tool changer (up to) | positions | 38 | 53 | ||

| Drilling unit | |||||

| Independent vertical spindles (up to) | n. | 21 | |||

| Independent horizontal spindles (up to) | n. | 12 | |||

| Rotation speed (up to) | rpm | 8000 | |||

| Integrated blades | n. | 2 | |||

| Integrated blade in X, diameter | mm | 125 | |||

| 0-90° blade unit | |||||

| Motor power (up to) | kW (hp) | 2,2 (3) | |||

| Rotation speed (up to) | rpm | 6000 | |||

| Auxiliary routing unit | |||||

| Motor power (up to) | kW (hp) | 5,4 (7,4) | |||

| Rotation speed (up to) | rpm | 24000 | |||

Fill out the online form to be contacted by a salesperson