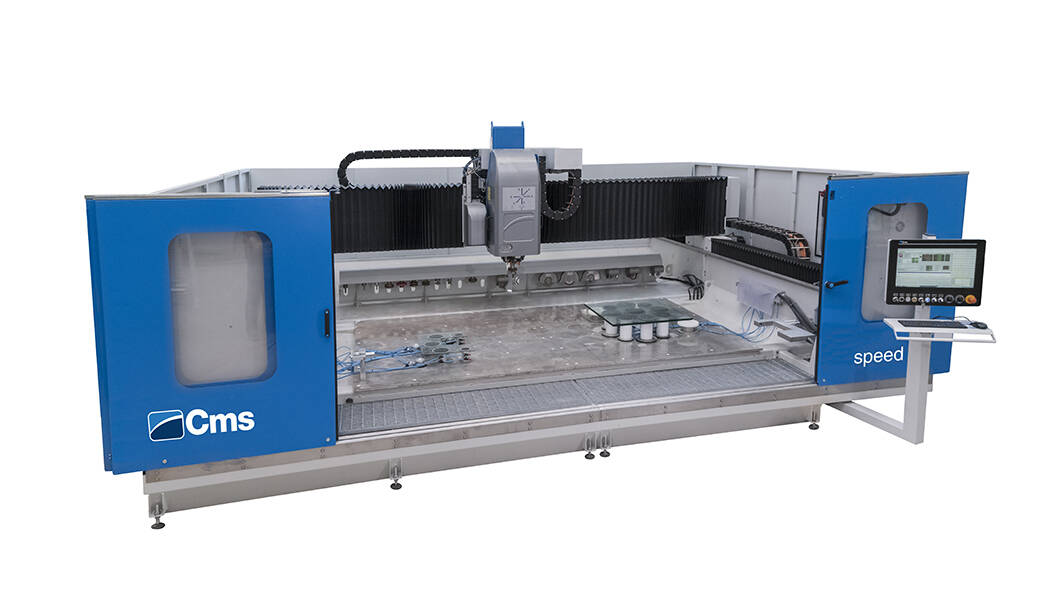

speed

(512) 931-1962

BREMBANA SPEED 13

3-4 interpolated axes machining center

Designed for the machining of glass sheets and other materials, it can quickly and accurately perform grinding, polishing, drilling, milling, cutting with disk, engraving, writing and 5° beveling operations. It is the most compact and versatile CMS machining center, suitable especially for small and medium workshops.

• the mobile bridge gantry system with linear axis movement, ensures motion accuracy and easy loading/unloading of heavy workpieces

• linear axis speeds up to 54m/min, to reduce tool change times and axis positioning operations

• the electrospindle is CMS technology, liquid-cooled and with power up to 30kw in order to ensure maximum performance and ideal operating conditions

• the work surface is made of 15 mm thick solid alluminum for better stability and durability

BREMBANA SPEED MB

3-4 interpolated axes machining center

3-4 axes (on request) Numerically Controlled machining center for the processing of thin and thick flat glass sheets for both laminated and bullet-proof glass. It carries out any type of grinding, polishing, drilling, milling, cutting with disk, engraving, writing and 5° beveling operations.

• Y-axis gantry system provides the crossbeam motion via two brushless motors synchronized by the NC, in order to ensure maximum accuracy and reduction in positioning errors that are due to mechanical elasticity

• large-sized duralluminum work surface. The above ground height of 500 mm facilitates access to the machine and makes the glass sheet loading/unloading operations easier

• ultra-thick and normalized electrowelded ribbed steel monolithic base ensures sturdiness and rigidity for heavy-duty operations and durability

• the machine is adaptable to any need due, thanks to the high configurability of the tool rack

• dynamic compensation of the polishing wheel for better machining quality

• working water collection tank integrated with the base which reduces the machine’s footprint

COMFORTABLE LOADING

Thanks to the automatic doors the machine can be loaded and downloaded automatic from an automatic charger, while ensuring the total occupational safety for the operator.

SOLID ALUMINUM WORKTOP

Duralumin worktop 18 mm thick, for greater stability and durability. The table allows being adjusted more than 10 times.

DOUBLE PRODUCTIVITY

In the Twin version, thanks to the independent double head, productivity increases by up to 53%. Speed Twin, the only machine with two heads and 4 axes on the market, allows simultaneous drilling on identical pieces.

| X AXIS STROKE | 3800 mm / 149 in | ||

| Y AXIS STROKE |

1740 ÷ 7200 mm / 68 ÷ 283 in (configurations with Y>283 in are available) |

||

|

Z AXIS STROKE |

420 ÷ 900 mm / 16 ÷ 35 in |

||

| MAXIMUM XY WORKING DIMENSIONS | It changes according to the configuration | ||

| ROTATING AXIS (OPTIONAL) | C | 360° Stepless | |

| TOOL CHANGE POSITIONS | 12÷120 | ||

| ELECTROSPINDLE | |||

| POWER | 13,5 KW / 18 HP (S1) 21 KW / 28 HP (S6) |

30 KW / 40 HP (S1) 36 KW / 48 HP (S6) |

|

|

REVOLUTION |

0 ÷ 15000 rpm |

0 ÷ 12000 rpm | |

| OVERALL DIMENSIONS | A B H |

3700 ÷ 9260 mm / 146 ÷ 365 in 7260 mm / 286 in open doors from 2535 mm / 100 in |

|

| ELECTRICAL CABINET |

Integrated in the base |

||

| WEIGHT | 7000 ÷ 15000 Kg / 15432 ÷ 33070 lb | ||

Fill out the online form to be contacted by a salesperson