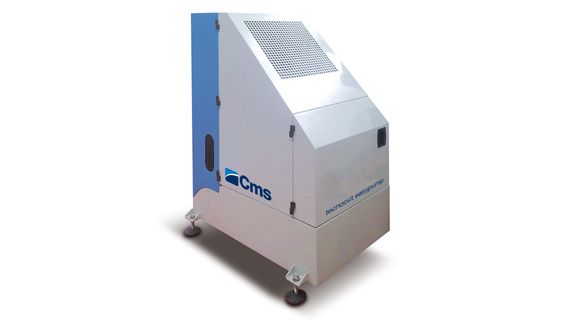

tecnocut jetpower evo

(512) 931-1962

High pressure intensifier

CMS brought about a new concept in ultrahigh pressure intensifiers, enhaced by technological solutions designed to satisfy the needs of most demanding users. This new technology is based on an intensifier equipped with several pressure multipliers independent, parallel and electronically synchronized. This innovative solution results in an everconstant pressure avoiding any drops typical of traditional opposecylinder intensifiers.

- highly constant pressure and no accumulator

- higher stability of the dynamic pressure signal as a guarantee to achieve a superior quality cut

- lower wear of all machining centre high-pressure circuit components, longer life of materials and reduced maintenance

- the technology of independent cylinders allows shutdown of any cylinder that needs servicing

- this means the operator can choose the maintenance schedule, without stop the machine

- software-based electronic control of cutting pressure

- electronic monitoring of temperature, pressure and filter clogging

- hydraulic pump with variable flow rates

- hydraulic cylinders return circuit with independent pump

- air/Oil exchanger for hydraulic circuit cooling (water/oil option)

- it can be connected to any Stand Alone cutting system

CONSTANT OUTPUT PRESSURE FOR BETTER CUTTING QUALITY

Hydraulic intensifier with 2 or 3 independent and electronically syncronized parallel cylinders to guarantee a constant signal of output pressure without the use of attenuator.

REDUNDANT ARCHITECTURE: LESS MACHINE DOWNTIME

The technology with 3 independent cylinders allows the bypass of a single cylinder that needs maintenance, while the machine is working, avoiding unnecessary downtime.

LESS MAINTENANCE COSTS

The parallel cylinders architecture is designed for a low cycle frequency that reduce the high pressure components wear and consequently the maintenance costs.

| Tecnocut Jetpower evo 40 HP | Tecnocut Jetpower evo 60 HP | |

| Power | 30 kW / 40 HP | 45 kW / 60 HP |

| Multipliers | 2 | 3 |

| Max water pressure | 4150 bar / 60.000 psi | 4150 bar / 60.000 psi |

| Max water flow rate | 2,7 lpm / 0,71 gpm | 5 lpm / 1,32 gpm |

| Max diam orifices | 0,30 mm / 0,012 in | 0,40 mm / 0,016 in |

| Voltage | 400V +/- 5% 50-60 Hz (Diverse tensioni e frequenze a richiesta)(Different voltages and frequencies on request) | |

Fill out the online form to be contacted by a salesperson