IWF 2024

06-09.08.2024 Atlanta, Georgia (US)

SCM to bring frontline wood innovation to IWF 2024

Georgia World Congress Center, Atlanta | August 6-9 – Booth 6953

Win the new SCM MAKER

SCM is proud to introduce a new revolutionary product: the SCM MAKER - portable CNC

What will you make today?

Thank you to all for unleashing your creativity and participating in our official contest for your chance to win. The winner will be announced at IWF and on social media on Friday, August 9th at 11 AM

For each submission, SCM will donate $100 to the Semper Fi & America's Fund.

SCM North America is a long-standing proud supporter of the Semper Fi & America's Fund, a non-profit organization that supports combat-wounded and critically ill service members... for life.

Robotic Cell Seminars

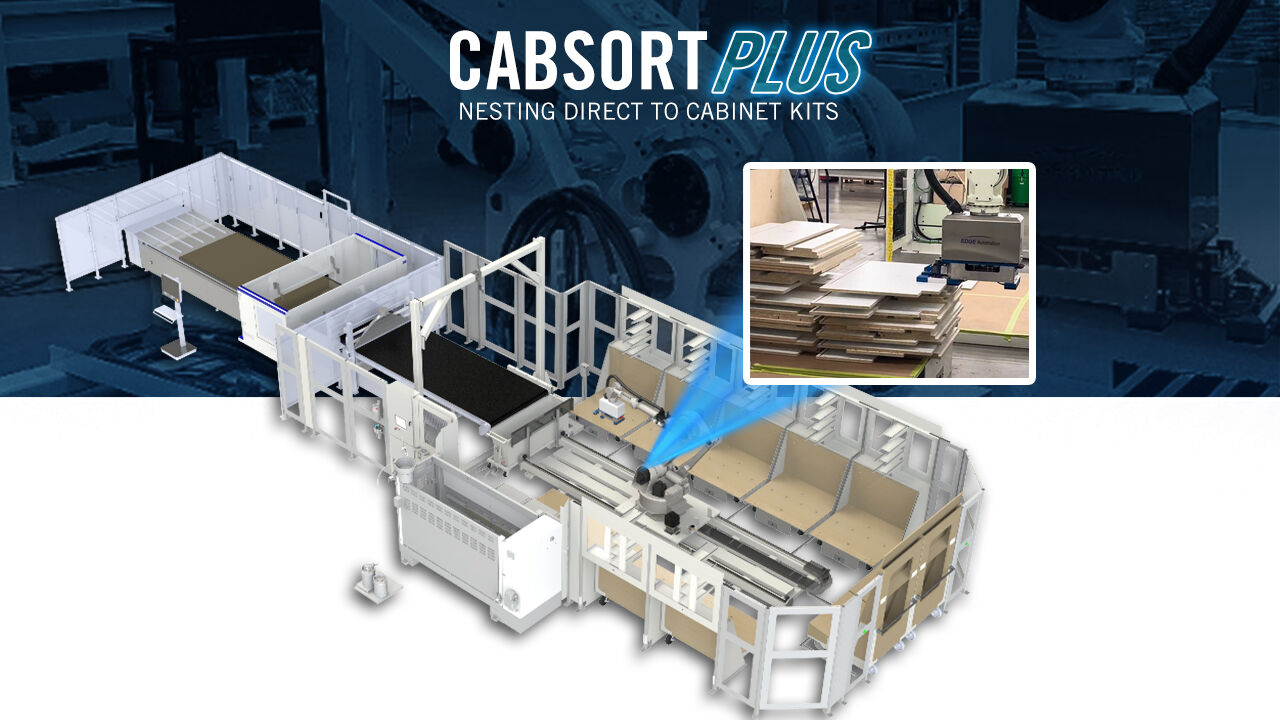

The Lean Cell features the new Morbidelli X200 developed specifically for high-speed nesting and robotic sorting and stacking as well as doweling. SCM will show the added dimension of SORTING. The cell will group end panels and cabinet parts in a way to keep like cabinet parts together and all aligned on the same axis for edgebanding.

The robot is mounted on a 7th axis. This robotic cell will use an improved intelligent vision-guided end-of-arm-tool to identify and pick up each panel from a nest and process according to the label barcode data.

The robotic cell will sort parts based on part family as well as common dimensions through our advanced software application. SCM has a registration fixture to allow parts to be aligned for perfect stacks.

Additionally, SCM placed the robot on a linear 7th axis rail system to allow for maximum sorting capabilities while keeping the cell footprint minimal. The cell has been redesigned so that the material carts placed within the cell will be used for sorting all nested panels into defined stacks and integrated into the cell using safety interlocks.

The cell can do the work of 3 people with one person tending 25% of the time.

Robotic Cell Demo Schedule from Tuesday, August 6th, to Thursday, August 8th:

11:00 am

2:30 pm

Robotic Cell Demo Schedule on Friday, August 9th:

11:00 am

Blade Off and startech cn k

“blade off”: the innovative safety system designed by SCM and applied to the circular saws. Thanks to the smart sensors it prevents accidental contact between the human body and the blade by automatically excluding it and stopping the execution of the program without damaging any machine component.

startech cn k: compact 3-axis NC machining centre ables to carry out all types of milling, decorations, engraving, signboard creation and 3D model prototyping.

The only one in its category equipped with a 2,4 kW electrospindle. The integral cabin ensures absolute protection for the operator and keeps the surrounding environment clean.

