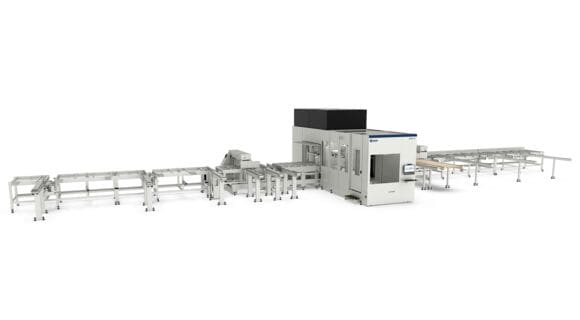

oikos x4

(512) 931-1962

oikos x4 is the new 6-axis CNC machining centre, designed for the rapid and precise processing of camber beams with maximum section of 1250x300 mm. It is ideal for the construction of large building roofs (warehouses or supermarkets) and public structures. This innovative solution for the wood construction industry offers new business opportunities and environmental benefits.

From Mass Timber to Smart Timber

Camber beams are engineered components made of laminated wood (Glulam), glued and pressed with a slight longitudinal curvature, typically a few millimeters over a length of 10 meters. This curvature, almost imperceptible to the naked eye, ensures that the beam becomes straight under load, resulting in up to 10% material savings in industrial applications.

INNOVATIVE PROCESSING

The ability to process camber beams with precision and full automation, thanks to four interpolated clamps with full stroke, two positioned on the loading side and two on the unloading side.

UNLOCKING EFFICIENCY

The 6-axis operating unit, equipped with an 18-position tool store, allows for rapid tool changes and mask time operations, thus increasing the overall efficiency and speed of machining processes.

SUPERIOR PRECISION AND QUALITY

The robust structure ensures high precision and excellent stress absorption during the machining process, guaranteeing superior quality results.

EMPOWERING PRODUCTION

Maestro beam&wall is the SCM software, compatible with the most widely used CAD design tools in the wood construction industry. It allows for programming both in the office and directly on the machine via Maestro active beam&wall, the new HMI software that offers simple and intuitive control and optimization of the production flow. The IoT platform Maestro connect is the application for monitoring the performance and productivity of connected machines.

| Workpiece dimensions | ||

| Length max. | mm | 9.000 - 13.500 - 19.000 + extensions |

| Cross-section max. | mm | 1.250 x 300 |

| Cross-section min. | mm | 50 x 20 |

| Weight max. | kg | 2.500 |

| Main operating unit | ||

| Axes (workpiece faces) | N° | 6 |

| Power max. (S1) | kW | 13 |

| Sawblade diameter | mm | 500 |

| Compatibility with tool store | yes | |

| Tool store | ||

| Positions | N° | 18 |

Пожалуйста, заполните форму запроса, и мы свяжемся с Вами в ближайшее время