athena

(512) 931-1962

High speed 5-axis CNC machining center

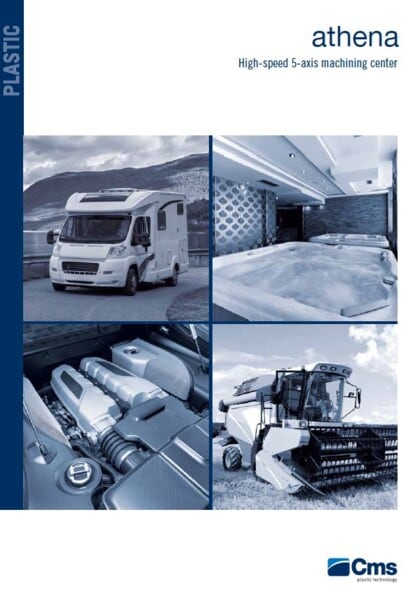

Movable-bridge machining center specifically designed for high speed processing of plastic and composite materials, providing exceptional motion dynamics to ensure high productivity. The advanced structural design avoids machining vibration and achives excellent finishing quality:

- very large working areas for the maximum production freedom

- broad variety of working areas (single zone or tandem cycle)

- the compact design enables handling and transport without removing any mechanical part, ensuring reduced time for machine restarting

- Smart4Cut programming system is dedicated to the optimization of the trimming path. Interactive software, a portable keypad with joystick and touch screen provide the operator the ability to easily manage all the CNC functions. Cutting programs canbe created by starting from the 3d model or directly from the sample piece fitted on the machine,automatically eliminating all unnecessary movements and reducing the cycle time to a

minimum.

athena is available also with rotating tables (TR) and with removable tables APC (Automatic Pallet Change).

REDUCTION IN CYCLE TIME RESPONSIVENESS AND SPEED WHERE AND WHEN NEEDED

Dedicated dynamics, during both acceleration and braking, for all cutting cycle phases.

13% reduction in comprehensive machining times due to shorter repositioning spaces required between one phase and the next.

FASTER PROGRAMMING AND CONTOURING

Avoids any repositioning operations thanks to the CX5 operating unit, characterized by the the largest rotary XY axis on the market.

15% reduction in cutting times and programming of contouring cuts

OPTIMIZATION AND USE OF WORK VOLUMES WITH NON-CONFIGURABILITY LIMITATIONS

Minimum space taken up and maximum use of factory space in proportion to workable cubic space for all versions. Its compact, hard structure was designed to grip to the working stroke as much as possible. Pendulum processing available with Athena’s vast configurability, extractable (APC) and rotating (TR) tables make it the perfect solution for trimming plastic materials.

|

ATHENA: STROKES AND SPEED |

||||||||||

|

MODEL |

FAST AXIS |

STROKES |

||||||||

|

(mm) |

(°) |

(m/min) |

(°/min) |

|||||||

|

X |

Y |

Z |

B |

C |

X |

Y |

Z |

B |

C |

|

|

2015 |

2370 |

1500 |

1200 |

±120 |

± 360 |

90 |

60 |

40 |

10800 |

|

|

3015 |

3370 |

|||||||||

|

4015 |

4370 |

|||||||||

|

5015 |

5370 |

|||||||||

|

3020 |

3370 |

2000 |

1200 |

±120 |

± 360 |

90 |

60 |

40 |

10800 |

|

|

4020 |

4370 |

|||||||||

|

5020 |

5370 |

|||||||||

|

4025 |

4370 |

2500 |

1200 |

±120 |

± 360 |

90 |

60 |

40 |

10800 |

|

|

5025 |

5370 |

|||||||||

| WORKING UNITS AND ELECTROSPINDLES | ||||||

| MODEL | NOMINAL POWER (S1) | MAX POWER (S6) | MAX RPM | TORQUE (S1) | TOOL HOLDER | COOLING |

| CX5 | 8,5 kW | 10 kW | 24000 rpm | 6,8 Nm | HSK 63F | Liquid |

| CX5 10 | 10 kW | 12 kW | 24000 rpm | 8 Nm | HSK 63F | Liquid |

| CX5 8 | 8 kW | 9 kW | 40000 rpm | 5,2 Nm | HSK 32E | Liquid |

Fill out the online form to be contacted by a salesperson