Very simple to be programmed, thanks to the "Open" virtual human-machine interface capable of importing G-code from any CAD/CAM software.

We are thrilled to announce that we have submitted our SD90 DMC Variable Drum Unit for consideration for the prestigious IWF Challengers Distinguished Achievement Award.

This award is renowned worldwide for honoring exceptional companies that have distinguished themselves through the development of innovative technology in products, services, or manufacturing techniques aimed at advancing the industry.

The IWF Challengers Distinguished Achievement Award is an internationally recognized competition that celebrates companies that have pioneered new and innovative technologies, making significant contributions to the industry. Participation in this competition is open to all exhibitors of IWF 2024, and we are proud to be among the forward-thinking companies vying for recognition.

Our submission of the SD90 DMC Variable Drum Unit reflects our commitment to innovation and excellence in manufacturing technology.

We are honored to be part of such a prestigious competition and eagerly anticipate the opportunity to showcase our groundbreaking technology on a global stage.

Winning the IWF Challengers Distinguished Achievement Award would not only be a tremendous honor for our company but also a validation of our relentless pursuit of innovation and excellence.

The Equipment Finance Advantage

SCM Equipment Financing can finance from any manufacturer with the most competitive rates in the industry. From software to dust collection systems to tooling and machinery, if it fuels your business, we can finance it.

Detailed informations will be available soon

Digital Services and Softwares

At IWF 2024, SCM will present its latest Industry 4.0 innovations with the complete range of solutions within the Maestro Digital Systems suite.

Visitors will have the opportunity to see and interact with our Maestro Software systems, which bridge the gap between human and machine.

Every package is tailored to meet the demands of industry, implementing all the leading innovations of the market and introducing their own, making the most efficient use of an employee's skills and time.

SCM's very latest advancements in Digital Services will demonstrate all the benefits of a connected plant. Control Room will analyze machine diagnostic data in real time to generate smart and proactive maintenance requests. Monitor machine status from anywhere in the world, schedule maintenance tasks, analyze performance data, and schedule service requests, all from your smartphone or browser with the Maestro Connect platform.

The new X Series Machines

See the new machines launch at IWF

Machines at IWF

olimpic k 560

Single-sided automatic edge bandersHigh performance and versatility: olimpic k 560 is designed for companies requiring to process many panels per day even though they may be different from one to another. olimpic k 560 has several solutions that guarantee always the best machining on...

stefani kd

Single-sided automatic edge bandersContinuous and versatile solutions for quality machining are the distinctive features of stefani kd. All you would expect from an edge banding machine: the use of EVA and Polyurethane glue thanks to the SGP glue pot, machining units with electronic axes...

dmc mb 90

Automatic sanding and calibrating machinesdmc mb 90 is the ideal solution for the finishing of routed MDF panels, assembled kitchen cabinet doors, doors and windows and similar profiled parts (picture frame strips, cableways, matchboardings, skirting boards). Parts can be rough or painted.

dmc system t

Automatic sanding and calibrating machinesdmc system t project is the maximum expression of versatility and is aimed at companies that need to carry out particularly complex calibration and sanding machining with high productivity. We highlight the machining of solid wood doors, calibrations...

dmc sd 90

Automatic sanding and calibrating machinesMaximum performance for companies increasing production. Designed for the medium to high industrial companies that require diversified machining, dmc sd 90 satisfies all calibrating and sanding requirements, by offering a wide range of technological...

OMAL HBD 1300 1H

CNC Machining Centers for routing and drillingThe HBD 1300 1H is an Open Frame CNC machine to drill, glue and insert dowels with a 1300mm (51”) working field. The center and side fences are retractable in order to process up to an 8’ length piece in two cycles. With the OMAL “Sure Shot”...

me 40

Edge BandersSingle-phase or 3-phase edge bander, 3mm tooling with dual-head diamond pre-milling unit and radius feature with interchangeable and spare glue pot unit, high-frequency motors on end trim and profile trimming stations with both vertical and horizontal copy wheels, edge and glue scrape units, and buffing unit

minimax cu 410es

Universal combination machinesSingle-phase 8 horsepower five-function machine with 16" Tersa or Xylent cutterhead jointer planer, 8.5ft stroke sliding table saw with 14" blade, 4-speed shaper with 1.25" interchangeable tilting spindle, dado capability, mortiser, readouts, and powered movement

ergon nt

CNC Nesting Machining Centers for routing and drillingCnc machining center with parallel heads designed for a wide range of applications, from panels in nesting to doors, stairs and solid wood parts manufacturing. ergon nt is the ideal solution for integration in line with automatic loading and unloading...

accord 600

CNC Machining Centers for routing and drillingaccord 600 represents the best design solution that does not compromise on performance when machining doors, windows, stairs and solid wood elements as well as typical furniture sector requirements. In order to fully reduce production times, the...

ergon nt

CNC Nesting Machining Centers for routing and drillingCnc machining center with parallel heads designed for a wide range of applications, from panels in nesting to doors, stairs and solid wood parts manufacturing. ergon nt is the ideal solution for integration in line with automatic loading and unloading...

OMAL HG2

CNC Machining Centers for routing and drillingThe HG2 is an Automatic Drilling and Inserting machine for hinges. The machine has a working field of 1500mm (59”) with adjustable reference stops for left and right door reference. The first head is fixed and second head can be manually moved by a push...